Equations

The equations for stripping ratio are,

for coal:

for metal:

where volume is typically expressed as m3 or yd3 and weight is typically expressed as tonne or ton.

In surface mining, stripping ratio or strip ratio refers to the amount of waste (or overburden) that must be removed to release a given ore quantity. [1] [2] It is a number or ratio that express how much waste is mined per unit of ore. The units of a stripping ratio can vary between mine types. For example, in coal mining the stripping ratio is commonly referred to as volume/weight. [3] , whereas in metal mining, stripping ratio is unitless and is expressed as weight/weight. [2] A stripping ratio can be expressed as a ratio or as a number.

The equations for stripping ratio are,

for coal:

for metal:

where volume is typically expressed as m3 or yd3 and weight is typically expressed as tonne or ton.

It is common for the stripping ratio to be used as an indicator of economic value for an open pit mine. [1] This is because removal of waste is a cost to the mine whereas mining ore leads to revenue. A stripping ratio is commonly used as a quick method to evaluate a mine’s or a design’s value. High stripping ratios are not desired because they are indicating that large amounts of waste must be moved to access ore.

Mining is the extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. The ore must be a rock or mineral that contains valuable constituent, can be extracted or mined and sold for profit. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water.

Ore is natural rock or sediment that contains one or more valuable minerals concentrated above background levels, typically containing metals, that can be mined, treated and sold at a profit. The grade of ore refers to the concentration of the desired material it contains. The value of the metals or minerals a rock contains must be weighed against the cost of extraction to determine whether it is of sufficiently high grade to be worth mining and is therefore considered an ore. A complex ore is one containing more than one valuable mineral.

Relative density, also called specific gravity, is a dimensionless quantity defined as the ratio of the density of a substance to the density of a given reference material. Specific gravity for liquids is nearly always measured with respect to water at its densest ; for gases, the reference is air at room temperature. The term "relative density" is preferred in SI, whereas the term "specific gravity" is gradually being abandoned.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe

3O

4, 72.4% Fe), hematite (Fe

2O

3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H2O), 55% Fe), or siderite (FeCO3, 48.2% Fe).

Coal mining is the process of extracting coal from the ground or from a mine. Coal is valued for its energy content and since the 1880s has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United Kingdom and South Africa, a coal mine and its structures are a colliery, a coal mine is called a "pit", and above-ground mining structures are referred to as a "pit head". In Australia, "colliery" generally refers to an underground coal mine.

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique that extracts rock or minerals from the earth using a pit, sometimes known as a borrow pit.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Mining in the engineering discipline is the extraction of minerals from the ground. Mining engineering is associated with many other disciplines, such as mineral processing, exploration, excavation, geology, metallurgy, geotechnical engineering and surveying. A mining engineer may manage any phase of mining operations, from exploration and discovery of the mineral resources, through feasibility study, mine design, development of plans, production and operations to mine closure.

In mining, overburden is the material that lies above an area that lends itself to economical exploitation, such as the rock, soil, and ecosystem that lies above a coal seam or ore body. Overburden is distinct from tailings, the material that remains after economically valuable components have been extracted from the generally finely milled ore. Overburden is removed during surface mining, but is typically not contaminated with toxic components. Overburden may also be used to restore an exhausted mining site during reclamation.

In mining, gangue is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body that are displaced during mining without being processed, and from tailings, which is rock already stripped of valuable minerals.

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century. It has been described as "the single most important operation used for the recovery and upgrading of sulfide ores". The development of froth flotation has improved the recovery of valuable minerals, such as copper- and lead-bearing minerals. Along with mechanized mining, it has allowed the economic recovery of valuable metals from much lower-grade ore than previously.

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit are removed, in contrast to underground mining, in which the overlying rock is left in place, and the mineral is removed through shafts or tunnels.

In thermodynamics, the thermal efficiency is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

The following outline is provided as an overview of and topical guide to mining:

Fred Chester Bond was an American mining engineer. A graduate of the Colorado School of Mines, he worked in the mining equipment and ore milling equipment business of Allis-Chalmers from 1930 to 1964.

Cominco Resources is a private company which is developing the US$2billion Hinda phosphate project located in The Republic of the Congo. Through its subsidiary it owns 100% of the Hinda Phosphate Project, which comprises the Hinda Permit, and the Kolatchikanou Permit. The Hinda project is the world's largest undeveloped phosphate deposit with a JORC Mineral Resource of 678 Mt and a Minable Ore Reserve of 405 Mt, sufficient for over 24 years of production. Cominco Resources was merged with Kropz in December 2018 and listed on the AIM market.

A circle-throw vibrating machine is a screening machine employed in processes involving particle separation. In particle processes screening refers to separation of larger from smaller particles in a given feed, using only the materials' physical properties. Circle throw machines have simple structure with high screening efficiency and volume. However it has limitations on the types of feed that can be processed smoothly. Some characteristics of circle-throw machines, such as frequency, vibration amplitude and angle of incline deck also affect output.

Mineral resource estimation is used to determine and define the ore tonnage and grade of a geological deposit, from the developed block model. There are different estimation methods used for different scenarios dependent upon the ore boundaries, geological deposit geometry, grade variability and the amount of time and money available. A typical resource estimation involves the construction of a geological and resource model with data from various sources. Depending on the nature of the information and whether the data is hard copy or computerized, the principal steps of computer resource estimation are:

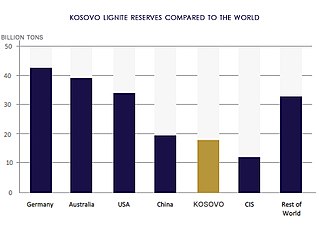

Lignite coal in Kosovo is and will continue to be an important local energy source due to its high reserves. Kosovo is very rich in lignite and accounts around 90% of Kosovo's electricity production. The nation has the 5th largest lignite reserves in the world and the 3rd in Europe. The lignite is distributed across the Kosovo, Dukagjin and Drenica Basins, although mining has so far been restricted to the Kosovo Basin. The lignite is of high quality for the generation of electricity and compares well with the lignite resources of neighbouring countries on a range of parameters. Kosovo's lignite varies in net calorific value from 6.28-9.21 MJ/kg, averaging 7.8 MJ/kg. The deposits can be up to 100 m thick, but average 40 m, and possess an average strip ratio of 1.7:1.

{{cite book}}: CS1 maint: multiple names: authors list (link) CS1 maint: numeric names: authors list (link){{cite book}}: CS1 maint: others (link)