The Federal Aviation Regulations (FARs) are rules prescribed by the Federal Aviation Administration (FAA) governing all aviation activities in the United States. The FARs comprise Title 14 of the Code of Federal Regulations (CFR). A wide variety of activities are regulated, such as aircraft design and maintenance, typical airline flights, pilot training activities, hot-air ballooning, lighter-than-air aircraft, man-made structure heights, obstruction lighting and marking, model rocket launches, commercial space operations, model aircraft operations, Unmanned Aircraft Systems (UAS) and kite flying. The rules are designed to promote safe aviation, protecting pilots, flight attendants, passengers and the general public from unnecessary risk.

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a portmanteau of "turbine" and "fan": the turbo portion refers to a gas turbine engine which achieves mechanical energy from combustion, and the fan, a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

Kaman Corporation is an American aerospace company, with headquarters in Bloomfield, Connecticut. It was founded in 1945 by Charles Kaman. During the first ten years the company operated exclusively as a designer and manufacturer of several helicopters that set world records and achieved many aviation firsts.

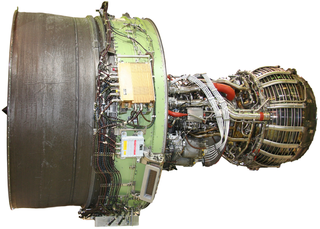

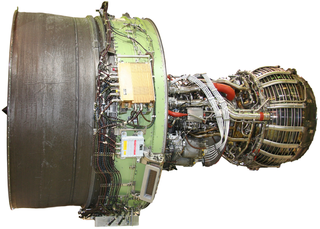

The Pratt & Whitney PW4000 is a family of dual-spool, axial-flow, high-bypass turbofan aircraft engines produced by Pratt & Whitney as the successor to the JT9D. It was first run in April 1984, was FAA certified in July 1986, and was introduced in June 1987. With thrust ranging from 50,000 to 99,040 lbf, it is used on many wide-body aircraft.

The General Electric GE90 is a family of high-bypass turbofan aircraft engines built by GE Aviation for the Boeing 777, with thrust ratings from 81,000 to 115,000 lbf. It entered service with British Airways in November 1995. It is one of three options for the 777-200, -200ER, and -300 versions, and the exclusive engine of the -200LR, -300ER, and 777F. It was the largest jet engine, until being surpassed in January 2020 by its successor, the 110,000 lbf (490 kN) GE9X, which has a 6 in (15 cm) larger diameter fan. The GE90, however, is still more powerful than its successor, the GE9X.

A propfan, also called an open rotor engine, or unducted fan, is a type of aircraft engine related in concept to both the turboprop and turbofan, but distinct from both. The design is intended to offer the speed and performance of a turbofan, with the fuel economy of a turboprop. A propfan is typically designed with a large number of short, highly twisted blades, similar to the (ducted) fan in a turbofan engine. For this reason, the propfan has been variously described as an "unducted fan" (UDF) or an "ultra-high-bypass (UHB) turbofan."

The General Electric GEnx is an advanced dual rotor, axial flow, high-bypass turbofan jet engine in production by GE Aviation for the Boeing 787 and 747-8. The GEnx is intended to succeed the CF6 in GE's product line.

The General Electric CF6, US military designations F103 and F138, is a family of high-bypass turbofan engines produced by GE Aviation. Based on the TF39, the first high-power high-bypass jet engine, the CF6 powers a wide variety of civilian airliners. The basic engine core also powers the LM2500 and LM6000 marine and power generation turboshafts. It is gradually being replaced by the newer GEnx family.

A light-sport aircraft (LSA), or light sport aircraft, is a fairly new category of small, lightweight aircraft that are simple to fly. LSAs tend to be heavier and more sophisticated than ultralight aircraft, but LSA restrictions on weight and performance separates the category from established GA aircraft. There is no standard worldwide description of an LSA.

The Rolls-Royce Trent 1000 is a high-bypass turbofan engine produced by Rolls-Royce plc, one of the two engine options for the Boeing 787 Dreamliner, competing with the General Electric GEnx. It first ran on 14 February 2006 and first flew on 18 June 2007 before a joint EASA/FAA certification on 7 August 2007 and entered service on 26 October 2011. Corrosion-related fatigue cracking of intermediate pressure (IP) turbine blades was discovered in early 2016, grounding up to 44 aircraft and costing Rolls-Royce at least £1.354 billion.

A blade inspection method is the practice of monitoring the condition of a blade, such as a helicopter's rotor blade, for deterioration or damage. A common area of focus in the aviation industry has been the detection of cracking, which is commonly associated with fatigue. Automated blade condition monitoring technology has been developed for helicopters and has seen widespread adoption. The technique is routinely mandated by airworthiness authorities for engine inspections. Another commercial sector where such monitoring has become important is electricity generation, particularly on wind farms.

