This article needs additional citations for verification .(April 2009) |

A bob is the mass on the end of a pendulum found most commonly, but not exclusively, in pendulum clocks.

This article needs additional citations for verification .(April 2009) |

A bob is the mass on the end of a pendulum found most commonly, but not exclusively, in pendulum clocks.

Although a pendulum can theoretically be any shape, any rigid object swinging on a pivot, clock pendulums are usually made of a weight or bob attached to the bottom end of a rod, with the top attached to a pivot so it can swing. The advantage of this construction is that it positions the centre of mass close to the physical end of the pendulum, farthest from the pivot. This maximizes the moment of inertia, and minimises the length of pendulum required for a given period. Shorter pendulums allow the clock case to be made smaller, and also minimize the pendulum's air resistance. Since most of the energy loss in clocks is due to air friction of the pendulum, this allows clocks to run longer on a given power source.

Traditionally, a clock pendulum bob is a round flat disk, lens-shaped in section, to reduce its aerodynamic drag, but bobs in older clocks often have decorative carving and shapes characteristic of the type of clock. They are usually made of a dense metal such as iron or brass. Lead is denser, but is usually avoided because of its softness, which would result in the bob being dented during its inevitable collisions with the inside of the clock case when the clock is moved.

In most pendulum clocks the rate is adjusted by moving the bob up or down on the pendulum rod. Moving it up shortens the pendulum, making it beat more quickly, and causing the clock to gain time. In the most common arrangement, the bob is attached to the pendulum with an adjustment nut at the bottom, on the threaded end of the pendulum rod. Turning the nut adjusts the height of the bob. But some bobs have levers or dials to adjust the height. In some precision clocks there is a smaller auxiliary weight on a threaded shaft to allow more fine adjustment. Tower clocks sometimes have a tray mounted on the pendulum rod, to which small weights can be added or removed, to adjust the rate without stopping the clock.

The weight of the bob itself has little effect on the period of the pendulum. However, a heavier bob helps to keep the pendulum moving smoothly until it receives its next push from the clock's escapement mechanism. That increases the pendulum's Q factor, making the motion of the pendulum more independent of the escapement and the errors it introduces, leading to increased accuracy. On the other hand, the heavier the bob is the more energy must be supplied by the clock's power source and more friction and wear occurs in the clock's movement. Pendulum bobs in quality clocks are usually made as heavy as the clock's movement can drive. A common weight for the bob of a one second pendulum, widely used in grandfather clocks and many others, is around 2 kilograms.[ citation needed ]

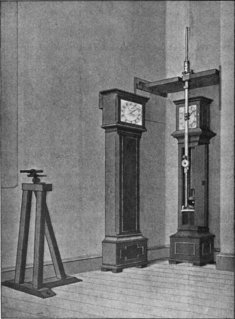

A pendulum clock is a clock that uses a pendulum, a swinging weight, as its timekeeping element. The advantage of a pendulum for timekeeping is that it is a harmonic oscillator: It swings back and forth in a precise time interval dependent on its length, and resists swinging at other rates. From its invention in 1656 by Christiaan Huygens, inspired by Galileo Galilei, until the 1930s, the pendulum clock was the world's most precise timekeeper, accounting for its widespread use. Throughout the 18th and 19th centuries, pendulum clocks in homes, factories, offices, and railroad stations served as primary time standards for scheduling daily life, work shifts, and public transportation. Their greater accuracy allowed for the faster pace of life which was necessary for the Industrial Revolution. The home pendulum clock was replaced by less-expensive, synchronous, electric clocks in the 1930s and '40s. Pendulum clocks are now kept mostly for their decorative and antique value.

A pendulum is a weight suspended from a pivot so that it can swing freely. When a pendulum is displaced sideways from its resting, equilibrium position, it is subject to a restoring force due to gravity that will accelerate it back toward the equilibrium position. When released, the restoring force acting on the pendulum's mass causes it to oscillate about the equilibrium position, swinging back and forth. The time for one complete cycle, a left swing and a right swing, is called the period. The period depends on the length of the pendulum and also to a slight degree on the amplitude, the width of the pendulum's swing.

A Kater's pendulum is a reversible free swinging pendulum invented by British physicist and army captain Henry Kater in 1817 for use as a gravimeter instrument to measure the local acceleration of gravity. Its advantage is that, unlike previous pendulum gravimeters, the pendulum's centre of gravity and center of oscillation do not have to be determined, allowing a greater accuracy. For about a century, until the 1930s, Kater's pendulum and its various refinements remained the standard method for measuring the strength of the Earth's gravity during geodetic surveys. It is now used only for demonstrating pendulum principles.

The gridiron pendulum was a temperature-compensated clock pendulum invented by British clockmaker John Harrison around 1726 and later modified by John Ellicott. It was used in precision clocks. In ordinary clock pendulums, the pendulum rod expands and contracts with changes in temperature. The period of the pendulum's swing depends on its length, so a pendulum clock's rate varied with changes in ambient temperature, causing inaccurate timekeeping. The gridiron pendulum consists of alternating parallel rods of two metals with different thermal expansion coefficients, such as steel and brass. The rods are connected by a frame in such a way that their different thermal expansions compensate for each other, so the overall length of the pendulum, and thus its period, stays constant with temperature.

The grasshopper escapement is a low-friction escapement for pendulum clocks invented by British clockmaker John Harrison around 1722. An escapement, part of every mechanical clock, is the mechanism that gives the clock's pendulum periodic pushes to keep it swinging, and each swing releases the clock's gears to move forward by a fixed amount, thus moving the hands forward at a steady rate. The grasshopper escapement was used in a few regulator clocks built during Harrison's time, and a few others over the years, but has never seen wide use. The term "grasshopper" in this connection, apparently from the kicking action of the pallets, first appears in the Horological Journal in the late 19th century.

