Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

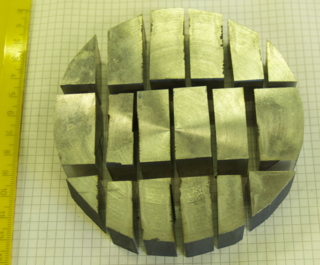

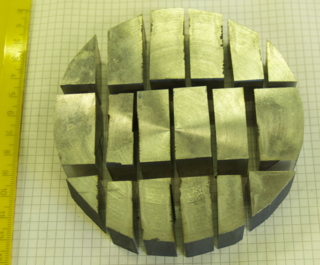

Cupronickel or copper-nickel (CuNi) is an alloy of copper with nickel, usually along with small quantities of other elements added for strength, such as iron and manganese. The copper content typically varies from 60 to 90 percent.

An actuator is a component of a machine that produces force, torque, or displacement, usually in a controlled way, when an electrical, pneumatic or hydraulic input is supplied to it in a system. An actuator converts such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover".

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream. As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function.

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion, making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about 165 °C (300 °F). It is commonly used for the construction of reagent bottles and flasks, as well as lighting, electronics, and cookware.

A plate-fin heat exchanger is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids, most commonly gases. It is often categorized as a compact heat exchanger to emphasize its relatively high heat transfer surface area to volume ratio. The plate-fin heat exchanger is widely used in many industries, including the aerospace industry for its compact size and lightweight properties, as well as in cryogenics where its ability to facilitate heat transfer with small temperature differences is utilized.

A piping and instrumentation diagram is a detailed diagram in the process industry which shows the piping and process equipment together with the instrumentation and control devices.

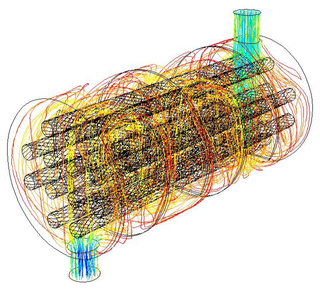

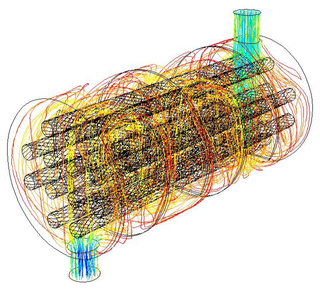

A shell-and-tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

A deaerator is a device that is used for the removal of dissolved gases like oxygen from a liquid.

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water-cooled surface condenser.

Electronic packaging is the design and production of enclosures for electronic devices ranging from individual semiconductor devices up to complete systems such as a mainframe computer. Packaging of an electronic system must consider protection from mechanical damage, cooling, radio frequency noise emission and electrostatic discharge. Product safety standards may dictate particular features of a consumer product, for example, external case temperature or grounding of exposed metal parts. Prototypes and industrial equipment made in small quantities may use standardized commercially available enclosures such as card cages or prefabricated boxes. Mass-market consumer devices may have highly specialized packaging to increase consumer appeal. Electronic packaging is a major discipline within the field of mechanical engineering.

An evaporator is a type of heat exchanger device that facilitates evaporation by utilizing conductive and convective heat transfer to provide the necessary thermal energy for phase transition from liquid to vapor. Within evaporators, a circulating liquid is exposed to an atmospheric or reduced pressure environment, causing it to boil at a lower temperature compared to normal atmospheric boiling.

The dynamic scraped surface heat exchanger (DSSHE) is a type of heat exchanger used to remove or add heat to fluids, mainly foodstuffs, but also other industrial products. They have been designed to address specific problems that impede efficient heat transfer. DSSHEs improve efficiency by removing fouling layers, increasing turbulence in the case of high viscosity flow, and avoiding the generation of crystals and other process by-products. DSSHEs incorporate an internal mechanism which periodically removes the product from the heat transfer wall. The sides are scraped by blades made of a rigid plastic material to prevent damage to the scraped surface.

Baffles are flow-directing or obstructing vanes or panels used to direct a flow of liquid or gas. It is used in some household stoves and in some industrial process vessels (tanks), such as shell and tube heat exchangers, chemical reactors, and static mixers.

The ASME Boiler & Pressure Vessel Code (BPVC) is an American Society of Mechanical Engineers (ASME) standard that regulates the design and construction of boilers and pressure vessels. The document is written and maintained by volunteers chosen for their technical expertise. The ASME works as an accreditation body and entitles independent third parties to inspect and ensure compliance to the BPVC.

ISGEC Heavy Engineering Ltd is an Indian heavy engineering company. Established in 1933 as Saraswati Sugar Syndicate, the company held a revenue of ₹5,477 crore (US$690 million) in 2021 with exports of approximately 91 countries. It was ranked 252 in the ET 2021 listing, and 253 in the Fortune India 500 Listings.

Duplex stainless steels are a family of stainless steels. These are called duplex grades because their metallurgical structure consists of two phases, austenite and ferrite in roughly equal proportions. They are designed to provide better corrosion resistance, particularly chloride stress corrosion and chloride pitting corrosion, and higher strength than standard austenitic stainless steels such as type A2/304 or A4/316. The main differences in composition, when compared with an austenitic stainless steel is that the duplex steels have a higher chromium content, 20–28%; higher molybdenum, up to 5%; lower nickel, up to 9% and 0.05–0.50% nitrogen. Both the low nickel content and the high strength give significant cost benefits. They are therefore used extensively in the offshore oil and gas industry for pipework systems, manifolds, risers, etc. and in the petrochemical industry in the form of pipelines and pressure vessels. In addition to the improved corrosion resistance compared with the 300 series duplex stainless steels also have higher strength. For example, a Type 304 stainless steel has a 0.2% proof strength in the region of 280 MPa (41 ksi), a 22%Cr duplex stainless steel a minimum 0.2% proof strength of some 450 MPa (65 ksi) and a superduplex grade a minimum of 550 MPa (80 ksi).

Heat exchangers are devices that transfer heat to achieve desired heating or cooling. An important design aspect of heat exchanger technology is the selection of appropriate materials to conduct and transfer heat fast and efficiently.