Electronic data interchange (EDI) is the concept of businesses electronically communicating information that was traditionally communicated on paper, such as purchase orders, advance ship notices, and invoices. Technical standards for EDI exist to facilitate parties transacting such instruments without having to make special arrangements.

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels so that the raw materials can be converted into a finished product and delivered to the end customer. A more narrow definition of the supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally".This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

Logistics is a part of supply chain management that deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the point of consumption according to the needs of customers. Logistics management is a component that holds the supply chain together. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

Logistics automation is the application of computer software or automated machinery to improve the efficiency of logistics operations. Typically this refers to operations within a warehouse or distribution center, with broader tasks undertaken by supply chain engineering systems and enterprise resource planning systems.

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and personal use.

Cross-docking is a practice in logistics of unloading materials from a manufacturer or mode of transportation directly to the customer or another mode of transportation, with little or no storage in between. This may be done to change the type of conveyance, to sort material intended for different destinations, or to combine material from different origins into transport vehicles with the same or similar destinations.

A receipt is a document acknowledging that a person has received money or property in payment following a sale or other transfer of goods or provision of a service. All receipts must have the date of purchase on them. If the recipient of the payment is legally required to collect sales tax or VAT from the customer, the amount would be added to the receipt, and the collection would be deemed to have been on behalf of the relevant tax authority. In many countries, a retailer is required to include the sales tax or VAT in the displayed price of goods sold, from which the tax amount would be calculated at the point of sale and remitted to the tax authorities in due course. Similarly, amounts may be deducted from amounts payable, as in the case of taxes withheld from wages. On the other hand, tips or other gratuities that are given by a customer, for example in a restaurant, would not form part of the payment amount or appear on the receipt.

A distribution center for a set of products is a warehouse or other specialized building, often with refrigeration or air conditioning, which is stocked with products (goods) to be redistributed to retailers, to wholesalers, or directly to consumers. A distribution center is a principal part, the order processing element, of the entire order fulfillment process. Distribution centers are usually thought of as being demand driven. A distribution center can also be called a warehouse, a DC, a fulfillment center, a cross-dock facility, a bulk break center, and a package handling center. The name by which the distribution center is known is commonly based on the purpose of the operation. For example, a "retail distribution center" normally distributes goods to retail stores, an "order fulfillment center" commonly distributes goods directly to consumers, and a cross-dock facility stores little or no product but distributes goods to other destinations.

Supply chain security activities aim to enhance the security of the supply chain or value chain, the transport and logistics systems for the world's cargo and to "facilitate legitimate trade". Their objective is to combine traditional practices of supply-chain management with the security requirements driven by threats such as terrorism, piracy, and theft.

The Serial Shipping Container Code (SSCC) is an 18-digit number used to identify logistics units. In order to automate the reading process, the SSCC is often encoded in a barcode, generally GS1-128, and can also be encoded in an RFID tag. It is used in electronic commerce transactions.

MIL-STD-129 standard is used for maintaining uniformity while marking military equipment and supplies that are transported through ships. This standard has been approved to be used by the United States Department of Defense and all other government agencies. Items must be marked for easy identification before they are transported. The marking helps the military personnel to fill the necessary requisition, when a particular stock goes short of the balance level.

The Automotive Industry Action Group (AIAG) is a not-for-profit association founded in 1982 and based in Southfield, Michigan. It was originally created to develop recommendations and a framework for the improvement of quality in the North American automotive industry. The association's areas of interest have expanded to include product quality standards, bar code and RFID standards, materials management, EDI, returnable containers and packaging systems, and regulatory and customs issues.

Merge-in-transit (MIT) is a distribution method in which several shipments from suppliers originating at different locations are consolidated into one final customer delivery. This removes the need for distribution warehouses in the supply chain, allowing customers to receive complete deliveries for their orders. Under a merge-in-transit system, merge points replace distribution warehouse. In today's global market, merge-in-transit is progressively being used in telecommunications and electronic industries. These industries are usually dynamic and flexible, in which products have been developed and changed rapidly.

Corrugated box design is the process of matching design factors for corrugated fiberboard boxes with the functional physical, processing and end-use requirements. Packaging engineers work to meet the performance requirements of a box while controlling total costs throughout the system.

Package testing or packaging testing involves the measurement of a characteristic or property involved with packaging. This includes packaging materials, packaging components, primary packages, shipping containers, and unit loads, as well as the associated processes.

Third-party logistics is an organization's long term commitment of outsourcing its distribution services to third-party logistics businesses.

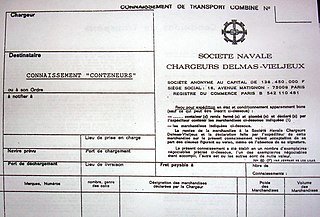

A bill of lading is a document issued by a carrier to acknowledge receipt of cargo for shipment. Although the term historically related only to carriage by sea, a bill of lading may today be used for any type of carriage of goods. Bills of lading are one of three crucial documents used in international trade to ensure that exporters receive payment and importers receive the merchandise. The other two documents are a policy of insurance and an invoice. Whereas a bill of lading is negotiable, both a policy and an invoice are assignable. In international trade outside the United States, bills of lading are distinct from waybills in that the latter are not transferable and do not confer title. Nevertheless, the UK Carriage of Goods by Sea Act 1992 grants "all rights of suit under the contract of carriage" to the lawful holder of a bill of lading, or to the consignee under a sea waybill or a ship's delivery order.

A freight claim or cargo claim is a legal demand by a shipper or consignee against a carrier in respect of damage to a shipment, or loss thereof.

GS1 EDI is a set of global electronic messaging standards for business documents used in Electronic Data Interchange (EDI). The standards are developed and maintained by GS1. GS1 EDI is part of the overall GS1 system, fully integrated with other GS1 standards, increasing the speed and accuracy of the supply chain. Examples of GS1 EDI standards include messages such as: Order, Despatch Advice, Invoice, Transport Instruction, etc. The development and maintenance of all GS1 standards is based on a rigorous process called the Global Standard Management Process (GSMP). GS1 develops its global supply chain standards in partnership with the industries using them. Any organization can submit a request to modify the standard. Maintenance releases of GS1 EDI standards are typically published every two years, while code lists can be updated up to 4 times a year.

A transportation and warehouse management system (TWMS) is a software application that supports eCommerce, distribution, and third-party logistics (3PL) companies within supply chain management.