Related Research Articles

A photograph is an image created by light falling on a photosensitive surface, usually photographic film or an electronic image sensor, such as a CCD or a CMOS chip. Most photographs are now created using a smartphone/camera, which uses a lens to focus the scene's visible wavelengths of light into a reproduction of what the human eye would see. The process and practice of creating such images is called photography.

A blueprint is a reproduction of a technical drawing or engineering drawing using a contact print process on light-sensitive sheets. Introduced by Sir John Herschel in 1842, the process allowed rapid and accurate production of an unlimited number of copies. It was widely used for over a century for the reproduction of specification drawings used in construction and industry. The blueprint process was characterized by white lines on a blue background, a negative of the original. The process was not able to reproduce color or shades of grey.

BoPET is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties, and electrical insulation. A variety of companies manufacture boPET and other polyester films under different brand names. In the UK and US, the best-known trade names are Mylar, Melinex, and Hostaphan.

Photographic paper is a paper coated with a light-sensitive chemical formula, like photographic film, used for making photographic prints. When photographic paper is exposed to light, it captures a latent image that is then developed to form a visible image; with most papers the image density from exposure can be sufficient to not require further development, aside from fixing and clearing, though latent exposure is also usually present. The light-sensitive layer of the paper is called the emulsion. The most common chemistry was based on silver halide but other alternatives have also been used.

Shrink wrap, also shrink film, is a material made up of polymer plastic film. When heat is applied, it shrinks tightly over whatever it is covering. Heat can be applied with a handheld heat gun, or the product and film can pass through a heat tunnel on a conveyor.

Whiteprint describes a document reproduction produced by using the diazo chemical process. It is also known as the blue-line process since the result is blue lines on a white background. It is a contact printing process which accurately reproduces the original in size, but cannot reproduce continuous tones or colors. The light-sensitivity of the chemicals used was known in the 1890s and several related printing processes were patented at that time. Whiteprinting replaced the blueprint process for reproducing architectural and engineering drawings because the process was simpler and involved fewer toxic chemicals. A blue-line print is not permanent and will fade if exposed to light for weeks or months, but a drawing print that lasts only a few months is sufficient for many purposes.

Drawing is a metalworking process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing. Sheet metal drawing is defined as a plastic deformation over a curved axis. For wire, bar, and tube drawing, the starting stock is drawn through a die to reduce its diameter and increase its length. Drawing is usually performed at room temperature, thus classified as a cold working process; however, drawing may also be performed at higher temperatures to hot work large wires, rods, or hollow tubes in order to reduce forces.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobiles, and bicycle frames. Advancements in powder coating technology like UV curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF to be powder coated due to the minimum heat and oven dwell time required to process these components.

Sailcloth encompasses a wide variety of materials that span those from natural fibers, such as flax, hemp or cotton in various forms of sail canvas, to synthetic fibers, including nylon, polyester, aramids, and carbon fibers in a variety of woven, spun and molded textiles.

Vinyl coated polyester is a material frequently used for flexible fabric structures. It is made up of a polyester scrim, a bonding or adhesive agent, and an exterior PVC coating. The scrim supports the coating and provides the tensile strength, elongation, tear strength, and dimensional stability of the resulting fabric. Depending on its formula, the PVC coating makes the material waterproof and resistant to dirt, mildew, oil, salt, chemicals and UV rays and gives the material added strength and durability. It can be sewn or heat sealed by way of RF(Radio Frequency) welding or hot-air welding.

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls the material.

A canvas print is the result of an image printed onto canvas which is often stretched, or gallery-wrapped, onto a frame and displayed. Canvas prints are used as the final output in an art piece, or as a way to reproduce other forms of art.

From the late 19th century until the middle of the 20th century, drafting linen, also known as drafting cloth, was commonly used as an alternative to wood-pulp and rag papers in creating technical drawings. Its major benefits were considerable strength, especially in erasing and redrawing, durability in handling, and translucency for making multiple reprographic prints. Manufactured as an undyed muslin woven fabric, typically using cotton or linen fiber, the textile was highly starched and then calendered to create a smooth surface for precise ink and graphite lines. Although drafting linen was most typically used in creating original drawings, it was occasionally used as the underlying support for blueprints and other similar reprographic processes. Drafting linen largely fell out of favor after the development of drafting film — varying in chemical composition from cellulose acetate to polyester—in the 1950s.

A fabric structure is a structure made of fabric, with or without a structural frame. The technology provides end users a variety of aesthetic free-form building designs. Custom-made structures are engineered and fabricated to meet worldwide structural, flame retardant, weather-resistant, and natural force requirements. Fabric structures are considered a sub-category of tensile structure.

