Blackplate is hot rolled or cold rolled, [1] non-descaled sheet steel or sheet iron. [2]

Blackplate is hot rolled or cold rolled, [1] non-descaled sheet steel or sheet iron. [2]

Blackplate is made of non-tinned [2] iron or steel and is annealed on open flames or in an annealing box. [3] Its dark appearance is caused by its reaction with the surrounding air. [3] During warm rolling, blackplate can be manufactured to thicknesses of 1.5 mm or more. [4] Cold rolled blackplate, by contrast, can be made thinner – thicknesses of 0.4 to 1.5 mm being attainable – and produces better surface qualities. [4]

Stainless steel, also known as inox, corrosion-resistant steel (CRES), and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains iron with chromium and other elements such as molybdenum, carbon, nickel and nitrogen depending on its specific use and cost. Stainless steel's resistance to corrosion results from the 10.5%, or more, chromium content which forms a passive film that can protect the material and self-heal in the presence of oxygen.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °C (842 °F). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that protects the steel underneath from further corrosion in many circumstances. Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel, and is considered superior in terms of cost and life-cycle. It can be identified by the crystallization patterning on the surface (often called a "spangle").

Cookware and bakeware is food preparation equipment, such as cooking pots, pans, baking sheets etc. used in kitchens. Cookware is used on a stove or range cooktop, while bakeware is used in an oven. Some utensils are considered both cookware and bakeware.

Corrugated galvanised iron (CGI) or steel, colloquially corrugated iron, wriggly tin, pailing, corrugated sheet metal, zinc or custom orb / corro sheet (Australia), is a building material composed of sheets of hot-dip galvanised mild steel, cold-rolled to produce a linear ridged pattern in them. Although it is still popularly called "iron" in the UK, the material used is actually steel, and only the surviving vintage sheets may actually be made up of 100% iron. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them, because the steel must be stretched to bend perpendicular to the corrugations. Normally each sheet is manufactured longer in its strong direction.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing. Sheet metal drawing is defined as a plastic deformation over a curved axis. For wire, bar, and tube drawing, the starting stock is drawn through a die to reduce its diameter and increase its length. Drawing is usually performed at room temperature, thus classified as a cold working process; however, drawing may also be performed at higher temperatures to hot work large wires, rods, or hollow tubes in order to reduce forces.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Before the advent of cheap mild steel, the backing metal was wrought iron. While once more widely used, the primary use of tinplate now is the manufacture of tin cans.

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. The term is also widely used for the different process of coating a metal with solder before soldering.

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel, bar stock, and rails. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.

Electrical steel is speciality steel used in the cores of electromagnetic devices such as motors, generators, and transformers because it reduces power loss. It is an iron alloy with silicon as the main additive element. The exact formulation is tailored to produce specific magnetic properties: small hysteresis area resulting in low power loss per cycle, low core loss, and high permeability.

Architectural glass is glass that is used as a building material. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type, which include reinforced, toughened and laminated glasses.

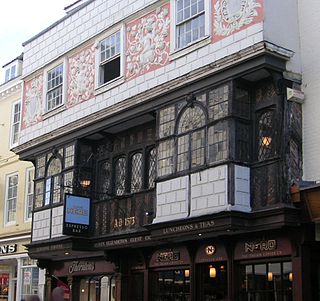

A tin ceiling is an architectural element, consisting of a ceiling finished with tinplate with designs pressed into them, that was very popular in Victorian buildings in North America in the late 19th and early 20th century. They were also popular in Australia where they were commonly known as pressed metal ceilings or Wunderlich ceilings. They were also used in South Africa.

Mobarakeh Steel Company is a private Iranian steel company, located 65 km south west of Esfahan, near the city of Mobarakeh, Esfahan Province, Iran. It is the largest steel maker of MENA region, and one of the largest industrial complexes operating in Iran. It was commissioned after the Iranian Revolution in 1979 and initiated operations during 1993. It underwent major revamping during year 2000, and is scheduled for a second and third revamping in 2009–2010, bringing the total steel output to 7,200,000 metric tons per year. The company owns the successful football club, Sepahan. In, 2022, this company employs over 14,000 people and generates more than 5.5 billion dollars per year. The company is not only a steel producer but also owns a number of other small steel producer, power plants, substations, mines, and a gas field.

A glass cutter is a tool used to make a shallow score in one surface of a piece of glass that is to be broken in two pieces, for example to fit a window. The scoring makes a split in the surface of the glass which encourages the glass to break along the score. This is not to be confused with the tools used to make cut glass objects.

Soken tester - is a portable single yoke instrument for assessing the power loss in electrical steel laminations.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

This steelmaking plant was originally part of the Ford Motor Company, which created an integrated manufacturing complex to produce all major vehicle components at one large facility called The Rouge. In 1989, Ford's steel mill assets were divested and became known as Rouge Industries with the steel operations trading as Rouge Steel Company in Dearborn, Michigan, outside of Detroit.

A tandem rolling mill is a rolling mill used to produce wire and sheet metal. It is composed of two or more close-coupled stands, and uses tension between the stands as well as compressive force from work rolls to reduce the thickness of steel. It was first patented by Richard Ford in 1766 in England.