In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Such a standard could be another measurement device of known accuracy, a device generating the quantity to be measured such as a voltage, a sound tone, or a physical artifact, such as a meter ruler.

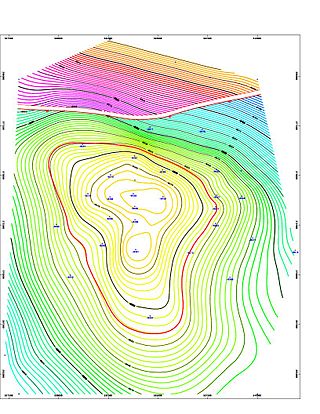

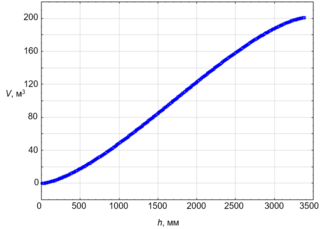

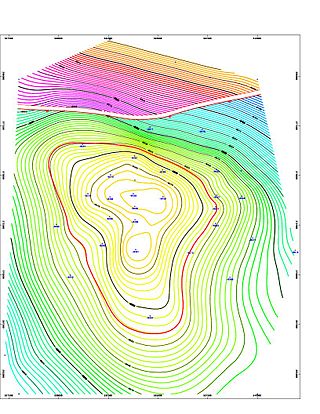

Petroleum engineering is a field of engineering concerned with the activities related to the production of hydrocarbons, which can be either crude oil or natural gas. Exploration and production are deemed to fall within the upstream sector of the oil and gas industry. Exploration, by earth scientists, and petroleum engineering are the oil and gas industry's two main subsurface disciplines, which focus on maximizing economic recovery of hydrocarbons from subsurface reservoirs. Petroleum geology and geophysics focus on provision of a static description of the hydrocarbon reservoir rock, while petroleum engineering focuses on estimation of the recoverable volume of this resource using a detailed understanding of the physical behavior of oil, water and gas within porous rock at very high pressure.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

A wet gas is any gas with a small amount of liquid present. The term "wet gas" has been used to describe a range of conditions varying from a humid gas which is gas saturated with liquid vapour to a multiphase flow with a 90% volume of gas. There has been some debate as to its actual definition, and there is currently no fully defined quantitative definition of a wet gas flow that is universally accepted.

Petrophysics is the study of physical and chemical rock properties and their interactions with fluids.

Moisture analysis covers a variety of methods for measuring the moisture content in solids, liquids, or gases. For example, moisture is a common specification in commercial food production. There are many applications where trace moisture measurements are necessary for manufacturing and process quality assurance. Trace moisture in solids must be known in processes involving plastics, pharmaceuticals and heat treatment. Fields that require moisture measurement in gasses or liquids include hydrocarbon processing, pure semiconductor gases, bulk pure or mixed gases, dielectric gases such as those in transformers and power plants, and natural gas pipeline transport. Moisture content measurements can be reported in multiple units, such as: parts per million, pounds of water per million standard cubic feet of gas, mass of water vapor per unit volume or mass of water vapor per unit mass of dry gas.

The hydrocarbon dew point is the temperature at which the hydrocarbon components of any hydrocarbon-rich gas mixture, such as natural gas, will start to condense out of the gaseous phase. It is often also referred to as the HDP or the HCDP. The maximum temperature at which such condensation takes place is called the cricondentherm. The hydrocarbon dew point is a function of the gas composition as well as the pressure.

A multiphase flow meter is a device used to measure the individual phase flow rates of constituent phases in a given flow where oil, water and gas mixtures are initially co-mingled together during the oil production processes.

An oil production plant is a facility which processes production fluids from oil wells in order to separate out key components and prepare them for export. Typical oil well production fluids are a mixture of oil, gas and produced water. An oil production plant is distinct from an oil depot, which does not have processing facilities.

