Bitumen is a sticky, black, highly viscous liquid or semi-solid form of petroleum. In the U.S., it is commonly referred to as asphalt. It may be found in natural deposits or may be a refined product, and is classed as a pitch. Before the 20th century, the term asphaltum was also used. The word is derived from the Ancient Greek ἄσφαλτος ásphaltos. The largest natural deposit of bitumen in the world, estimated to contain 10 million tons, is the Pitch Lake in southwest Trinidad.

Highway engineering is an engineering discipline branching from civil engineering that involves the planning, design, construction, operation, and maintenance of roads, bridges, and tunnels to ensure safe and effective transportation of people and goods. Highway engineering became prominent towards the latter half of the 20th century after World War II. Standards of highway engineering are continuously being improved. Highway engineers must take into account future traffic flows, design of highway intersections/interchanges, geometric alignment and design, highway pavement materials and design, structural design of pavement thickness, and pavement maintenance.

A road surface, or pavement, is the durable surface material laid down on an area intended to sustain vehicular or foot traffic, such as a road or walkway. In the past, gravel road surfaces, hoggin, cobblestone and granite setts were extensively used, but these have mostly been replaced by asphalt or concrete laid on a compacted base course. Asphalt mixtures have been used in pavement construction since the beginning of the 20th century and are of two types: metalled (hard-surfaced) and unmetalled roads. Metalled roadways are made to sustain vehicular load and so are usually made on frequently used roads. Unmetalled roads, also known as gravel roads, are rough and can sustain less weight. Road surfaces are frequently marked to guide traffic.

Asphalt concrete is a composite material commonly used to surface roads, parking lots, airports, and the core of embankment dams. Asphalt mixtures have been used in pavement construction since the beginning of the twentieth century. It consists of mineral aggregate bound together with bitumen, laid in layers, and compacted. The process was refined and enhanced by Belgian-American inventor Edward De Smedt.

Heavy equipment or heavy machinery or Earthmover refers to heavy-duty vehicles specially designed to execute construction tasks, most frequently involving earthwork operations or other large construction tasks. Heavy equipment usually comprises five equipment systems: the implement, traction, structure, power train, and control/information.

Permeable paving surfaces are made of either a porous material that enables stormwater to flow through it or nonporous blocks spaced so that water can flow between the gaps. Permeable paving can also include a variety of surfacing techniques for roads, parking lots, and pedestrian walkways. Permeable pavement surfaces may be composed of; pervious concrete, porous asphalt, paving stones, or interlocking pavers. Unlike traditional impervious paving materials such as concrete and asphalt, permeable paving systems allow stormwater to percolate and infiltrate through the pavement and into the aggregate layers and/or soil below. In addition to reducing surface runoff, permeable paving systems can trap suspended solids, thereby filtering pollutants from stormwater.

This page is a list of construction topics.

A road roller is a compactor-type engineering vehicle used to compact soil, gravel, concrete, or asphalt in the construction of roads and foundations. Similar rollers are used also at landfills or in agriculture.

Full depth recycling or full depth reclamation (FDR) is a process that rebuilds worn out asphalt pavements by recycling the existing roadway.

Soil cement is a construction material, a mix of pulverized natural soil with small amount of portland cement and water, usually processed in a tumbler, compacted to high density. Hard, semi-rigid durable material is formed by hydration of the cement particles.

A trencher is a piece of construction equipment used to dig trenches, especially for laying pipes or electrical cables, for installing drainage, or in preparation for trench warfare. Trenchers may range in size from walk-behind models, to attachments for a skid loader or tractor, to very heavy tracked heavy equipment.

Terex Corporation is an American worldwide manufacturer of lifting and material-handling plant for a variety of industries including construction, infrastructure, quarrying, recycling, energy, mining, shipping, transportation, refining and utilities. The company's major business segments include aerial work platforms, construction cranes, bulk-material hauling machines, road-paving machines, and container-port cranes.

