3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together, typically layer by layer.

Organ printing utilizes techniques similar to conventional 3D printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3D object is produced. In the case of organ printing, the material being used by the printer is a biocompatible plastic. The biocompatible plastic forms a scaffold that acts as the skeleton for the organ that is being printed. As the plastic is being laid down, it is also seeded with human cells from the patient's organ that is being printed for. After printing, the organ is transferred to an incubation chamber to give the cells time to grow. After a sufficient amount of time, the organ is implanted into the patient.

Multiphoton lithography of polymer templates has been known for years by the photonic crystal community. Similar to standard photolithography techniques, structuring is accomplished by illuminating negative-tone or positive-tone photoresists via light of a well-defined wavelength. A critical difference is, however, the avoidance of photomasks. Instead, two-photon absorption is utilized to induce a dramatic change in the solubility of the resist for appropriate developers.

Three-dimensional composites use fiber preforms constructed from yarns or tows arranged into complex three-dimensional structures. These can be created from a 3D weaving process, a 3D knitting process, a 3D braiding process, or a 3D lay of short fibers. A resin is applied to the 3D preform to create the composite material. Three-dimensional composites are used in highly engineered and highly technical applications in order to achieve complex mechanical properties. Three-dimensional composites are engineered to react to stresses and strains in ways that are not possible with traditional composite materials composed of single direction tows, or 2D woven composites, sandwich composites or stacked laminate materials.

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure.

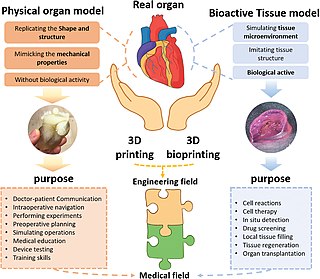

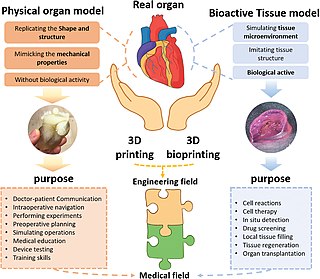

Three dimensional (3D) bioprinting is the utilization of 3D printing–like techniques to combine cells, growth factors, bio-inks, and/or biomaterials to fabricate biomedical parts that imitate natural tissue characteristics, form functional biofilms, and assist in the removal of pollutants. 3D bioprinting has uses in fields such as wastewater treatment, environmental remediation, and corrosion prevention. 3D bioprinting can produce functional biofilms which can assist in a variety of situations. The 3D bioprinted biofilms host functional microorganisms which can facilitate pollutant removal. Generally, 3D bioprinting can utilize a layer-by-layer method to deposit materials known as bio-inks to create tissue-like structures that are later used in various medical and tissue engineering fields. 3D bioprinting covers a broad range of bioprinting techniques and biomaterials. Currently, bioprinting can be used to print tissue and organ models to help research drugs and potential treatments. Nonetheless, translation of bioprinted living cellular constructs into clinical application is met with several issues due to the complexity and cell number necessary to create functional organs. However, innovations span from bioprinting of extracellular matrix to mixing cells with hydrogels deposited layer by layer to produce the desired tissue. In addition, 3D bioprinting has begun to incorporate the printing of scaffolds which can be used to regenerate joints and ligaments.

Fused filament fabrication (FFF), also known as fused deposition modeling, or filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use.

Bio-inks are materials used to produce engineered/artificial live tissue using 3D printing. These inks are mostly composed of the cells that are being used, but are often used in tandem with additional materials that envelope the cells. The combination of cells and usually biopolymer gels are defined as a bio-ink. They must meet certain characteristics, including such as rheological, mechanical, biofunctional and biocompatibility properties, among others. Using bio-inks provides a high reproducibility and precise control over the fabricated constructs in an automated manner. These inks are considered as one of the most advanced tools for tissue engineering and regenerative medicine (TERM).

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.

3D printing filament is the thermoplastic feedstock for fused deposition modeling 3D printers. There are many types of filament available with different properties.

Material extrusion-based additive manufacturing (EAM) represents one of the seven categories of 3d printing processes, defined by the ISO international standard 17296-2. While it is mostly used for plastics, under the name of FDM or FFF, it can also be used for metals and ceramics. In this AM process category, the feedstock materials are mixtures of a polymeric binder and a fine grain solid powder of metal or ceramic materials. Similar type of feedstock is also used in the Metal Injection Molding (MIM) and in the Ceramic Injection Molding (CIM) processes. The extruder pushes the material towards a heated nozzle thanks to

The term preceramic polymer refers to one of various polymeric compounds, which through pyrolysis under appropriate conditions are converted to ceramic compounds, having high thermal and chemical stability. Ceramics resulting from the pyrolysis of preceramic polymers are known as polymer derived ceramics, or PDCs. Polymer derived ceramics are most often silicon based and include silicon carbide, silicon oxycarbide, silicon nitride and silicon oxynitride. Such PDCs are most commonly amorphous, lacking long-range crystalline order.

