Related Research Articles

A gas mask is a mask used to protect the wearer from inhaling airborne pollutants and toxic gases. The mask forms a sealed cover over the nose and mouth, but may also cover the eyes and other vulnerable soft tissues of the face. Most gas masks are also respirators, though the word gas mask is often used to refer to military equipment, the scope used in this article. The gas mask only protects the user from digesting, inhaling and contact through the eyes. Most combined gas mask filters will last around 8 hours in a nuclear biological chemical (NBC) situation. Chemical specific filters can last up to 20 hours in an NBC situation.

Bacteriological water analysis is a method of analysing water to estimate the numbers of bacteria present and, if needed, to find out what sort of bacteria they are. It represents one aspect of water quality. It is a microbiological analytical procedure which uses samples of water and from these samples determines the concentration of bacteria. It is then possible to draw inferences about the suitability of the water for use from these concentrations. This process is used, for example, to routinely confirm that water is safe for human consumption or that bathing and recreational waters are safe to use.

High-efficiency particulate air (HEPA), also known as high-efficiency particulate absorbing and high-efficiency particulate arrestance, is an efficiency standard of air filter.

A surgical mask, also known as a face mask, is intended to be worn by health professionals during healthcare procedures. It is designed to prevent infections in patients and treating personnel by catching bacteria shed in liquid droplets and aerosols from the wearer's mouth and nose. They are not designed to protect the wearer from breathing in airborne bacteria or viruses whose particles are smaller. With respect to some infections like influenza they appear as effective as respirators, such as N95 or FFP masks; though the latter provide better protection in laboratory experiments due to their material, shape and tight seal.

Nomex is a flame-resistant meta-aramid material developed in the early 1960s by DuPont and first marketed in 1967.

A respirator is a device designed to protect the wearer from inhaling hazardous atmospheres, including fumes, vapours, gases and particulate matter such as dusts and airborne microorganisms. There are two main categories: the air-purifying respirator, in which respirable air is obtained by filtering a contaminated atmosphere, and the air-supplied respirator, in which an alternate supply of breathable air is delivered. Within each category, different techniques are employed to reduce or eliminate noxious airborne contaminants.

ULPA is an acronym for "Ultra Low Particulate Air (filter)" An ULPA filter can remove from the air at least 99.999% of dust, pollen, mold, bacteria and any airborne particles with a minimum particle penetration size of 100 nanometres (0.1 µm). A ULPA filter can remove – oil smoke, tobacco smoke, rosin smoke, smog, insecticide dust.

The standard penetration test (SPT) is an in-situ dynamic penetration test designed to provide information on the geotechnical engineering properties of soil. This test is the most frequently used subsurface exploration drilling test performed worldwide. The test procedure is described in ISO 22476-3, ASTM D1586 and Australian Standards AS 1289.6.3.1. The test provides samples for identification purposes and provides a measure of penetration resistance which can be used for geotechnical design purposes. Many local and widely published international correlations which relate blow count, or N-value, to the engineering properties of soils are available for geotechnical engineering purposes.

Nonwoven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

Geotechnical investigations are performed by geotechnical engineers or engineering geologists to obtain information on the physical properties of soil earthworks and foundations for proposed structures and for repair of distress to earthworks and structures caused by subsurface conditions. This type of investigation is called a site investigation. Additionally, geotechnical investigations are also used to measure the thermal resistivity of soils or backfill materials required for underground transmission lines, oil and gas pipelines, radioactive waste disposal, and solar thermal storage facilities. A geotechnical investigation will include surface exploration and subsurface exploration of a site. Sometimes, geophysical methods are used to obtain data about sites. Subsurface exploration usually involves soil sampling and laboratory tests of the soil samples retrieved.

Ultrapure water (UPW), high-purity water or highly purified water (HPW) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a commonly used term in the semiconductor industry to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile, reactive and inert; hydrophilic and hydrophobic; and dissolved gases.

A respirator fit test checks whether a respirator properly fits the face of someone who wears it. The fitting characteristic of a respirator is the ability of the mask to separate a worker's respiratory system from ambient air.

The NIOSH air filtration rating is the U.S. National Institute for Occupational Safety and Health (NIOSH)'s classification of filtering respirators. The ratings describe the ability of the device to protect the wearer from dust and liquid droplets in the air. The certification and approval process for respiratory protective devices is governed by Part 84 of Title 42 of the Code of Federal Regulations. Respiratory protective devices so classified include air-purifying respirators (APR) such as filtering facepiece respirators and chemical protective cartridges that have incorporated particulate filter elements.

The respiratory protective devices (RPD) can protect workers only if their protective properties are adequate to the conditions in the workplace. Therefore, specialists have developed criteria for the selection of proper, adequate respirators, including the Assigned Protection Factors (APF) - the decrease of the concentration of harmful substances in the inhaled air, which to be provided with timely and proper use of a certified respirator of certain types (design) by taught and trained workers, when the employer performs an effective respiratory protective device programme.

An N95 mask or N95 respirator is a particulate-filtering facepiece respirator that meets the U.S. National Institute for Occupational Safety and Health (NIOSH) N95 classification of air filtration, meaning that it filters at least 95% of airborne particles. This standard does not require that the respirator be resistant to oil; another standard, P95, adds that requirement. The N95 type is the most common particulate-filtering facepiece respirator. It is an example of a mechanical filter respirator, which provides protection against particulates but not against gases or vapors.

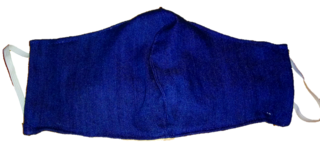

A cloth face mask is a mask made of common textiles, usually cotton, worn over the mouth and nose. When more effective masks are not available, and when physical distancing is impossible, cloth face masks are recommended by public health agencies for disease "source control" in epidemic situations to protect others from virus laden droplets in infected mask wearers' breath, coughs, and sneezes. Because they are less effective than N95 masks, surgical masks, or physical distancing in protecting the wearer against viruses, they are not considered to be personal protective equipment by public health agencies. They are used by the general public in household and community settings as perceived protection against both infectious diseases and particulate air pollution.

An FFP mask is a type of protective mask certified by the European Union that serves to protect against particulates such as dust particles. The EN 149 standard defines three classes of filter efficiency for these masks, namely FFP1, FFP2 and FFP3. It is an example of a mechanical filter respirator.

Mechanical filter respirators are a class of respirator that removes particulates from the air using a filter that mechanically stops them from reaching the wearer's nose and mouth.

Source control is a strategy for reducing disease transmission by blocking respiratory secretions produced through speaking, coughing, or sneezing. Surgical masks are commonly used for this purpose, with cloth face masks recommended for use by the public only in epidemic situations when there are shortages of surgical masks. In addition, respiratory etiquette such as covering the mouth and nose with a tissue when coughing can be considered source control.

References

- ↑ http://www.kchealthcare.com/media/287706/h0486_0701_medlinevskc.pdf%5B%5D

- ↑ Robertson, Paddy (15 March 2020). "Comparison of Mask Standards, Ratings, and Filtration Effectiveness". Smart Air Filters.