A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle.

ISO 3166-1 alpha-2 codes are two-letter country codes defined in ISO 3166-1, part of the ISO 3166 standard published by the International Organization for Standardization (ISO), to represent countries, dependent territories, and special areas of geographical interest. They are the most widely used of the country codes published by ISO, and are used most prominently for the Internet's country code top-level domains. They are also used as country identifiers extending the postal code when appropriate within the international postal system for paper mail, and have replaced the previous one consisting one-letter codes. They were first included as part of the ISO 3166 standard in its first edition in 1974.

Rebar, known when massed as reinforcing steel or steel reinforcement, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging.

Reynolds 531 is a brand name, registered to Reynolds Technology of Birmingham in the United Kingdom, for a manganese–molybdenum, medium-carbon steel tubing that was used in many quality applications, including race car chassis, aircraft components and, most famously, bicycle frame tubing. It is one of a number of tubing types developed by Reynolds.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

The IP code or ingress protection code indicates how well a device is protected against water and dust. It is defined by the International Electrotechnical Commission (IEC) under the international standard IEC 60529 which classifies and provides a guideline to the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. It is published in the European Union by the European Committee for Electrotechnical Standardization (CENELEC) as EN 60529.

Marine grade stainless alloys typically contain molybdenum to resist the corrosive effects of NaCl or salt in seawater. Concentrations of salt in seawater can vary, and splash zones can cause concentrations to increase dramatically from the spray and evaporation.

The unified numbering system (UNS) is an alloy designation system widely accepted in North America. Each UNS number relates to a specific metal or alloy and defines its specific chemical composition, or in some cases a specific mechanical or physical property. A UNS number alone does not constitute a full material specification because it establishes no requirements for material properties, heat treatment, form, or quality.

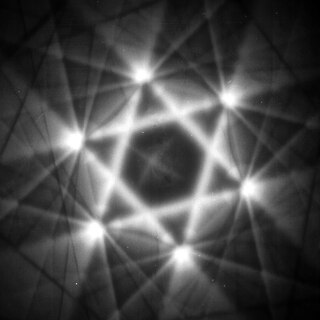

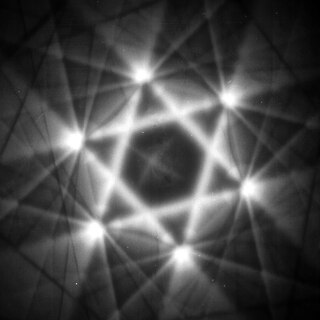

Austenitic stainless steel is one of the five classes of stainless steel by crystalline structure. Its primary crystalline structure is austenite and it prevents steels from being hardenable by heat treatment and makes them essentially non-magnetic. This structure is achieved by adding enough austenite-stabilizing elements such as nickel, manganese and nitrogen. The Incoloy family of alloys belong to the category of super austenitic stainless steels.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

The SAE steel grades system is a standard alloy numbering system for steel grades maintained by SAE International.

In drilling technology, casing string is a long section of connected oilfield pipe that is lowered into a wellbore and cemented. The purpose of the casing pipe is as follows:

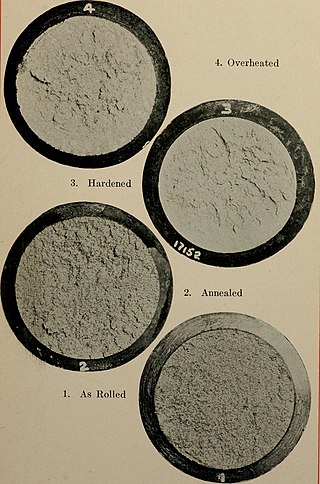

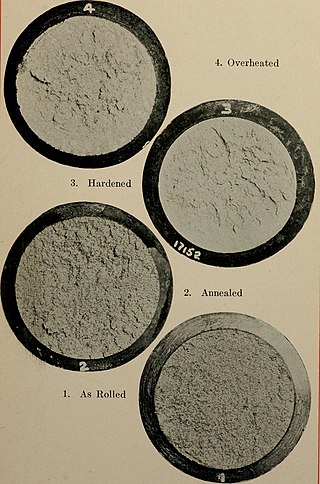

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

SAE 304 stainless steel is the most common stainless steel. It is an alloy of iron, carbon, chromium and nickel. It is an austenitic stainless steel, and is therefore not magnetic. It is less electrically and thermally conductive than carbon steel. It has a higher corrosion resistance than regular steel and is widely used because of the ease in which it is formed into various shapes.

A gas cabinet is a metallic enclosure which is used to provide local exhaust ventilation system for virtually all of the gases used or generated in the semiconductor, solar, MEMS, NANO, solar PV, manufacturing and other advanced technologies.

X46Cr13 is the European Norm name for a common martensitic stainless steel with the numeric name 1.4034. It is equivalent to American Iron and Steel Institute standard 420C. It has the highest carbon content of the SAE 420 series.