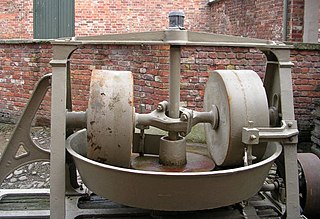

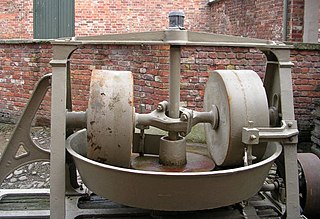

A pugmill or pug mill is a machine in which clay or other materials are mixed into a plastic state or a similar machine for the trituration of ore. Industrial applications are found in pottery, bricks, cement and some parts of the concrete and asphalt mixing processes. A pugmill may be a fast continuous mixer. A continuous pugmill can achieve a thoroughly mixed, homogeneous mixture in a few seconds, and the right machines can be matched to the right application by taking into account the factors of agitation, drive assembly, inlet, discharge, cost and maintenance. Mixing materials at optimum moisture content requires the forced mixing action of the pugmill paddles, while soupy materials might be mixed in a drum mixer. A typical pugmill consists of a horizontal boxlike chamber with a top inlet and a bottom discharge at the other end, 2 shafts with opposing paddles, and a drive assembly. Some of the factors affecting mixing and residence time are the number and the size of the paddles, paddle swing arc, overlap of left and right swing arc, size of mixing chamber, length of pugmill floor, and material being mixed.

Rubberized asphalt concrete (RAC), also known as asphalt rubber or just rubberized asphalt, is noise reducing pavement material that consists of regular asphalt concrete mixed with crumb rubber made from recycled tires. Asphalt rubber is the largest single market for ground rubber in the United States, consuming an estimated 220,000,000 pounds (100,000,000 kg), or approximately 12 million tires annually.

Crushed stone or angular rock is a form of construction aggregate, typically produced by mining a suitable rock deposit and breaking the removed rock down to the desired size using crushers. It is distinct from naturally occurring gravel, which is produced by natural processes of weathering and erosion and typically has a more rounded shape.

Rubblization is a construction and engineering technique that involves saving time and transportation costs by reducing existing concrete into rubble at its current location rather than hauling it to another location. Rubblization has two primary applications: creating a base for new roadways and decommissioning nuclear power plants.

Diamond grinding is a pavement preservation technique that corrects a variety of surface imperfections on both concrete and asphalt concrete pavements. Most often utilized on concrete pavement, diamond grinding is typically performed in conjunction with other concrete pavement preservation (CPP) techniques such as road slab stabilization, full- and partial-depth repair, dowel bar retrofit, cross stitching longitudinal cracks or joints and joint and crack resealing. Diamond grinding restores rideability by removing surface irregularities caused during construction or through repeated traffic loading over time. The immediate effect of diamond grinding is a significant improvement in the smoothness of a pavement. Another important effect of diamond grinding is the considerable increase in surface macrotexture and consequent improvement in skid resistance, noise reduction and safety.

CMI Roadbuilding, Inc. of Oklahoma City began in 1961, when engineers headed by Bill Swisher started looking for new methods in the road building industry. Little had changed since the early 1900s in the methods of building roads, however, labor costs were skyrocketing and inflation meant taxpayers dollars were buying less and less. In the same period Society was becoming increasingly more mobile creating demand for better roads and highways. The CMI group believed that many road failures were due to poor riding surface which was mainly caused by inaccuracies in the subgrade.

Pavement milling is the process of removing at least part of the surface of a paved area such as a road, bridge, or parking lot. Milling removes anywhere from just enough thickness to level and smooth the surface to a full depth removal. There are a number of different reasons for milling a paved area instead of simply repaving over the existing surface.

Wirtgen Group is an internationally operating German company in the construction industry. The company's core business is the development and production of machinery for road construction and maintenance.