Related Research Articles

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces.

Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics.

Tin is a chemical element with the symbol Sn and atomic number 50. A silvery-coloured metal, tin is soft enough to be cut with little force, and a bar of tin can be bent by hand with little effort. When bent, the so-called "tin cry" can be heard as a result of twinning in tin crystals; this trait is shared by indium, cadmium, zinc, and mercury in its solid state.

A printed circuit board is a medium used to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with an artwork pattern of traces, planes and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds vias: plated-through holes that allow interconnections between layers.

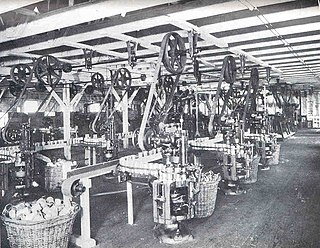

Canning is a method of food preservation in which food is processed and sealed in an airtight container. Canning provides a shelf life that typically ranges from one to five years, although under specific circumstances, it can be much longer. A freeze-dried canned product, such as canned dried lentils, could last as long as 30 years in an edible state.

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced the through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

In metallurgy, a flux is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining.

The Restriction of Hazardous Substances Directive 2002/95/EC, short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Union.

Wave soldering is a bulk soldering process used for the manufacturing of printed circuit boards. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components.

A soldering gun is an approximately pistol-shaped, electrically powered tool for soldering metals using tin-based solder to achieve a strong mechanical bond with good electrical contact. The tool has a trigger-style switch so it can be easily operated with one hand. The body of the tool contains a transformer with a primary winding connected to mains electricity when the trigger is pressed, and a single-turn secondary winding of thick copper with very low resistance. A soldering tip, made of a loop of thinner copper wire, is secured to the end of the transformer secondary by screws, completing the secondary circuit. When the primary of the transformer is energized, several hundred amperes of current flow through the secondary and very rapidly heat the copper tip. Since the tip has a much higher resistance than the rest of the tubular copper winding, the tip gets very hot while the remainder of the secondary warms at a much slower rate. An additional secondary winding is often used to power a pilot lamp which illuminates the workpiece.

Bondo is a polyester putty product originally marketed as an automotive body filler. Nowadays the brand name is used by 3M for a line of American-made products for automotive, marine and household repairs. The term Bondo is trademarked by 3M, but is commonly used to refer to any brand of automotive repair putty due to its popularity. It is also used by sculptors.

A tinsmith is a person who makes and repairs things made of tin or other light metals. The profession may sometimes also be known as a tinner, tinker, tinman, or tinplate worker; whitesmith may also refer to this profession, though the same word may also refer to an unrelated specialty of iron-smithing. By extension it can also refer to the person who deals in tinware, or tin plate. Tinsmith was a common occupation in pre-industrial times.

A filler metal is a metal added in the making of a joint through welding, brazing, or soldering.

A lead sled is a standard production automobile with a body heavily modified in particular ways(see below); especially, though not exclusively, a 1949, 1950, or 1951 model year Ford 'Shoebox' or Mercury Eight car. In the name, "lead" refers to the use of lead as a bodyfiller in early days, and "sled" refers to the lowering of the vehicle, giving these vehicles the appearance that they were "slip sliding" down the highway.

Dip soldering is a small-scale soldering process by which electronic components are soldered to a printed circuit board (PCB) to form an electronic assembly. The solder wets to the exposed metallic areas of the board, creating a reliable mechanical and electrical connection.

Soldering is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint.

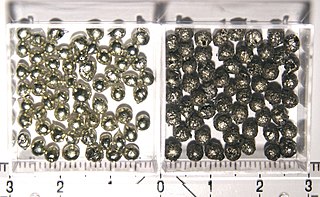

Tin-silver-copper, is a lead-free (Pb-free) alloy commonly used for electronic solder. It is the main choice for lead-free surface-mount technology (SMT) assembly in the industry, as it is near eutectic, with adequate thermal fatigue properties, strength, and wettability. Lead-free solder is gaining much attention as the environmental effects of lead in industrial products is recognized, and as a result of Europe's RoHS legislation to remove lead and other hazardous materials from electronics. Japanese electronics companies have also looked at Pb-free solder for its industrial advantages.

Lead burning is a welding process used to join lead sheet. It is a manual process carried out by gas welding, usually oxy-acetylene.

A wiped joint is a form of soldered joint used to join lead pipework.

References

- ↑ National Research Council (U.S.). Committee on Technical Aspects of Critical and Strategic Materials. (1970), Trends in the use of tin, National Academies, p. 28.