An escapement is a mechanical linkage in mechanical watches and clocks that gives impulses to the timekeeping element and periodically releases the gear train to move forward, advancing the clock's hands. The impulse action transfers energy to the clock's timekeeping element to replace the energy lost to friction during its cycle and keep the timekeeper oscillating. The escapement is driven by force from a coiled spring or a suspended weight, transmitted through the timepiece's gear train. Each swing of the pendulum or balance wheel releases a tooth of the escapement's escape wheel, allowing the clock's gear train to advance or "escape" by a fixed amount. This regular periodic advancement moves the clock's hands forward at a steady rate. At the same time, the tooth gives the timekeeping element a push, before another tooth catches on the escapement's pallet, returning the escapement to its "locked" state. The sudden stopping of the escapement's tooth is what generates the characteristic "ticking" sound heard in operating mechanical clocks and watches. The first mechanical escapement, the verge escapement, was invented in medieval Europe during the 13th century, and was the crucial innovation which led to the development of the mechanical clock. The design of the escapement has a large effect on a timepiece's accuracy, and improvements in escapement design drove improvements in time measurement during the era of mechanical timekeeping from the 13th through the 19th century.

A grandfather clock is a tall, freestanding, weight-driven pendulum clock with the pendulum held inside the tower or waist of the case. Clocks of this style are commonly 1.8–2.4 metres (6–8 feet) tall. The case often features elaborately carved ornamentation on the hood, which surrounds and frames the dial, or clock face. The English clockmaker William Clement is credited with the development of this form in 1670. Until the early 20th century, pendulum clocks were the world's most accurate timekeeping technology, and longcase clocks, due to their superior accuracy, served as time standards for households and businesses. Today they are kept mainly for their decorative and antique value, having been widely replaced by both analog and digital timekeeping.

In horology, a movement, also known as a caliber, is the mechanism of a watch or timepiece, as opposed to the case, which encloses and protects the movement, and the face, which displays the time. The term originated with mechanical timepieces, whose clockwork movements are made of many moving parts. The movement of a digital watch is more commonly known as a module.

In horology, the anchor escapement is a type of escapement used in pendulum clocks. The escapement is a mechanism in a mechanical clock that maintains the swing of the pendulum by giving it a small push each swing, and allows the clock's wheels to advance a fixed amount with each swing, moving the clock's hands forward. The anchor escapement was so named because one of its principal parts is shaped vaguely like a ship's anchor.

The vergeescapement is the earliest known type of mechanical escapement, the mechanism in a mechanical clock that controls its rate by allowing the gear train to advance at regular intervals or 'ticks'. Its origin is unknown. Verge escapements were used from the late 13th century until the mid 19th century in clocks and pocketwatches. The name verge comes from the Latin virga, meaning stick or rod.

A coilover is an automobile suspension device. The name coilover is an abbreviation of "coil-over shock absorber".

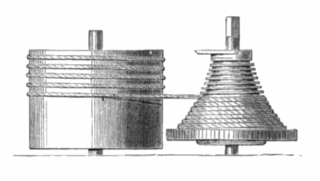

Used in antique spring-powered mechanical watches and clocks, a fusee is a cone-shaped pulley with a helical groove around it, wound with a cord or chain which is attached to the mainspring barrel. Fusees were used from the 15th century to the early 20th century to improve timekeeping by equalizing the uneven pull of the mainspring as it ran down. Gawaine Baillie stated of the fusee, "Perhaps no problem in mechanics has ever been solved so simply and so perfectly."

In an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals.

The Riefler escapement is a mechanical escapement for precision pendulum clocks invented and patented by German instrument maker Sigmund Riefler in 1889. It was used in the astronomical regulator clocks made by his German firm Clemens Riefler from 1890 to 1965, which were perhaps the most accurate all-mechanical pendulum clocks made.

A turret clock or tower clock is a clock designed to be mounted high in the wall of a building, usually in a clock tower, in public buildings such as churches, university buildings, and town halls. As a public amenity to enable the community to tell the time, it has a large face visible from far away, and often a striking mechanism which rings bells upon the hours.

A mechanical watch is a watch that uses a clockwork mechanism to measure the passage of time, as opposed to quartz watches which function electronically via a small battery, or radio watches, which are quartz watches synchronized to an atomic clock via radio waves. A mechanical watch is driven by a mainspring which must be wound either periodically by hand or via a self-winding mechanism. Its force is transmitted through a series of gears to power the balance wheel, a weighted wheel which oscillates back and forth at a constant rate. A device called an escapement releases the watch's wheels to move forward a small amount with each swing of the balance wheel, moving the watch's hands forward at a constant rate. The escapement is what makes the 'ticking' sound which is heard in an operating mechanical watch. Mechanical watches evolved in Europe in the 17th century from spring powered clocks, which appeared in the 15th century.

A marine chronometer is a precision timepiece that is carried on a ship and employed in the determination of the ship's position by celestial navigation. It is used to determine longitude by comparing Greenwich Mean Time (GMT) and the time at the current location found from observations of celestial bodies. When first developed in the 18th century, it was a major technical achievement, as accurate knowledge of the time over a long sea voyage is necessary for navigation, lacking electronic or communications aids. The first true chronometer was the life work of one man, John Harrison, spanning 31 years of persistent experimentation and testing that revolutionized naval navigation and enabling the Age of Discovery and Colonialism to accelerate.

In horology, a wheel train is the gear train of a mechanical watch or clock. Although the term is used for other types of gear trains, the long history of mechanical timepieces has created a traditional terminology for their gear trains which is not used in other applications of gears.

A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Bolts are very closely related to screws.