Smoke is a collection of airborne particulates and gases emitted when a material undergoes combustion or pyrolysis, together with the quantity of air that is entrained or otherwise mixed into the mass. It is commonly an unwanted by-product of fires, but may also be used for pest control (fumigation), communication, defensive and offensive capabilities in the military, cooking, or smoking. It is used in rituals where incense, sage, or resin is burned to produce a smell for spiritual or magical purposes. It can also be a flavoring agent and preservative.

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers.. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves sealing of piston rings, and cools the engine by carrying heat away from moving parts.

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

A nephelometer or aerosol photometer is an instrument for measuring the concentration of suspended particulates in a liquid or gas colloid. A nephelometer measures suspended particulates by employing a light beam and a light detector set to one side of the source beam. Particle density is then a function of the light reflected into the detector from the particles. To some extent, how much light reflects for a given density of particles is dependent upon properties of the particles such as their shape, color, and reflectivity. Nephelometers are calibrated to a known particulate, then use environmental factors (k-factors) to compensate lighter or darker colored dusts accordingly. K-factor is determined by the user by running the nephelometer next to an air sampling pump and comparing results. There are a wide variety of research-grade nephelometers on the market as well as open source varieties.

Aquatic toxicology is the study of the effects of manufactured chemicals and other anthropogenic and natural materials and activities on aquatic organisms at various levels of organization, from subcellular through individual organisms to communities and ecosystems. Aquatic toxicology is a multidisciplinary field which integrates toxicology, aquatic ecology and aquatic chemistry.

An electrostatic precipitator (ESP) is a filterless device that removes fine particles, like dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

A refractometer is a laboratory or field device for the measurement of an index of refraction (refractometry). The index of refraction is calculated from the observed refraction angle using Snell's law. For mixtures, the index of refraction then allows to determine the concentration using mixing rules such as the Gladstone–Dale relation and Lorentz–Lorenz equation.

Geotechnical investigations are performed by geotechnical engineers or engineering geologists to obtain information on the physical properties of soil earthworks and foundations for proposed structures and for repair of distress to earthworks and structures caused by subsurface conditions; this type of investigation is called a site investigation. Geotechnical investigations are also used to measure the thermal resistance of soils or backfill materials required for underground transmission lines, oil and gas pipelines, radioactive waste disposal, and solar thermal storage facilities. A geotechnical investigation will include surface exploration and subsurface exploration of a site. Sometimes, geophysical methods are used to obtain data about sites. Subsurface exploration usually involves soil sampling and laboratory tests of the soil samples retrieved.

A sieve analysis is a practice or procedure used in civil engineering and chemical engineering to assess the particle size distribution of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

The Proctor compaction test is a laboratory method of experimentally determining the optimal moisture content at which a given soil type will become most dense and achieve its maximum dry density. The test is named in honor of Ralph Roscoe Proctor, who in 1933 showed that the dry density of a soil for a given compactive effort depends on the amount of water the soil contains during soil compaction. His original test is most commonly referred to as the standard Proctor compaction test; his test was later updated to create the modified Proctor compaction test.

A landfill liner, or composite liner, is intended to be a low permeable barrier, which is laid down under engineered landfill sites. Until it deteriorates, the liner retards migration of leachate, and its toxic constituents, into underlying aquifers or nearby rivers, causing potentially irreversible contamination of the local waterway and its sediments.

A wood-burning stove is a heating or cooking appliance capable of burning wood fuel and wood-derived biomass fuel, such as sawdust bricks. Generally the appliance consists of a solid metal closed firebox, often lined by fire brick, and one or more air controls. The first wood-burning stove was patented in Strasbourg in 1557, two centuries before the Industrial Revolution, which would make iron an inexpensive and common material, so such stoves were high end consumer items and only gradually spread in use.

A gas pycnometer is a laboratory device used for measuring the density—or, more accurately, the volume—of solids, be they regularly shaped, porous or non-porous, monolithic, powdered, granular or in some way comminuted, employing some method of gas displacement and the volume:pressure relationship known as Boyle's Law. A gas pycnometer is also sometimes referred to as a helium pycnometer.

The Ringelmann scale is a scale for measuring the apparent density or opacity of smoke. It was developed by a French professor of agricultural engineering Maximilien Ringelmann of La Station d'Essais de Machines in Paris, who first specified the scale in 1888.

A Hegman gauge, sometimes referred to as a grind gauge, grind gage, or grindometer, is an instrument which indicates the fineness of grind or the presence of coarse particles and agglomeration in a dispersion. It is commonly used to determine how finely ground the particles of pigment dispersed in a sample of paint are. This is important because many types of solid materials must be ground into finer particles in order to be dispersed in liquids. The resulting properties of the dispersion vary based on the size of individual particles and the degree which they are dispersed.

Package testing or packaging testing involves the measurement of a characteristic or property involved with packaging. This includes packaging materials, packaging components, primary packages, shipping containers, and unit loads, as well as the associated processes.

Ultrapure water (UPW), high-purity water or highly purified water (HPW) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a term commonly used in manufacturing to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile; reactive, and inert; hydrophilic and hydrophobic; and dissolved gases.

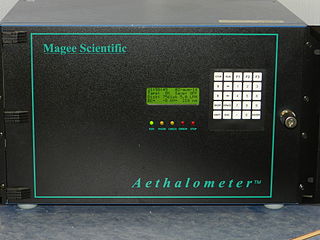

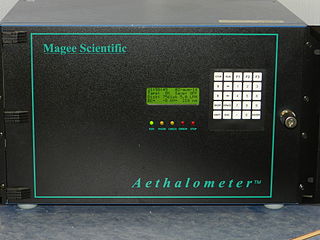

An aethalometer is an instrument for measuring the concentration of optically absorbing (‘black’) suspended particulates in a gas colloid stream; commonly visualized as smoke or haze, often seen in ambient air under polluted conditions. The word aethalometer is derived from the Classical Greek verb aethaloun, meaning "to blacken with soot".

Cyclic Corrosion Testing (CCT) has evolved in recent years, largely within the automotive industry, as a way of accelerating real-world corrosion failures, under laboratory controlled conditions. As the name implies, the test comprises different climates which are cycled automatically so the samples under test undergo the same sort of changing environment that would be encountered in the natural world. The intention being to bring about the type of failure that might occur naturally, but more quickly i.e. accelerated. By doing this manufacturers and suppliers can predict, more accurately, the service life expectancy of their products.

There are two different types of haze that can occur in materials: