Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high-quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic table: carbon is above it; and germanium, tin, lead, and flerovium are below it. It is relatively unreactive. Silicon (Si) element is a significant element that is essential for several physiological and metabolic processes in plants. Si is widely regarded as the predominant semiconductor material due to its versatile applications in various electrical devices such as transistors, solar cells, integrated circuits, and others. These may be due to its significant band gap, expansive optical transmission range, extensive absorption spectrum, surface roughening, and effective anti-reflection coating.

In chemistry, a silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula [SiO(4-2x)−

4−x]

n, where 0 ≤ x < 2. The family includes orthosilicate SiO4−4, metasilicate SiO2−3, and pyrosilicate Si2O6−7. The name is also used for any salt of such anions, such as sodium metasilicate; or any ester containing the corresponding chemical group, such as tetramethyl orthosilicate. The name "silicate" is sometimes extended to any anions containing silicon, even if they do not fit the general formula or contain other atoms besides oxygen; such as hexafluorosilicate [SiF6]2−.Most commonly, silicates are encountered as silicate minerals.

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula SiO2, commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is abundant as it comprises several minerals and synthetic products. All forms are white or colorless, although impure samples can be colored.

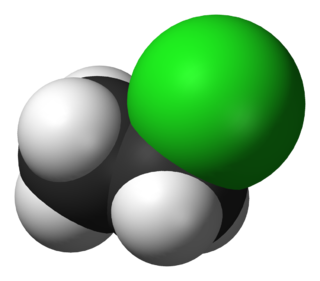

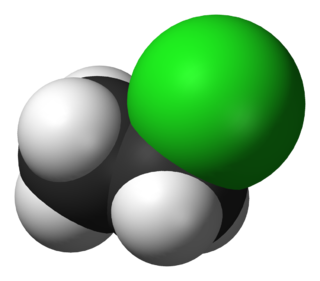

Chloroethane, commonly known as ethyl chloride, is a chemical compound with chemical formula CH3CH2Cl, once widely used in producing tetraethyllead, a gasoline additive. It is a colorless, flammable gas or refrigerated liquid with a faintly sweet odor.

Calcium silicate is the chemical compound Ca2SiO4, also known as calcium orthosilicate and is sometimes formulated as 2CaO·SiO2. It is also referred to by the shortened trade name Cal-Sil or Calsil. It occurs naturally as the mineral larnite.

Methyl ethyl ketone peroxide (MEKP) is an organic peroxide with the formula [(CH3)(C2H5)C(O2H)]2O2. MEKP is a colorless oily liquid. It is widely used in vulcanization (crosslinking) of polymers.

Silicate minerals are rock-forming minerals made up of silicate groups. They are the largest and most important class of minerals and make up approximately 90 percent of Earth's crust.

A molecular sieve is a material with pores of uniform size. These pore diameters are similar in size to small molecules, and thus large molecules cannot enter or be adsorbed, while smaller molecules can. As a mixture of molecules migrates through the stationary bed of porous, semi-solid substance referred to as a sieve, the components of the highest molecular weight leave the bed first, followed by successively smaller molecules. Some molecular sieves are used in size-exclusion chromatography, a separation technique that sorts molecules based on their size. Another important use is as a desiccant. Most of molecular sieves are aluminosilicate zeolites with Si/Al molar ratio less than 2, but there are also examples of activated charcoal and silica gel.

In materials science, the sol–gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon (Si) and titanium (Ti). The process involves conversion of monomers into a colloidal solution (sol) that acts as the precursor for an integrated network of either discrete particles or network polymers. Typical precursors are metal alkoxides. Sol–gel process is used to produce ceramic nanoparticles.

1,1-Dichloroethylene, commonly called vinylidene chloride or 1,1-DCE, is an organochloride with the molecular formula CHClCl2CH3. It is a colorless liquid with a sharp odor. Like most chlorocarbons, it is poorly soluble in water but soluble in organic solvents. 1,1-DCE was the precursor to the original clingwrap, Saran, for food, but this application has been phased out.