A turbine engine failure occurs when a turbine engine unexpectedly stops producing power due to a malfunction other than fuel exhaustion. It often applies for aircraft, but other turbine engines can fail, like ground-based turbines used in power plants or combined diesel and gas vessels and vehicles.

The Pratt & Whitney PW1000G, also called the Geared Turbofan (GTF), is a high-bypass geared turbofan engine family produced by Pratt & Whitney. After many demonstrators, the program was launched with the Mitsubishi MRJ's PW1200G in March 2008, and it was first flight tested in July 2008. The first variant to be certified was the PW1500G for the Airbus A220 in February 2013. The program cost is estimated at $10 billion.

Los Angeles Airways Flight 417 was a Sikorsky S-61 helicopter that crashed on August 14, 1968 in the city of Compton, California. All eighteen passengers and three crew members were killed. The aircraft was destroyed by impact and fire. According to the National Transportation Safety Board the probable cause of the accident was fatigue failure. The accident happened when the yellow blade, one of five main rotor blades, separated at the spindle which attached the blade to the rotor head. Following failure, the helicopter was uncontrollable and it fell to the ground. The fatigue crack originated in an area of substandard hardness and inadequate shot peening.

The exoskeletal engine (ESE) is a concept in turbomachinery design. Current gas turbine engines have central rotating shafts and fan-discs and are constructed mostly from heavy metals. They require lubricated bearings and need extensive cooling for hot components. They are also subject to severe imbalance that could wipe out the whole rotor stage, are prone to high- and low-cycle fatigue, and subject to catastrophic failure due to disc bursts from high tensile loads, consequently requiring heavy containment devices. To address these limitations, the ESE concept turns the conventional configuration inside-out and utilizes a drum-type rotor design for the turbomachinery in which the rotor blades are attached to the inside of a rotating drum instead of radially outwards from a shaft and discs. Multiple drum rotors could be used in a multi-spool design.

An airbreathing jet engine is a jet engine that ejects a propelling (reaction) jet of hot exhaust gases after first taking in atmospheric air, followed by compression, heating and expansion back to atmospheric pressure through a nozzle. Alternatively the reaction jet may include a cold jet of ducted bypass air which has been compressed by a fan before returning to atmospheric pressure through an additional nozzle. These engines are gas turbine engines. Engines using only ram for the compression process, and no turbomachinery, are the ramjet and pulsejet.

The General Electric Passport is a turbofan developed by GE Aviation for large business jets. It was selected in 2010 to power the Bombardier Global 7500/8000, first run on June 24, 2013, and first flown in 2015. It was certified in April 2016 and powered the Global 7500 first flight on November 4, 2016, before its 2018 introduction. It produces 14,000 to 20,000 lbf of thrust, a range previously covered by the General Electric CF34. A smaller scaled CFM LEAP, it is a twin-spool axial engine with a 5.6:1 bypass ratio and a 45:1 overall pressure ratio and is noted for its large one-piece 52 in (130 cm) fan 18-blade titanium blisk.

The General Electric GE9X is a high-bypass turbofan developed by GE Aviation exclusively for the Boeing 777X. It first ran on the ground in April 2016 and first flew on March 13, 2018; it powered the 777-9's maiden flight in early 2020. It received its Federal Aviation Administration (FAA) type certificate on September 25, 2020. Derived from the General Electric GE90 with a larger fan, advanced materials like ceramic matrix composites (CMCs), and higher bypass and compression ratios, it was designed to improve fuel efficiency by 10% compared to the GE90. It is rated at 110,000 lbf (490 kN) of thrust, which is 5,000 lbf less than the GE90 highest thrust variant, the GE90-115 rated at 115,000 lbf (510 kN).

The General Electric Catalyst is a turboprop engine by GE Aviation. It was announced on 16 November 2015 and will power the Beechcraft Denali, it first ran on December 22, 2017, and should be certified in 2023. The 850 to 1,600 hp engine aims for 20% better efficiency than its competition thanks to a 16:1 overall pressure ratio, variable stator vanes, cooled turbine blades, 3D printed parts and FADEC.

Southwest Airlines Flight 1380 was a Boeing 737-7H4 that experienced a contained engine failure in the left CFM56-7B engine after departing from New York–LaGuardia Airport en route to Dallas Love Field on April 17, 2018. The engine cowl was broken in the failure and cowl fragments damaged the fuselage, causing explosive depressurization of the aircraft after damaging a cabin window. Other fragments caused damage to the wing. The crew carried out an emergency descent and diverted to Philadelphia International Airport. One passenger was partially ejected from the aircraft and later died. Eight other passengers received minor injuries. The aircraft was substantially damaged.