Related Research Articles

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design, integrate, and manage complex systems over their life cycles. At its core, systems engineering utilizes systems thinking principles to organize this body of knowledge. The individual outcome of such efforts, an engineered system, can be defined as a combination of components that work in synergy to collectively perform a useful function.

Computer-Aided Design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used.

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and software programming. A prototype is generally used to evaluate a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one. In some design workflow models, creating a prototype is the step between the formalization and the evaluation of an idea.

An application-specific integrated circuit is an integrated circuit (IC) chip customized for a particular use, rather than intended for general-purpose use, such as a chip designed to run in a digital voice recorder or a high-efficiency video codec. Application-specific standard product chips are intermediate between ASICs and industry standard integrated circuits like the 7400 series or the 4000 series. ASIC chips are typically fabricated using metal–oxide–semiconductor (MOS) technology, as MOS integrated circuit chips.

Software development is the process of conceiving, specifying, designing, programming, documenting, testing, and bug fixing involved in creating and maintaining applications, frameworks, or other software components. Software development involves writing and maintaining the source code, but in a broader sense, it includes all processes from the conception of the desired software through the final manifestation, typically in a planned and structured process often overlapping with software engineering. Software development also includes research, new development, prototyping, modification, reuse, re-engineering, maintenance, or any other activities that result in software products.

Mechatronics engineering also called mechatronics, is an interdisciplinary branch of engineering that focuses on the integration of mechanical, electrical and electronic engineering systems, and also includes a combination of robotics, electronics, computer science, telecommunications, systems, control, and product engineering.

Computer-aided engineering can be defined as the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

In systems engineering and software engineering, requirements analysis focuses on the tasks that determine the needs or conditions to meet the new or altered product or project, taking account of the possibly conflicting requirements of the various stakeholders, analyzing, documenting, validating and managing software or system requirements.

In systems engineering, information systems and software engineering, the systems development life cycle (SDLC), also referred to as the application development life cycle, is a process for planning, creating, testing, and deploying an information system. The SDLC concept applies to a range of hardware and software configurations, as a system can be composed of hardware only, software only, or a combination of both. There are usually six stages in this cycle: requirement analysis, design, development and testing, implementation, documentation, and evaluation.

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprises.

Proof of concept, also known as proof of principle, is a realization of a certain method or idea in order to demonstrate its feasibility, or a demonstration in principle with the aim of verifying that some concept or theory has practical potential. A proof of concept is usually small and may or may not be complete.

In software project management, software testing, and software engineering, verification and validation (V&V) is the process of checking that a software system meets specifications and requirements so that it fulfills its intended purpose. It may also be referred to as software quality control. It is normally the responsibility of software testers as part of the software development lifecycle. In simple terms, software verification is: "Assuming we should build X, does our software achieve its goals without any bugs or gaps?" On the other hand, software validation is: "Was X what we should have built? Does X meet the high-level requirements?"

Software prototyping is the activity of creating prototypes of software applications, i.e., incomplete versions of the software program being developed. It is an activity that can occur in software development and is comparable to prototyping as known from other fields, such as mechanical engineering or manufacturing.

The V-model is a graphical representation of a systems development lifecycle. It is used to produce rigorous development lifecycle models and project management models. The V-model falls into three broad categories, the German V-Modell, a general testing model, and the US government standard.

Integrated circuit design, or IC design, is a sub-field of electronics engineering, encompassing the particular logic and circuit design techniques required to design integrated circuits, or ICs. ICs consist of miniaturized electronic components built into an electrical network on a monolithic semiconductor substrate by photolithography.

The engineering design process, also known as the engineering method, is a common series of steps that engineers use in creating functional products and processes. The process is highly iterative - parts of the process often need to be repeated many times before another can be entered - though the part(s) that get iterated and the number of such cycles in any given project may vary.

Verification and validation are independent procedures that are used together for checking that a product, service, or system meets requirements and specifications and that it fulfills its intended purpose. These are critical components of a quality management system such as ISO 9000. The words "verification" and "validation" are sometimes preceded with "independent", indicating that the verification and validation is to be performed by a disinterested third party. "Integration verification and validation" can be abbreviated as "IV&V".

In software engineering, a software development process is a process of planning and managing software development. It typically involves dividing software development work into smaller, parallel, or sequential steps or sub-processes to improve design and/or product management. It is also known as a software development life cycle (SDLC). The methodology may include the pre-definition of specific deliverables and artifacts that are created and completed by a project team to develop or maintain an application.

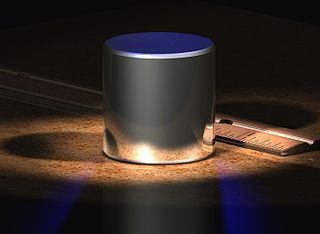

In metrology, a standard is an object, system, or experiment that bears a defined relationship to a unit of measurement of a physical quantity. Standards are the fundamental reference for a system of weights and measures, against which all other measuring devices are compared. Historical standards for length, volume, and mass were defined by many different authorities, which resulted in confusion and inaccuracy of measurements. Modern measurements are defined in relationship to internationally standardized reference objects, which are used under carefully controlled laboratory conditions to define the units of length, mass, electrical potential, and other physical quantities.

Predictive engineering analytics (PEA) is a development approach for the manufacturing industry that helps with the design of complex products. It concerns the introduction of new software tools, the integration between those, and a refinement of simulation and testing processes to improve collaboration between analysis teams that handle different applications. This is combined with intelligent reporting and data analytics. The objective is to let simulation drive the design, to predict product behavior rather than to react on issues which may arise, and to install a process that lets design continue after product delivery.

References

- Hal Mooz, Kevin Forsberg, Howard Cotterman (2003). Communicating project management: the integrated vocabulary of project management and systems engineering . John Wiley and Sons. ISBN 0-471-26924-7.

- Rodney D. Stewart, Ann L. Stewart (1992). Proposal preparation . Wiley-IEEE. ISBN 0-471-55269-0.