Drafting tools may be used for measurement and layout of drawings, or to improve the consistency and speed of creation of standard drawing elements. Tools such as pens and pencils mark the drawing medium. Other tools such as straight edges, assist the operator in drawing straight lines, or assist the operator in drawing complicated shapes repeatedly. Various scales and the protractor are used to measure the lengths of lines and angles, allowing accurate scale drawing to be carried out. The compass is used to draw arcs and circles. A drawing board was used to hold the drawing media in place; later boards included drafting machines that sped the layout of straight lines and angles. Tools such as templates and lettering guides assisted in the drawing of repetitive elements such as circles, ellipses, schematic symbols and text. Other auxiliary tools were used for special drawing purposes or for functions related to the preparation and revision of drawings. The tools used for manual technical drawing have been displaced by the advent of computer-aided drawing, drafting and design (CADD).

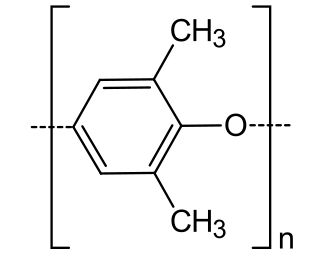

Poly(p-phenylene oxide) (PPO), poly(p-phenylene ether) (PPE), often referred to simply as polyphenylene oxide, is a high-temperature thermoplastic. It is rarely used in its pure form due to difficulties in processing. It is mainly used as blend with polystyrene, high impact styrene-butadiene copolymer or polyamide. PPO is a registered trademark of SABIC Innovative Plastics B.V. under which various polyphenylene ether resins are sold.

Dimensional stability is the change of dimensions in textile products when they are washed or relaxed. The change is always expressed relative to the dimensions before the exposure of washing or relaxing. Shrinkage is also called residual shrinkage and measured in percentage. The major cause of shrinkages is the release of stresses and strains introduced in manufacturing processes. Textile manufacturing is based on the conversion of fiber into yarn, yarn into fabric, includes spinning, weaving, or knitting, etc. The fabric passes through many inevitable changes and mechanical forces during this journey. When the products are immersed in water, the water acts as a relaxing medium, and all stresses and strains are relaxed and the fabric tries to come back to its original state. The dimensional stability of textile materials is an important quality parameter. Failing and unstable materials can cause deforming of the garments or products. Shrinkage is tested at various stages, but most importantly before cutting the fabric into further sewn products and after cutting and sewing prior to supplying the products to buyers and consumers. It is a required parameter of quality control to ensure the sizes of the products to avoid any complaints regarding deformation or change in dimensions after domestic laundry. The tests are conducted with provided specifications of buyers imitating the same conditions like washing cycle time, temperature and water ratio and fabric load and sometimes top loading and front loading washing machines are chosen to authenticate the test and assurance of the results. This procedure provides standard and alternate home laundering conditions using an automatic washing machine. While the procedure includes several options, it is not possible to include every existing combination of laundering parameters. The test is applicable to all fabrics and end products suitable for home laundering.

Drafting film is a sturdier and more dimensionally stable substitute for drafting paper sometimes used for technical drawings, especially architectural drawings, and for art layout drawings, replacing drafting linen for these purposes. Nowadays it is almost invariably made of transparent biaxially oriented polyethylene terephthalate, which should last several centuries under normal storage conditions, with one or two translucent matte surfaces provided by a coating. However, some older drafting films are cellulose acetate, which degrades in only a few decades due to the vinegar syndrome. Uncoated films are preferred for archival, because there is then no possibility that the coating material could deteriorate over time or react with other materials.

The lining of paintings is a process of conservation science and art restoration used to strengthen, flatten or consolidate oil or tempera paintings on canvas by attaching a new support to the back of the existing one. The process is sometimes referred to as relining. Most often a new support will be added directly to the back of an existing canvas. In cases of extreme decay, however, the original canvas may be completely removed and replaced. The height of the practice's use peaked in the late 19th century and in the following years its usefulness has been debated. There are many different factors that influence whether lining a painting will be successful. By paying close attention to an artwork's condition and response to treatment, conservation professionals better understand the lining process and when to apply it.

The conservation and restoration of film is the physical care and treatment of film-based materials. These include photographic film and motion picture film stock.

References

- ↑ American Society of Mechanical Engineers, 2008, "Undimensioned Drawings", ASME Y14.31-2008, ¶4, "Drawings that require strength, durability, and dimensional stability shall be prepared on Class 1 polyester film..."