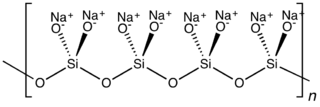

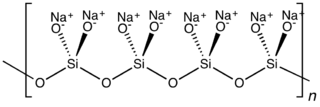

Sodium metasilicate is the chemical substance with formula Na

2SiO

3, which is the main component of commercial sodium silicate solutions. It is an ionic compound consisting of sodium cations Na+

and the polymeric metasilicate anions [–SiO2−

3–]n. It is a colorless crystalline hygroscopic and deliquescent solid, soluble in water but not in alcohols.

Silicon compounds are compounds containing the element silicon (Si). As a carbon group element, silicon often forms compounds in the +4 oxidation state, though many unusual compounds have been discovered that differ from expectations based on its valence electrons, including the silicides and some silanes. Metal silicides, silicon halides, and similar inorganic compounds can be prepared by directly reacting elemental silicon or silicon dioxide with stable metals or with halogens. Silanes, compounds of silicon and hydrogen, are often used as strong reducing agents, and can be prepared from aluminum–silicon alloys and hydrochloric acid.

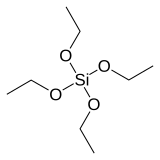

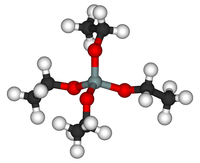

Tetramethyl orthosilicate (TMOS) is the chemical compound with the formula Si(OCH3)4. This molecule consists of four methoxy groups bonded to a silicon atom. The basic properties are similar to the more popular tetraethyl orthosilicate, which is usually preferred because the product of hydrolysis, ethanol, is less toxic than methanol.

Colloidal silicas are suspensions of fine amorphous, nonporous, and typically spherical silica particles in a liquid phase. It may be produced by Stöber process from Tetraethyl orthosilicate (TEOS).

Hydrophobic silica is a form of silicon dioxide that has hydrophobic groups chemically bonded to the surface. The hydrophobic groups are normally alkyl or polydimethylsiloxane chains. Hydrophobic silica can be processed in different ways; such as fumed silica, precipitated silica, and aerosol assisted self assembly, all existing in the form of nanoparticles.

The Stöber process is a chemical process used to prepare silica particles of controllable and uniform size for applications in materials science. It was pioneering when it was reported by Werner Stöber and his team in 1968, and remains today the most widely used wet chemistry synthetic approach to silica nanoparticles. It is an example of a sol-gel process wherein a molecular precursor is first reacted with water in an alcoholic solution, the resulting molecules then joining together to build larger structures. The reaction produces silica particles with diameters ranging from 50 to 2000 nm, depending on conditions. The process has been actively researched since its discovery, including efforts to understand its kinetics and mechanism – a particle aggregation model was found to be a better fit for the experimental data than the initially hypothesized LaMer model. The newly acquired understanding has enabled researchers to exert a high degree of control over particle size and distribution and to fine-tune the physical properties of the resulting material in order to suit intended applications.

In chemistry, orthosilicate is the anion SiO4−

4, or any of its salts and esters. It is one of the silicate anions. It is occasionally called the silicon tetroxide anion or group.

Khimprom Novocheboksarsk is a chemicals-producing company based in Novocheboksarsk, Russia. It is part of Orgsintez Group (Renova).

In chemistry, a silicic acid is any chemical compound containing the element silicon attached to oxide and hydroxyl groups, with the general formula [H2xSiOx+2]n or, equivalently, [SiOx(OH)4−2x]n. Orthosilicic acid is a representative example. Silicic acids are rarely observed in isolation, but are thought to exist in aqueous solutions, including seawater, and play a role in biomineralization. They are typically colorless weak acids that are sparingly soluble in water. Like the silicate anions, which are their better known conjugate bases, silicic acids are proposed to be oligomeric or polymeric. No simple silicic acid has ever been identified, since these species are primarily of theoretical interest.