Related Research Articles

Cellulose is an organic compound with the formula (C

6H

10O

5)

n, a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

Polyurethane refers to a class of polymers composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from a wide range of starting materials (monomers) and is therefore a class of polymers, rather than a distinct compound. This chemical variety allows for polyurethanes with very different physical properties, leading to an equally wide range of different applications. These include: rigid and flexible foams, varnishes and coatings, adhesives, electrical potting compounds, and fibres such as spandex and PUL. Of these, foams are the largest single application, accounting for 67% of all polyurethane produced in 2016.

Thermal insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials.

In the context of construction, the R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions.

Glass wool is an insulating material made from fibres of glass arranged using a binder into a texture similar to wool. The process traps many small pockets of air between the glass, and these small air pockets result in high thermal insulation properties. Glass wool is produced in rolls or in slabs, with different thermal and mechanical properties. It may also be produced as a material that can be sprayed or applied in place, on the surface to be insulated. The modern method for producing glass wool was invented by Games Slayter while he was working at the Owens-Illinois Glass Co.. He first applied for a patent for a new process to make glass wool in 1933.

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibers, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes.

Fireproofing is rendering something resistant to fire, or incombustible; or material for use in making anything fire-proof. It is a passive fire protection measure. "Fireproof" or "fireproofing" can be used as a noun, verb or adjective; it may be hyphenated ("fire-proof").

Fiberboard or fibreboard is a type of engineered wood product that is made out of wood fibers. Types of fiberboard include particle board or low-density fiberboard (LDF), medium-density fiberboard (MDF), and hardboard.

Nonwoven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

Building insulation is any object in a building used as insulation for thermal management. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation. Often an insulation material will be chosen for its ability to perform several of these functions at once.

A technical textile is a textile product manufactured for non-aesthetic purposes, where function is the primary criterion. Technical textiles include textiles for automotive applications, medical textiles, geotextiles, agrotextiles, and protective clothing.

Building insulation materials are the building materials which form the thermal envelope of a building or otherwise reduce heat transfer.

Wool insulation is made from sheep wool fibres that are either mechanically held together or bonded using between 5% and 20% recycled polyester adhesive to form insulating batts, rolls and ropes. Some companies do not use any adhesives or bonding agents, but rather entangle the wool fibers into in high R-Value, air capturing knops that hold themselves together. Natural wool insulation is effective for both thermal and acoustic insulation. The wool is often sourced from the less expensive black wools of the UK and Europe. Batts are commonly used in the walls and ceilings of timber-frame buildings, rolls can be cut to size for lofts, and ropes can be used between the logs in log homes. Wool knops are installed loosely in attics or in walls as a blow-in-blanket system utilizing a fiber mesh to hold the wool in place during the blow in process.

The word cellulose comes from the French word cellule for a living cell and glucose which is a sugar. Building insulation is low-thermal-conductivity material used to reduce building heat loss and gain and reduce noise transmission. Cellulose insulation is plant fiber used in wall and roof cavities to insulate, draught proof and reduce free noise.

Rigid panel insulation, also referred to as continuous insulation, can be made from foam plastics such as polyurethane (PUR), polyisocyanurate (PIR), and polystyrene, or from fibrous materials such as fiberglass, rock and slag wool. Rigid panel continuous insulation is often used to provide a thermal break in the building envelope, thus reducing thermal bridging.

4,4′-Oxydianiline is an organic compound with the formula O(C6H4NH2)2. It is an ether derivative of aniline. This colourless solid is a useful monomer and cross-linking agent for polymers, especially the polyimides, such as Kapton.

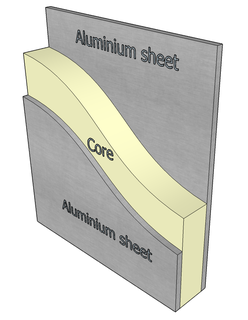

A sandwich panel is any structure made of three layers: a low-density core, and a thin skin-layer bonded to each side. Sandwich panels are used in applications where a combination of high structural rigidity and low weight is required.

Wet process engineering is one of the major streams in textile engineering which refers to the engineering of textile chemical processes and associated applied science. The other three streams in textile engineering are yarn engineering, fabric engineering, and apparel engineering. The processes of this stream are involved or carried out in an aqueous stage. Hence, it is called a wet process which usually covers pre-treatment, dyeing, printing, and finishing.

Coex is a biopolymer with flame-retardant properties derived from the functionalization of cellulosic fibers such as cotton, linen, jute, cannabis, coconut, ramie, bamboo, raffia palm, stipa, abacà, sisal, nettle and kapok. The treatment effectiveness was also proven on wood and semi-synthetic fibers such as cellulose acetate, cellulose triacetate, viscose, modal, lyocell and cupro.

Hemp paper means paper varieties consisting exclusively or to a large extent from pulp obtained from fibers of industrial hemp. The products are mainly specialty papers such as cigarette paper, banknotes and technical filter papers. Compared to wood pulp, hemp pulp offers a four to five times longer fibre, a significantly lower lignin fraction as well as a higher tear resistance and tensile strength. Because the paper industry's processes have been optimized for wood as the feedstock, production costs currently are much higher than for paper from wood.

References

- ↑ "Comparison between Cellulose Insulation and Fiberglass Insulation" . Retrieved 2017-12-20.