A wire is a flexible, round, bar of metal.

In electrical engineering, ground or earth may be a reference point in an electrical circuit from which voltages are measured, a common return path for electric current, or a direct physical connection to the Earth.

Coaxial cable, or coax, is a type of electrical cable consisting of an inner conductor surrounded by a concentric conducting shield, with the two separated by a dielectric ; many coaxial cables also have a protective outer sheath or jacket. The term coaxial refers to the inner conductor and the outer shield sharing a geometric axis.

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze, and spring copper, is a copper alloy with 0.5–3% beryllium. Copper beryllium alloys are often used because of their high strength and good conductivity of both heat and electricity. It is used for its ductility, weldability in metalworking, and machining properties. It has many specialized applications in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and some uses in the field of aerospace. Beryllium copper and other beryllium alloys are harmful carcinogens that present a toxic inhalation hazard during manufacturing.

Cupronickel or copper–nickel (CuNi) is an alloy of copper with nickel, usually along with small quantities of other elements added for strength, such as iron and manganese. The copper content typically varies from 60 to 90 percent.

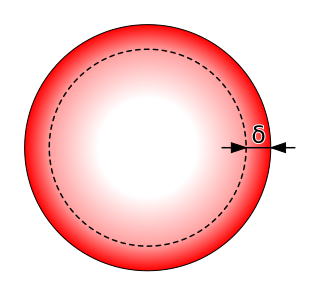

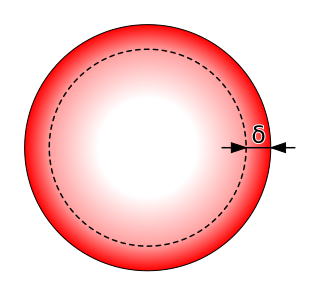

In electromagnetism, skin effect is the tendency of an alternating electric current (AC) to become distributed within a conductor such that the current density is largest near the surface of the conductor and decreases exponentially with greater depths in the conductor. It is caused by opposing eddy currents induced by the changing magnetic field resulting from the alternating current. The electric current flows mainly at the skin of the conductor, between the outer surface and a level called the skin depth. Skin depth depends on the frequency of the alternating current; as frequency increases, current flow becomes more concentrated near the surface, resulting in less skin depth. Skin effect reduces the effective cross-section of the conductor and thus increases its effective resistance. At 60 Hz in copper, skin depth is about 8.5 mm. At high frequencies, skin depth becomes much smaller.

Twin-lead cable is a two-conductor flat cable used as a balanced transmission line to carry radio frequency (RF) signals. It is constructed of two stranded or solid copper or copper-clad steel wires, held a precise distance apart by a plastic ribbon. The uniform spacing of the wires is the key to the cable's function as a transmission line; any abrupt changes in spacing would reflect some of the signal back toward the source. The plastic also covers and insulates the wires. It is available with several different values of characteristic impedance, the most common type is 300 ohm.

The F connector is a coaxial RF connector commonly used for "over the air" terrestrial television, cable television and universally for satellite television and cable modems, usually with RG-6/U cable or with RG-59/U cable.

A mast radiator is a radio mast or tower in which the metal structure itself is energized and functions as an antenna. This design, first used widely in the 1930s, is commonly used for transmitting antennas operating at low frequencies, in the LF and MF bands, in particular those used for AM radio broadcasting stations. The conductive steel mast is electrically connected to the transmitter. Its base is usually mounted on a nonconductive support to insulate it from the ground. A mast radiator is a form of monopole antenna.

An earthing system or grounding system (US) connects specific parts of an electric power system with the ground, typically the Earth's conductive surface, for safety and functional purposes. The choice of earthing system can affect the safety and electromagnetic compatibility of the installation. Regulations for earthing systems vary among countries, though most follow the recommendations of the International Electrotechnical Commission (IEC). Regulations may identify special cases for earthing in mines, in patient care areas, or in hazardous areas of industrial plants.

A groundbed is an array of electrodes, installed in the ground to provide a low resistance electrical path to ground or earth. A groundbed is a component in an earthing system.

A radio transmitter or receiver is connected to an antenna which emits or receives the radio waves. The antenna feed system or antenna feed is the cable or conductor, and other associated equipment, which connects the transmitter or receiver with the antenna and makes the two devices compatible. In a radio transmitter, the transmitter generates an alternating current of radio frequency, and the feed system feeds the current to the antenna, which converts the power in the current to radio waves. In a radio receiver, the incoming radio waves excite tiny alternating currents in the antenna, and the feed system delivers this current to the receiver, which processes the signal.

Copper-clad aluminium wire is a dual-metal electrical conductor composed of an inner aluminium core and outer copper cladding.

RG-6/U is a common type of coaxial cable used in a wide variety of residential and commercial applications. An RG-6/U coaxial cable has a characteristic impedance of 75 ohms. The term, RG-6, is generic and is applied to a wide variety of cable designs, which differ from one another in shielding characteristics, center conductor composition, dielectric type and jacket type. RG was originally a unit indicator for bulk radio frequency (RF) cable in the U.S. military's Joint Electronics Type Designation System. The suffix /U means for general utility use. The number was assigned sequentially. The RG unit indicator is no longer part of the JETDS system (MIL-STD-196E) and cable sold today under the RG-6 label is unlikely to meet military specifications. In practice, the term RG-6 is generally used to refer to coaxial cables with an 18 AWG center conductor and 75 ohm characteristic impedance.

Exothermic welding, also known as exothermic bonding, thermite welding (TW), and thermit welding, is a welding process that employs molten metal to permanently join the conductors. The process employs an exothermic reaction of a thermite composition to heat the metal, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminium powder and a metal oxide.

Aluminium conductor steel-reinforced cable (ACSR) is a type of high-capacity, high-strength stranded conductor typically used in overhead power lines. The outer strands are high-purity aluminium, chosen for its good conductivity, low weight, low cost, resistance to corrosion and decent mechanical stress resistance. The centre strand is steel for additional strength to help support the weight of the conductor. Steel is of higher strength than aluminium which allows for increased mechanical tension to be applied on the conductor. Steel also has lower elastic and inelastic deformation due to mechanical loading as well as a lower coefficient of thermal expansion under current loading. These properties allow ACSR to sag significantly less than all-aluminium conductors. As per the International Electrotechnical Commission (IEC) and The CSA Group naming convention, ACSR is designated A1/S1A.

Glass-to-metal seals are a type of mechanical seal which joins glass and metal surfaces. They are very important elements in the construction of vacuum tubes, electric discharge tubes, incandescent light bulbs, glass-encapsulated semiconductor diodes, reed switches, glass windows in metal cases, and metal or ceramic packages of electronic components.

Copper has been used in electrical wiring since the invention of the electromagnet and the telegraph in the 1820s. The invention of the telephone in 1876 created further demand for copper wire as an electrical conductor.

A metal hose is a flexible metal line element. There are two basic types of metal hose that differ in their design and application: stripwound hoses and corrugated hoses.

An electrical conduit is a tube used to protect and route electrical wiring in a building or structure. Electrical conduit may be made of metal, plastic, fiber, or fired clay. Most conduit is rigid, but flexible conduit is used for some purposes.