In organic chemistry, isocyanate is the functional group with the formula R−N=C=O. Organic compounds that contain an isocyanate group are referred to as isocyanates. An organic compound with two isocyanate groups is known as a diisocyanate. Diisocyanates are manufactured for the production of polyurethanes, a class of polymers.

The American Conference of Governmental Industrial Hygienists (ACGIH) is a professional association of industrial hygienists and practitioners of related professions, with headquarters in Cincinnati, Ohio. One of its goals is to advance worker protection by providing timely, objective, scientific information to occupational and environmental health professionals.

Occupational hygiene is the anticipation, recognition, evaluation, control, and confirmation (ARECC) of protection from risks associated with exposures to hazards in, or arising from, the workplace that may result in injury, illness, impairment, or affect the well-being of workers and members of the community. These hazards or stressors are typically divided into the categories biological, chemical, physical, ergonomic and psychosocial. The risk of a health effect from a given stressor is a function of the hazard multiplied by the exposure to the individual or group. For chemicals, the hazard can be understood by the dose response profile most often based on toxicological studies or models. Occupational hygienists work closely with toxicologists for understanding chemical hazards, physicists for physical hazards, and physicians and microbiologists for biological hazards. Environmental and occupational hygienists are considered experts in exposure science and exposure risk management. Depending on an individual's type of job, a hygienist will apply their exposure science expertise for the protection of workers, consumers and/or communities.

The permissible exposure limit is a legal limit in the United States for exposure of an employee to a chemical substance or physical agent such as high level noise. Permissible exposure limits were established by the Occupational Safety and Health Administration (OSHA). Most of OSHA's PELs were issued shortly after adoption of the Occupational Safety and Health (OSH) Act in 1970.

Acute toxicity describes the adverse effects of a substance that result either from a single exposure or from multiple exposures in a short period of time. To be described as acute toxicity, the adverse effects should occur within 14 days of the administration of the substance.

Chloroprene (IUPAC name 2-chlorobuta-1,3-diene) is a chemical compound with the molecular formula CH2=CCl−CH=CH2. Chloroprene is a colorless volatile liquid, almost exclusively used as a monomer for the production of the polymer polychloroprene, better known as neoprene, a type of synthetic rubber.

Exposure assessment is a branch of environmental science and occupational hygiene that focuses on the processes that take place at the interface between the environment containing the contaminant of interest and the organism being considered. These are the final steps in the path to release an environmental contaminant, through transport to its effect in a biological system. It tries to measure how much of a contaminant can be absorbed by an exposed target organism, in what form, at what rate and how much of the absorbed amount is actually available to produce a biological effect. Although the same general concepts apply to other organisms, the overwhelming majority of applications of exposure assessment are concerned with human health, making it an important tool in public health.

A recommended exposure limit (REL) is an occupational exposure limit that has been recommended by the United States National Institute for Occupational Safety and Health. The REL is a level that NIOSH believes would be protective of worker safety and health over a working lifetime if used in combination with engineering and work practice controls, exposure and medical monitoring, posting and labeling of hazards, worker training and personal protective equipment. To formulate these recommendations, NIOSH evaluates all known and available medical, biological, engineering, chemical, trade, and other information. Although not legally enforceable limits, RELS are transmitted to the Occupational Safety and Health Administration (OSHA) or the Mine Safety and Health Administration (MSHA) of the U.S. Department of Labor for use in promulgating legal standards.

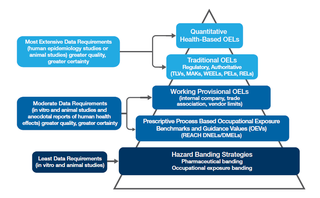

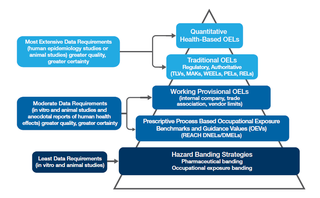

An occupational exposure limit is an upper limit on the acceptable concentration of a hazardous substance in workplace air for a particular material or class of materials. It is typically set by competent national authorities and enforced by legislation to protect occupational safety and health. It is an important tool in risk assessment and in the management of activities involving handling of dangerous substances. There are many dangerous substances for which there are no formal occupational exposure limits. In these cases, hazard banding or control banding strategies can be used to ensure safe handling.