Polymer derived ceramics (PDCs) are ceramic materials formed by the pyrolysis of preceramic polymers, usually under inert atmosphere.

Cold spray additive manufacturing (CSAM) is a particular application of cold spraying, able to fabricate freestanding parts or to build features on existing components. During the process, fine powder particles are accelerated in a high-velocity compressed gas stream, and upon the impact on a substrate or backing plate, deform and bond together creating a layer. Moving the nozzle over a substrate repeatedly, a deposit is building up layer-by-layer, to form a part or component. If an industrial robot or computer controlled manipulator controls the spray gun movements, complex shapes can be created. To achieve 3D shape, there are two different approaches. First to fix the substrate and move the cold spray gun/nozzle using a robotic arm, the second one is to move the substrate with a robotic arm, and keep the spray-gun nozzle fixed. There is also a possibility to combine these two approaches either using two robotic arms or other manipulators. The process always requires a substrate and uses only powder as raw material.

Multi-material 3D printing is the additive manufacturing procedure of using multiple materials at the same time to fabricate an object. Similar to single material additive manufacturing it can be realised through methods such as FFF, SLA and Inkjet 3D printing. By expanding the design space to different materials, it establishes the possibilities of creating 3D printed objects of different color or with different material properties like elasticity or solubility. The first multi-material 3D printer Fab@Home became publicly available in 2006. The concept was quickly adopted by the industry followed by many consumer ready multi-material 3D printers.

Markforged is an American public additive manufacturing company that designs, develops, and manufactures The Digital Forge — an industrial platform of 3D printers, software and materials that enables manufacturers to print parts at the point-of-need. The company is headquartered in Waltham, Massachusetts, in the Greater Boston Area. Markforged was founded by Gregory Mark and the chief technology officer (CTO) David Benhaim in 2013. It produced the first 3D printers capable of printing continuous carbon fiber reinforcement and utilizes a cloud architecture.

The reinforcement of 3D printed concrete is a mechanism where the ductility and tensile strength of printed concrete are improved using various reinforcing techniques, including reinforcing bars, meshes, fibers, or cables. The reinforcement of 3D printed concrete is important for the large-scale use of the new technology, like in the case of ordinary concrete. With a multitude of additive manufacturing application in the concrete construction industry—specifically the use of additively constructed concrete in the manufacture of structural concrete elements—the reinforcement and anchorage technologies vary significantly. Even for non-structural elements, the use of non-structural reinforcement such as fiber reinforcement is not uncommon. The lack of formwork in most 3D printed concrete makes the installation of reinforcement complicated. Early phases of research in concrete 3D printing primarily focused on developing the material technologies of the cementitious/concrete mixes. These causes combined with the non-existence of codal provisions on reinforcement and anchorage for printed elements speak for the limited awareness and the usage of the various reinforcement techniques in additive manufacturing. The material extrusion-based printing of concrete is currently favorable both in terms of availability of technology and of the cost-effectiveness. Therefore, most of the reinforcement techniques developed or currently under development are suitable to the extrusion-based 3D printing technology.

3D concrete printing, or simply concrete printing, refers to digital fabrication processes for cementitious materials based on one of several different 3D printing technologies. 3D printed concrete eliminates the need for formwork, reducing material waste and allowing for greater geometric freedom in complex structures. With recent developments in mix design and 3D printing technology over the last decade, 3D concrete printing has grown exponentially since its emergence in the 1990s. Architectural and structural applications of 3D-printed concrete include the production of building blocks, building modules, street furniture, pedestrian bridges, and low-rise residential structures.

Bioprinting drug delivery is a method of using the three-dimensional printing of biomaterials through an additive manufacturing technique to develop drug delivery vehicles that are biocompatible tissue-specific hydrogels or implantable devices. 3D bioprinting uses printed cells and biological molecules to manufacture tissues, organs, or biological materials in a scaffold-free manner that mimics living human tissue to provide localized and tissue-specific drug delivery, allowing for targeted disease treatments with scalable and complex geometry.

3D drug printing or 3D printing of pharmaceuticals is a technology that uses three-dimensional printing techniques to create customized pharmaceuticals, such as 3D printed tablets. It allows for precise control over the composition and dosage of drugs, enabling the production of personalized medicine tailored to an individual's specific needs, such as age, weight, and medical condition. This approach can be used to improve the effectiveness of drug therapies and to reduce side effects.