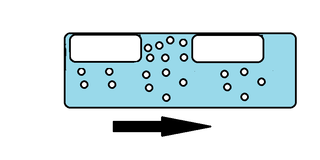

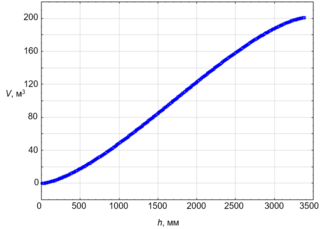

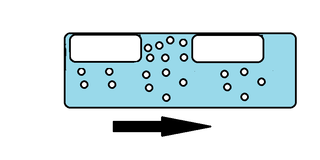

The term separator in oilfield terminology designates a pressure vessel used for separating well fluids produced from oil and gas wells into gaseous and liquid components. A separator for petroleum production is a large vessel designed to separate production fluids into their constituent components of oil, gas and water. A separating vessel may be referred to in the following ways: Oil and gas separator, Separator, Stage separator, Trap, Knockout vessel, Flash chamber, Expansion separator or expansion vessel, Scrubber, Filter. These separating vessels are normally used on a producing lease or platform near the wellhead, manifold, or tank battery to separate fluids produced from oil and gas wells into oil and gas or liquid and gas. An oil and gas separator generally includes the following essential components and features:

- A vessel that includes (a) primary separation device and/or section, (b) secondary "gravity" settling (separating) section, (c) mist extractor to remove small liquid particles from the gas, (d) gas outlet, (e) liquid settling (separating) section to remove gas or vapor from oil, (f) oil outlet, and (g) water outlet.

- Adequate volumetric liquid capacity to handle liquid surges (slugs) from the wells and/or flowlines.

- Adequate vessel diameter and height or length to allow most of the liquid to separate from the gas so that the mist extractor will not be flooded.

- A means of controlling an oil level in the separator, which usually includes a liquid-level controller and a diaphragm motor valve on the oil outlet.

- A back pressure valve on the gas outlet to maintain a steady pressure in the vessel.

- Pressure relief devices.

Custody Transfer in the oil and gas industry refers to the transactions involving transporting physical substance from one operator to another. This includes the transferring of raw and refined petroleum between tanks and railway tank cars; onto ships, and other transactions. Custody transfer in fluid measurement is defined as a metering point (location) where the fluid is being measured for sale from one party to another. During custody transfer, accuracy is of great importance to both the company delivering the material and the eventual recipient, when transferring a material.

Fred F. Meissner was an American geologist and engineer who contributed to the fields of geology, geophysics, engineering, petroleum engineering, geochemistry, mineralogy, physics, mining, economic geology, and fishing.

Alden Research Laboratory, Inc. (Alden) was founded in 1894 as part of Worcester Polytechnic Institute (WPI). It is the oldest continuously operating hydraulic laboratory in the United States. Today, as an independent entity, Alden has become a recognized leader in the field of fluid dynamics research and development.

Instrumentation is used to monitor and control the process plant in the oil, gas and petrochemical industries. Instrumentation ensures that the plant operates within defined parameters to produce materials of consistent quality and within the required specifications. It also ensures that the plant is operated safely and acts to correct out of tolerance operation and to automatically shut down the plant to prevent hazardous conditions from occurring. Instrumentation comprises sensor elements, signal transmitters, controllers, indicators and alarms, actuated valves, logic circuits and operator interfaces.

Flow conditioning ensures that the "real world" environment closely resembles the "laboratory" environment for proper performance of inferential flowmeters like orifice, turbine, coriolis, ultrasonic etc.

In the petroleum industry, a well test is the execution of a set of planned data acquisition activities. The acquired data is analyzed to broaden the knowledge and increase the understanding of the hydrocarbon properties therein and characteristics of the underground reservoir where the hydrocarbons are trapped.

In the petroleum industry, allocation refers to practices of breaking down measures of quantities of extracted hydrocarbons across various contributing sources. Allocation aids the attribution of ownerships of hydrocarbons as each contributing element to a commingled flow or to a storage of petroleum may have a unique ownership. Contributing sources in this context are typically producing petroleum wells delivering flows of petroleum or flows of natural gas to a commingled flow or storage.

In fluid mechanics, slug flow in liquid–gas two-phase flow is a type of flow pattern. Lighter, faster moving continuous fluid which contains gas bubbles - pushes along a disperse gas bubble. Pressure oscillations within piping can be caused by slug flow. The word slug usually refers to the heavier, slower moving fluid, but can also be used to refer to the bubbles of the lighter fluid.

Marcia Lynn Huber is an American chemical engineer. She is a researcher at the National Institute of Standards and Technology. Huber's research interests include developing models for the thermophysical properties of fluids. She was awarded the Department of Commerce Bronze Medal in 2005.