Related Research Articles

The Tellermine 35 (T.Mi.35) was a German metal-cased anti-tank mine used extensively during the Second World War. The mine's case is made of sheet steel, and has a slightly convex pressure plate on the top surface with a central fuze well. Two secondary fuze wells are located on the side and bottom of the mine for anti-handling devices.

The Tellermine 43 was a German circular steel cased anti-tank blast mine used during the Second World War. It was a simplified version of the Tellermine 42, which enabled simpler production techniques. Between March 1943 and the end of World War II, over 3.6 million Tellermine 43s were produced by Germany. Copies of the mine were produced by several countries including Denmark (M/47), France and Yugoslavia (TMM-1).

The PMN series of blast anti-personnel mines were designed and manufactured in the Soviet Union. They are one of the most widely used and commonly found devices during demining operations. They are sometimes nicknamed "black widow" because of their dark casings.

The PRB M3 and PRB M3A1 are plastic cased minimum metal anti-tank blast mine produced by the Belgian company Poudreries Réunies de Belgique in the 1970s and 1980s. The mine is square with an olive drab body constructed from polythene with a webbing carrying handle on the side and an ammonia-free bakelite seating for the pressure plate to be screwed into. The fuze well is in the centre of the seating, with the pressure plate screwed into it after the fuze has been inserted. The cylindrical pressure plate consists of two plastic plates, one of which moves under the weight of a vehicle driving over the mine to transmit the force to the fuze, shearing pins which hold it in place.

The M1, M1A1 and M4 are circular steel cased United States anti-tank blast mines with a distinctive cross shaped pressure spider. The mine was used during the Second World War and a copy produced in Argentina was used during the Falklands War. Another copy is produced in China, there designated as the No. 4 mine. Variants of the mine have also been deployed in Chad and Tunisia.

The M6, M6A1 and M6A2 are a series of metal-cased, circular, heavy anti-tank landmines produced by the United States from May 1944 to May 1945.

The Anti-Tank Mine, General Service, Mk V was a cylindrical, metal-cased United Kingdom anti-tank blast mine that entered service in 1943, during the Second World War. It was replaced in British service with the Mk 7 mine. Two versions of the mine were produced, the Mk. V and the Mk. VC with the same external dimensions. The only difference was that the Mk. VC had a half-sized explosive charge.

The TMA-1 and TMA-1A are circular, plastic cased Yugoslavian minimum metal anti-tank blast mine. The mine consists of an upper plastic pressure plate, and the lower body containing the main charge. The pressure plate has eight triangular raised sectors, and a central fuze cap. The pressure plate is held in place by four plastic pins, which when sufficient pressure is applied, shear allowing the pressure plate to collapse onto the mine body, triggering the UANU-1 fuze. A secondary fuze well is provided in the base of the mine, allowing the use of anti-handling devices. The mine is found in Bosnia, Croatia and Kosovo.

A minimum metal mine is a land mine that is designed to use the smallest amount of metal possible in its construction. Typically, the only metal components are located inside the fuze mechanism which triggers detonation. Both minimum metal anti-tank and anti-personnel mines exist. Some designs contain virtually no metal at all, e.g., less than a gram. This is achieved by encasing the explosive charge in a plastic, wooden, or glass body, with metallic components limited to the few small parts in the fuze which can not easily be made from other materials, such as the spring, striker tip, and shear pin. Minimum metal mines are extremely difficult to detect using conventional metal mine detectors and usually require modern techniques, such as robotic Multi Period Sensing (MPS) equipment, to identify, but it is still extremely difficult to find non-metallic mines. These techniques are usually restricted to well-funded international mine clearing organizations and major militaries, making minimum metal mines especially pernicious where they are encountered.

The TM-38 was a rectangular, metal-cased Soviet anti-tank mine used during the Second World War. The mine had a large raised rectangular central pressure plate with four reinforcing creases. When enough pressure was applied to the plate it collapses pressing down on a bolt connected to an internal lever. The lever pulls a retaining pin from the MUV fuze, which releases the striker, which impacts the MD-2 detonator.

The T-IV was a Soviet anti-tank mine developed before and used during the Second World War. The mine has a metal case with a wooden pressure plate attached to the top of the mine. It is similar in configuration to the later TM-38.

The Anti-Tank Mine General Service Mark II was a British anti-tank blast mine used during the Second World War. It consisted of a body about 7.5 in (190 mm) in diameter and 3.25 in (83 mm). The mine has a central fuze well accessed from the bottom, with a main charge in a cavity around the well consisting of about 4 lb (1.8 kg) of TNT. The mine is fitted with a thin brass cover, which acts as a pressure plate. The cover is suspended over the main body of the main by four leaf springs. A Sorbo ring can be fitted between the cover and the mine body, which absorbs shock and blast and allows the mines to be planted as close as two feet (0.61 m) without causing sympathetic detonation.

The Pignone mod.43 were bakelite cased Italian anti-tank blast mines used during the Second World War in North Africa and Italy.

The Anti-Tank Mine, General Service, Mark III was a British anti-tank mine used during World War II. The mine had a cylindrical tin lower body with a steel pressure plate which sits on top of a shear-wire restrained spring-loaded striker. Sufficient pressure on the cover shears the restraining wire, allowing the striker spring to push the striker into a 0.11 grams (1.7 gr) percussion cap. The flash from the percussion cap is transferred to the No.27 detonator which sits in the centre of the mine, detonating the device.

In military munitions, a fuze is the part of the device that initiates function. In some applications, such as torpedoes, a fuze may be identified by function as the exploder. The relative complexity of even the earliest fuze designs can be seen in cutaway diagrams.

The Shitotsubakurai lunge mine was a suicidal anti-tank weapon developed and used by the Empire of Japan during the Second World War. It used a HEAT type charge. This weapon was used by the CQC units of the Imperial Japanese Army. The weapon itself was a conical hollow charge anti-tank mine, placed inside a metallic container and attached to the end of a wooden stick. The weapon was officially adopted by the Japanese Army in 1945; in that year it caused its first victims in the Pacific Theater, where it commonly saw action against American armour. Later that year, some Japanese Imperial Army manuals of the weapon were discovered by US troops.

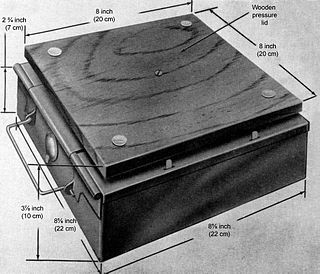

The Holzmine 42 was an anti-tank mine that was developed by Germany and used by the Wehrmacht during World War II.

The Anti-Tank Mine Egyptian Pattern Mark II was a British anti-tank mine used in World War II, produced near Cairo for use in extensive minefields in the North African campaign.

The A.T. Mine E.P. Mark V is a World War II British anti-tank mine, an improved version of previous A.T. Mine E.P.-type mines such as the A.T. Mine E.P. Mark II.

The A.T. Mine E.P.(Egyptian pattern) Mark VI was a World War II anti-tank mine.

References

- ↑ "USNBD, British Landmines, Fuzes and firing Devices; Section I - A/Tk Mines & Fuzes: A/Tk Mine G.S. Mk IV". michaelhiske.de. Retrieved 2021-01-31.

- ↑ "British Mines of the Second World War". www.wwiiequipment.com. Retrieved 2021-01-31.

- NAVORD OP 1665, British Explosive Ordnance, Naval Ordnance Systems Command (Updated 1970)