A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing and to transform many other materials.

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

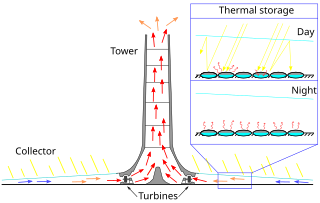

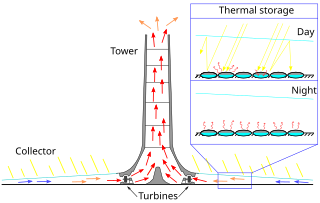

The solar updraft tower (SUT) is a design concept for a renewable-energy power plant for generating electricity from low temperature solar heat. Sunshine heats the air beneath a very wide greenhouse-like roofed collector structure surrounding the central base of a very tall chimney tower. The resulting convection causes a hot air updraft in the tower by the chimney effect. This airflow drives wind turbines, placed in the chimney updraft or around the chimney base, to produce electricity.

A chimney is an architectural ventilation structure made of masonry, clay or metal that isolates hot toxic exhaust gases or smoke produced by a boiler, stove, furnace, incinerator, or fireplace from human living areas. Chimneys are typically vertical, or as near as possible to vertical, to ensure that the gases flow smoothly, drawing air into the combustion in what is known as the stack, or chimney effect. The space inside a chimney is called the flue. Chimneys are adjacent to large industrial refineries, fossil fuel combustion facilities or part of buildings, steam locomotives and ships.

The Franklin stove is a metal-lined fireplace named after Benjamin Franklin, who invented it in 1743. It had a hollow baffle near the rear and relied on an "inverted siphon" to draw the fire's hot fumes around the baffle. It was intended to produce more heat and less smoke than an ordinary open fireplace, but it achieved few sales until it was improved by David Rittenhouse. It is also known as a "circulating stove" or the "Pennsylvania fireplace".

A stove or range is a device that generates heat inside or on top of the device, for local heating or cooking. Stoves can be powered with many fuels, such as electricity, natural gas, gasoline, wood, and coal.

An oast, oast house or hop kiln is a building designed for kilning (drying) hops as part of the brewing process. They can be found in most hop-growing areas and are often good examples of vernacular architecture. Many redundant oasts have been converted into houses. The names oast and oast house are used interchangeably in Kent and Sussex. In Surrey, Hampshire, Herefordshire and Worcestershire they are called hop kilns.

A fireplace or hearth is a structure made of brick, stone or metal designed to contain a fire. Fireplaces are used for the relaxing ambiance they create and for heating a room. Modern fireplaces vary in heat efficiency, depending on the design.

The Rumford fireplace is a tall, shallow fireplace designed by Sir Benjamin Thompson, Count Rumford, an Anglo-American physicist best known for his investigations of heat. Its shallow, angled sides are designed to reflect heat into the room, and its streamlined throat minimizes turbulence, thereby carrying away smoke with little loss of heated room air.

A smudge pot is an oil-burning device used to prevent frost on fruit trees. Usually a smudge pot has a large round base with a chimney coming out of the middle of the base. The smudge pot is placed between trees in an orchard. The burning oil creates heat, smoke, carbon dioxide, and water vapor. It was believed that this oil burning heater would help keep the orchard from cooling too much during the cold snaps.

A flue is a duct, pipe, or opening in a chimney for conveying exhaust gases from a fireplace, furnace, water heater, boiler, or generator to the outdoors. Historically the term flue meant the chimney itself. In the United States, they are also known as vents for boilers and as breeching for water heaters and modern furnaces. They usually operate by buoyancy, also known as the stack effect, or the combustion products may be 'induced' via a blower. As combustion products contain carbon monoxide and other dangerous compounds, proper 'draft', and admission of replacement air is imperative. Building codes, and other standards, regulate their materials, design, and installation.

The anagamakiln is an ancient type of pottery kiln brought to Japan from China via Korea in the 5th century. It is a version of the climbing dragon kiln of south China, whose further development was also copied, for example in breaking up the firing space into a series of chambers in the noborigama kiln.

A masonry heater is a device for warming an interior space through radiant heating, by capturing the heat from periodic burning of fuel, and then radiating the heat at a fairly constant temperature for a long period. Masonry heaters covered in tile are called cocklestoves. The technology has existed in different forms, from back into the Neoglacial and Neolithic periods. Archaeological digs have revealed excavations of ancient inhabitants utilizing hot smoke from fires in their subterranean dwellings, to radiate into the living spaces. These early forms have evolved into modern systems.

The stack effect or chimney effect is the movement of air into and out of buildings through unsealed openings, chimneys, flue-gas stacks, or other containers, resulting from air buoyancy. Buoyancy occurs due to a difference in indoor-to-outdoor air density resulting from temperature and moisture differences. The result is either a positive or negative buoyancy force. The greater the thermal difference and the height of the structure, the greater the buoyancy force, and thus the stack effect. The stack effect helps drive natural ventilation, air infiltration, and fires.

A flue-gas stack, also known as a smoke stack, chimney stack or simply as a stack, is a type of chimney, a vertical pipe, channel or similar structure through, which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power plant's steam-generating boiler, or other large combustion device. Flue gas is usually composed of carbon dioxide (CO2) and water vapor, as well as nitrogen and excess oxygen remaining from the intake combustion air. It also contains a small percentage of pollutants such as particulate matter, carbon monoxide, nitrogen oxides and sulfur oxides. The flue gas stacks are often quite tall, up to 420 metres (1,380 ft), to increase the stack effect and dispersion of pollutants.

A chimney fire is the combustion (burning) of residue deposits referred to as soot or creosote, on the inner surfaces of chimney tiles, flue liners, stove pipes, etc.

The lò trấu is a type of versatile fuel burning cook stove used in Vietnam since the 1950s. Lò trấu comes from lò (stove) and trấu. A kitchen with this kind of stove is a bếp trấu, "husk kitchen."

A wood-burning stove is a heating or cooking appliance capable of burning wood fuel, often called solid fuel, and wood-derived biomass fuel, such as sawdust bricks. Generally the appliance consists of a solid metal closed firebox, often lined by fire brick, and one or more air controls. The first wood-burning stove was patented in Strasbourg in 1557. This was two centuries before the Industrial Revolution, so iron was still prohibitively expensive. The first wood-burning stoves were high-end consumer items and only gradually became used widely.

A bottle oven or bottle kiln is a type of kiln. The word 'bottle' refers to the shape of the structure and not to the kiln's products, which are usually pottery, not glass.