A sewing machine is a machine used to sew fabric and materials together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies. Since the invention of the first sewing machine, generally considered to have been the work of Englishman Thomas Saint in 1790, the sewing machine has greatly improved the efficiency and productivity of the clothing industry.

Appliqué is ornamental needlework in which pieces or patches of fabric in different shapes and patterns are sewn or stuck onto a larger piece to form a picture or pattern. It is commonly used as decoration, especially on garments. The technique is accomplished either by hand stitching or machine. Appliqué is commonly practised with textiles, but the term may be applied to similar techniques used on different materials. In the context of ceramics, for example, an appliqué is a separate piece of clay added to the primary work, generally for the purpose of decoration.

Sewing is the craft of fastening or attaching objects using stitches made with a sewing needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic era. Before the invention of spinning yarn or weaving fabric, archaeologists believe Stone Age people across Europe and Asia sewed fur and leather clothing using bone, antler or ivory sewing-needles and "thread" made of various animal body parts including sinew, catgut, and veins.

A lockstitch is the most common mechanical stitch made by a sewing machine. The term "single needle stitching", often found on dress shirt labels, refers to lockstitch.

A hem in sewing is a garment finishing method, where the edge of a piece of cloth is folded and sewn to prevent unravelling of the fabric and to adjust the length of the piece in garments, such as at the end of the sleeve or the bottom of the garment.

An overlock is a kind of stitch that sews over the edge of one or two pieces of cloth for edging, hemming, or seaming. Usually an overlock sewing machine will cut the edges of the cloth as they are fed through, though some are made without cutters. The inclusion of automated cutters allows overlock machines to create finished seams easily and quickly. An overlock sewing machine differs from a lockstitch sewing machine in that it uses loopers fed by multiple thread cones rather than a bobbin. Loopers serve to create thread loops that pass from the needle thread to the edges of the fabric so that the edges of the fabric are contained within the seam.

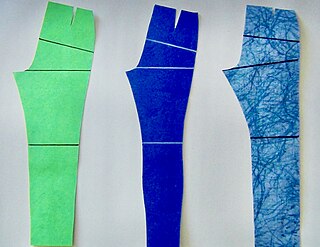

In sewing and fashion design, a pattern is the template from which the parts of a garment are traced onto woven or knitted fabrics before being cut out and assembled. Patterns are usually made of paper, and are sometimes made of sturdier materials like paperboard or cardboard if they need to be more robust to withstand repeated use. The process of making or cutting patterns is sometimes compounded to the one-word Patternmaking, but it can also be written pattern(-)making or pattern cutting.

Bias tape or bias binding is a narrow strip of fabric, typically plain weave, cut on the bias. As the weave of fabric is at a 45 degree angle, the resulting fabric strip is stretchier than a strip cut on the grain. The strip also has a better drape, and conforms to curves better than fabric cut on the grain.

A buttonhole is a reinforced hole in fabric that a button can pass through, allowing one piece of fabric to be secured to another. The raw edges of a buttonhole are usually finished with stitching. This may be done either by hand or by a sewing machine. Some forms of button, such as a frog, use a loop of cloth or rope instead of a buttonhole.

In sewing, to tack or baste is to sew quick, temporary stitches that will later be removed. Tacking is used for a variety of reasons, such as holding a seam in place until it is sewn properly, or transferring pattern markings onto the garment. Tacking is typically sewn using a specialised tacking thread, which may snap easily in order for it to be easily removed from the garment when necessary.

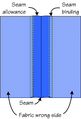

Seam allowance is the area between the fabric edge and the stitching line on two pieces of material being sewn together. Seam allowances can range from 1⁄4 inch (6.4 mm) wide to as much as several inches. Commercial patterns for home sewers have seam allowances ranging from 1⁄4 to 5⁄8 inch.

A pleat is a type of fold formed by doubling fabric back upon itself and securing it in place. It is commonly used in clothing and upholstery to gather a wide piece of fabric to a narrower circumference.

Gathering turns the edge of a piece of fabric into a bunch of small folds that are held together by a thread close to the edge. Gathering makes the fabric shorter where it is stitched. The whole of the fabric flares out into irregular, rolling folds beyond the gathered stitching. Gathering can be done by hand, with a machine, automatically, with elastic, or through channels.

Princess seams are long curved seams sewn into women's blouses or shirts to add shaping or a tailored fit to closely follow a woman's shape. They are a dart variation that is sewn into the front or back of a shirt that extends from the waist up to the shoulder seam or armscye. Princess seams are distinct from darts in that they form a continuous line and are a full seam. Darts, on the other hand, are folds sewn into the clothing to shape the resultant garment.

Darts are folds sewn into fabric to take in ease and provide shape to a garment, especially for a woman's bust. They are used frequently in all sorts of clothing to tailor the garment to the wearer's shape, or to make an innovative shape in the garment. Fabric may be thought of as flat, and a dart has the effect of removing a wedge shaped piece and pulling the edges of that wedge together to create a shallow cone. This effect can be seen quite easily with a paper pattern by pulling together the edges of a dart intake as it would be sewn. Since fabric is generally more flexible than paper, the fabric will shift around the apex of the cone and form a softer, but still curved, shape. In a garment, a dart ends in a point at a full area of the body.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

In sewing and tailoring, a lining is an inner layer of fabric, fur, or other material inserted into clothing, hats, luggage, curtains, handbags and similar items.

In sewing and tailoring, facing is a small piece of fabric, separate or a part of the garment fabric itself, used to finish the fabric edges. This is distinguished from hemming which simply folds the edge over; facing is a more substantial layer of additional fabric added to the edges of the garment. The facing adds addition support, strength and prevents stretching. Facing makes a garment look professionally finished with the seams well hidden inside the folds of the facing. Facing is mostly used to finish the edges in necklines, armholes, hems and openings. They are also used widely in all other sewing like quilts and home decor items like curtain hems.

A coverstitch is formed by two or more needles which add straight stitches to one side of the fabric and a looper thread on the opposite side of the fabric that zig-zags between the straight stitches. A coverstitch results in parallel lines of straight stitches on one side of the fabric and an overcast stitch on the reverse side. It is widely used in garment construction, particularly for attaching trims and flat seaming where the raw edges can be finished in the same operation as forming the seam.