1-Bromopropane (n-propylbromide or nPB) is an organobromine compound with the chemical formula CH3CH2CH2Br. It is a colorless liquid that is used as a solvent. It has a characteristic hydrocarbon odor. Its industrial applications increased dramatically in the 21st century due to the phasing out of chlorofluorocarbons and chloroalkanes such as 1,1,1-Trichloroethane under the Montreal Protocol.

An Exposure Action Value (EAV) or Action Value (AV) is a limit set on occupational exposure to noise where, when those values are exceeded, employers must take steps to monitor the exposure levels. These levels are measured in decibels. The American Occupational Safety and Health Administration (OSHA) set the EAV to 85 dB(A). When the eight-hour time-weighted average (TWA) reaches 85 dB(A), employers are required to administer a continuing, effective hearing conservation program. The program consists of monitoring, employee notification, observation, an audiometric testing program, hearing protectors, training programs, and record-keeping requirements.

A short-term exposure limit (STEL) is the acceptable average exposure over a short period of time, usually 15 minutes as long as the time-weighted average is not exceeded.

The American Industrial Hygiene Association (AIHA) is a 501(c)6 non-profit organization, whose mission is "Creating knowledge to protect worker health." The American Industrial Hygiene Association works to provide information and resources to Industrial Hygienists and Occupational Health professionals.

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

The respiratory protective devices (RPD) can protect workers only if their protective properties are adequate to the conditions in the workplace. Therefore, specialists have developed criteria for the selection of proper, adequate respirators, including the Assigned Protection Factors (APF) - the decrease of the concentration of harmful substances in the inhaled air, which to be provided with timely and proper use of a certified respirator of certain types (design) by taught and trained workers, when the employer performs an effective respiratory protective device programme.

Occupational dust exposure occurs when small particles are generated at the workplace through the disturbance/agitation of rock/mineral, dry grain, timber, fiber, or other material. When these small particles become suspended in the air, they can pose a risk to the health of those who breath in the contaminated air.

Occupational exposure banding, also known as hazard banding, is a process intended to quickly and accurately assign chemicals into specific categories (bands), each corresponding to a range of exposure concentrations designed to protect worker health. These bands are assigned based on a chemical’s toxicological potency and the adverse health effects associated with exposure to the chemical. The output of this process is an occupational exposure band (OEB). Occupational exposure banding has been used by the pharmaceutical sector and by some major chemical companies over the past several decades to establish exposure control limits or ranges for new or existing chemicals that do not have formal OELs. Furthermore, occupational exposure banding has become an important component of the Hierarchy of Occupational Exposure Limits (OELs).

There are unique occupational health issues in the casino industry, many of which are attributed to repetitive tasks and long-term exposures to hazards in the casino environment. Among these issues are cancers resulting from exposure to second-hand tobacco smoke, musculoskeletal injury (MSI) from repetitive motion injuries while running table games over many hours, and health issues associated with shift work. Safety and regulatory agencies in the United States have implemented regulatory measures to address the specific risks associated with workers in the casino industry, and have made efforts to identify additional possible risks to casino workers, including noise-induced hearing loss and heavy metal poisoning from exposure to dust from coins.

Workplace exposure monitoring is the monitoring of substances in a workplace that are chemical or biological hazards. It is performed in the context of workplace exposure assessment and risk assessment. Exposure monitoring analyzes hazardous substances in the air or on surfaces of a workplace, and is complementary to biomonitoring, which instead analyzes toxicants or their effects within workers.