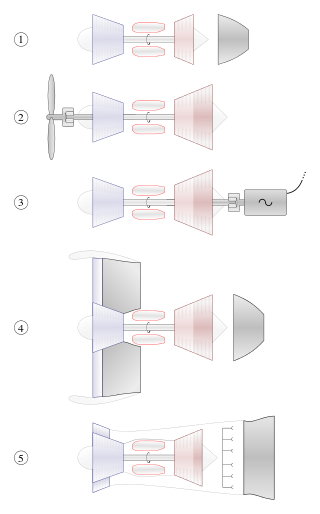

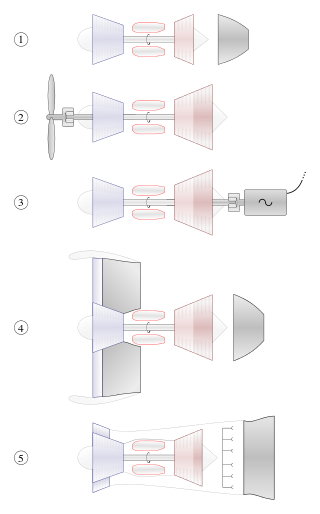

A gas turbine,gas turbine engine, or also known by its old name internal combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

The Brayton cycle is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid. The original Brayton Ready Motor used a piston compressor and piston expander, but modern gas turbine engines and airbreathing jet engines also follow the Brayton cycle. Although the cycle is usually run as an open system, it is conventionally assumed for the purposes of thermodynamic analysis that the exhaust gases are reused in the intake, enabling analysis as a closed system.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant, which is a kind of gas-fired power plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

A fire-tube boiler is a type of boiler invented in 1828 by Mark Seguin, in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

British Rail 18000 was a prototype mainline gas turbine-electric locomotive built for British Railways in 1949 by Brown, Boveri & Cie. An earlier gas-turbine locomotive, 18100, had been ordered from Metropolitan-Vickers by the Great Western Railway but construction was delayed due to World War II; a second, 18000, was thus ordered from Switzerland in 1946. It spent its working life on the Western Region of British Railways, operating express passenger services from Paddington station, London.

A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or natural gas, to produce electricity. Fossil fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical generator. The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine. All plants use the energy extracted from the expansion of a hot gas, either steam or combustion gases. Although different energy conversion methods exist, all thermal power station conversion methods have their efficiency limited by the Carnot efficiency and therefore produce waste heat.

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Economizers, or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) uses are discussed in this article. In simple terms, an economizer is a heat exchanger.

A flue-gas stack, also known as a smoke stack, chimney stack or simply as a stack, is a type of chimney, a vertical pipe, channel or similar structure through, which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power plant's steam-generating boiler, or other large combustion device. Flue gas is usually composed of carbon dioxide (CO2) and water vapor, as well as nitrogen and excess oxygen remaining from the intake combustion air. It also contains a small percentage of pollutants such as particulate matter, carbon monoxide, nitrogen oxides and sulfur oxides. The flue gas stacks are often quite tall, up to 420 metres (1,380 ft), to increase the stack effect and dispersion of pollutants.

A turboexpander, also referred to as a turbo-expander or an expansion turbine, is a centrifugal or axial-flow turbine, through which a high-pressure gas is expanded to produce work that is often used to drive a compressor or generator.

Cottam power station is a decommissioned coal-fired power station. The site extends over 620 acres (250 ha) of mainly arable land and is situated at the eastern edge of Nottinghamshire on the west bank of the River Trent at Cottam near Retford. The larger coal-fired station was decommissioned by EDF Energy in 2019 in line with the UK's goal to meet its zero-coal power generation by 2025. The smaller in-use station is Cottam Development Centre, a combined cycle gas turbine plant commissioned in 1999, with a generating capacity of 440 MW. This plant is owned by Uniper.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

Am 4/6 1101 was the world's first gas turbine-electric locomotive. The locomotive was ordered by the Swiss Federal Railways (SBB-CFF-FFS) from the Swiss Locomotive and Machine Works (SLM) and Brown, Boveri & Cie (BBC) in 1939. The locomotive was delivered in 1941 and was in use on railroads in Switzerland, France and Germany until 1954.

A "Scotch" marine boiler is a design of steam boiler best known for its use on ships.

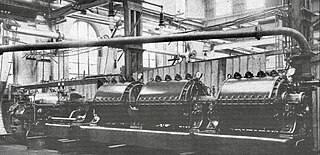

The Armengaud-Lemale gas turbine was an early experimental turbine engine built by the Société Anonyme des Turbomoteurs and exhibited during 1906 in Paris, France. The gas turbine could sustain its own air compression but was too inefficient to produce useful work. The Armengaud-Lemale combustion chamber design was later used successfully in torpedo engines.

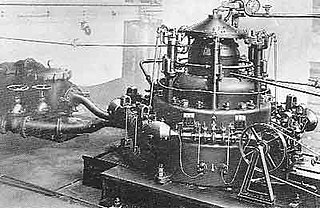

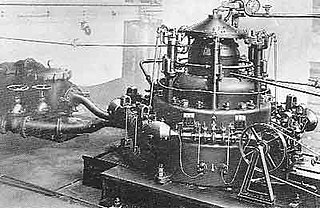

The Neuchâtel gas turbine is the world's first electric power-generating gas turbine to go into commercial operation. It was designed and constructed by Brown, Boveri & Cie and installed in 1939 at the municipal power station in Neuchâtel, Switzerland. The gas turbine was in service as a standby unit from 1940 until its retirement in 2002.

The Holzwarth gas turbine is a form of explosion, or constant volume, gas turbine in which combustion takes place cyclically in a combustion chamber closed off by valves. The Holzwarth gas turbine is named after its developer Dr Hans Holzwarth (1877-1953) who designed several prototype engines used for testing and experimental service in Germany and Switzerland between 1908 and 1943.