A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis.

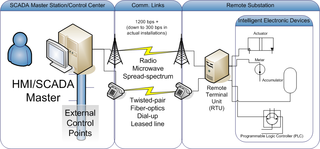

SCADA is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery.

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision.

A control system manages, commands, directs, or regulates the behavior of other devices or systems using control loops. It can range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial control systems which are used for controlling processes or machines. The control systems are designed via control engineering process.

A digital video recorder (DVR), also referred to as a personal video recorder (PVR) particularly in Canada and British English, is an electronic device that records video in a digital format to a disk drive, USB flash drive, SD memory card, SSD or other local or networked mass storage device. The term includes set-top boxes (STB) with direct to disk recording, portable media players and TV gateways with recording capability, and digital camcorders. Personal computers are often connected to video capture devices and used as DVRs; in such cases the application software used to record video is an integral part of the DVR. Many DVRs are classified as consumer electronic devices. Similar small devices with built-in displays and SSD support may be used for professional film or video production, as these recorders often do not have the limitations that built-in recorders in cameras have, offering wider codec support, the removal of recording time limitations and higher bitrates.

A remote terminal unit (RTU) is a microprocessor-controlled electronic device that interfaces objects in the physical world to a distributed control system or SCADA system by transmitting telemetry data to a master system, and by using messages from the master supervisory system to control connected objects. Other terms that may be used for RTU are remote telemetry unit and remote telecontrol unit.

Modbus or MODBUS is a client/server data communications protocol in the application layer. It was originally published by Modicon in 1979 for use with its programmable logic controllers (PLCs). Modbus has become a de facto standard communication protocol for communication between industrial electronic devices in a wide range of buses and network.

Open Platform Communications (OPC) is a series of standards and specifications for industrial telecommunication. They are based on Object Linking and Embedding (OLE) for process control. An industrial automation task force developed the original standard in 1996 under the name OLE for Process Control. OPC specifies the communication of real-time plant data between control devices from different manufacturers.

A data logger is an electronic device that records data over time or about location either with a built-in instrument or sensor or via external instruments and sensors. Increasingly, but not entirely, they are based on a digital processor, and called digital data loggers (DDL). They generally are small, battery-powered, portable, and equipped with a microprocessor, internal memory for data storage, and sensors. Some data loggers interface with a personal computer and use software to activate the data logger and view and analyze the collected data, while others have a local interface device and can be used as a stand-alone device.

Power-system automation is the act of automatically controlling the power system via instrumentation and control devices. Substation automation refers to using data from Intelligent electronic devices (IED), control and automation capabilities within the substation, and control commands from remote users to control power-system devices.

Distributed Network Protocol 3 (DNP3) is a set of communications protocols used between components in process automation systems. Its main use is in utilities such as electric and water companies. Usage in other industries is not common. It was developed for communications between various types of data acquisition and control equipment. It plays a crucial role in SCADA systems, where it is used by SCADA Master Stations, Remote Terminal Units (RTUs), and Intelligent Electronic Devices (IEDs). It is primarily used for communications between a master station and RTUs or IEDs. ICCP, the Inter-Control Center Communications Protocol, is used for inter-master station communications. Competing standards include the older Modbus protocol and the newer IEC 61850 protocol.

A phasor measurement unit (PMU) is a device used to estimate the magnitude and phase angle of an electrical phasor quantity in the electricity grid using a common time source for synchronization. Time synchronization is usually provided by GPS or IEEE 1588 Precision Time Protocol, which allows synchronized real-time measurements of multiple remote points on the grid. PMUs are capable of capturing samples from a waveform in quick succession and reconstructing the phasor quantity, made up of an angle measurement and a magnitude measurement. The resulting measurement is known as a synchrophasor. These time synchronized measurements are important because if the grid’s supply and demand are not perfectly matched, frequency imbalances can cause stress on the grid, which is a potential cause for power outages.

In Electrical Power Systems and Industrial Automation, ANSI Device Numbers can be used to identify equipment and devices in a system such as relays, circuit breakers, or instruments. The device numbers are enumerated in ANSI/IEEE Standard C37.2 "Standard for Electrical Power System Device Function Numbers, Acronyms, and Contact Designations".

An industrial control system (ICS) is an electronic control system and associated instrumentation used for industrial process control. Control systems can range in size from a few modular panel-mounted controllers to large interconnected and interactive distributed control systems (DCSs) with many thousands of field connections. Control systems receive data from remote sensors measuring process variables (PVs), compare the collected data with desired setpoints (SPs), and derive command functions that are used to control a process through the final control elements (FCEs), such as control valves.

The following outline is provided as an overview of and topical guide to automation:

IEC 60870 part 6 in electrical engineering and power system automation, is one of the IEC 60870 set of standards which define systems used for telecontrol in electrical engineering and power system automation applications. The IEC Technical Committee 57 have developed part 6 to provide a communication profile for sending basic telecontrol messages between two systems which is compatible with ISO standards and ITU-T recommendations.

IEC 60870 part 5 is one of the IEC 60870 set of standards which define systems used for telecontrol in electrical engineering and power system automation applications. Part 5 provides a communication profile for sending basic telecontrol messages between two systems, which uses permanent directly connected data circuits between the systems. The IEC Technical Committee 57 have developed a protocol standard for telecontrol, teleprotection, and associated telecommunications for electric power systems. The result of this work is IEC 60870-5. Five documents specify the base IEC 60870-5:

Ignition is an Integrated Software Platform for SCADA systems released by Inductive Automation in January 2010. It is based on a SQL Database-centric architecture. Ignition features cross-platform, web-based deployment through Java Web Start technology. The Ignition platform has three main components: the Ignition Gateway, the Designer, and the runtime clients. Independent modules provide separate functionality in any or all of the platform components. Ignition SCADA modules provide features such as: Real-Time Status Control, Alarming, Reporting, Data Acquisition, Scripting, Scheduling, MES, and Mobile support.

PLC technicians design, program, repair, and maintain programmable logic controller (PLC) systems used within manufacturing and service industries ranging from industrial packaging to commercial car washes and traffic lights.

Trihedral Engineering Limited (Trihedral) is a Bedford, Nova Scotia, Canada–based creator of industrial automation software. The VTScada SCADA platform is the company's main product.