Mining is the extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. The ore must be a rock or mineral that contains valuable constituent, can be extracted or mined and sold for profit. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water.

Ore is natural rock or sediment that contains one or more valuable minerals concentrated above background levels, typically containing metals, that can be mined, treated and sold at a profit. The grade of ore refers to the concentration of the desired material it contains. The value of the metals or minerals a rock contains must be weighed against the cost of extraction to determine whether it is of sufficiently high grade to be worth mining and is therefore considered an ore. A complex ore is one containing more than one valuable mineral.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe

3O

4, 72.4% Fe), hematite (Fe

2O

3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H2O), 55% Fe), or siderite (FeCO3, 48.2% Fe).

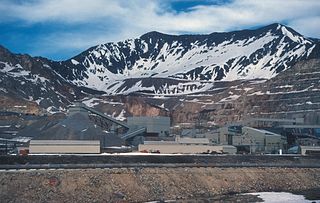

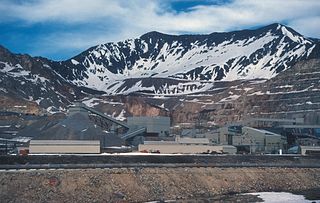

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique that extracts rock or minerals from the earth.

A non-renewable resource is a natural resource that cannot be readily replaced by natural means at a pace quick enough to keep up with consumption. An example is carbon-based fossil fuels. The original organic matter, with the aid of heat and pressure, becomes a fuel such as oil or gas. Earth minerals and metal ores, fossil fuels and groundwater in certain aquifers are all considered non-renewable resources, though individual elements are always conserved.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

Scrap consists of recyclable materials, usually metals, left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered metals, and non-metallic materials are also recovered for recycling. Once collected, the materials are sorted into types – typically metal scrap will be crushed, shredded, and sorted using mechanical processes.

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century. It has been described as "the single most important operation used for the recovery and upgrading of sulfide ores". The development of froth flotation has improved the recovery of valuable minerals, such as copper- and lead-bearing minerals. Along with mechanized mining, it has allowed the economic recovery of valuable metals from much lower-grade ore than previously.

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.

Silver mining is the extraction of silver by mining. Silver is a precious metal and holds high economic value. Because silver is often found in intimate combination with other metals, its extraction requires the use of complex technologies. In 2008, approximately 25,900 metric tons of silver were consumed worldwide, most of which came from mining. Silver mining has a variety of effects on the environment, humans, and animals.

Biomining refers to any process that uses living organisms to extract metals from ores and other solid materials. Typically these processes involve prokaryotes, however fungi and plants may also be used. Biomining is one of several applications within biohydrometallurgy with applications in ore refinement, precious metal recovery, and bioremediation. The largest application currently being used is the treatment of mining waste containing iron, copper, zinc, and gold allowing for salvation of any discarded minerals. It may also be useful in maximizing the yields of increasingly low grade ore deposits. Biomining has been proposed as a relatively environmentally friendly alternative and/or supplementation to traditional mining. Current methods of biomining are modified leach mining processes. These aptly named bioleaching processes most commonly includes the inoculation of extracted rock with bacteria and acidic solution, with the leachate salvaged and processed for the metals of value. Biomining has many applications outside of metal recovery, most notably is bioremediation which has already been used to clean up coastlines after oil spills. There are also many promising future applications, like space biomining, fungal bioleaching and biomining with hybrid biomaterials.

The Red Dog mine is a large zinc and lead mine in a remote region of Alaska, about 80 miles (130 km) north of Kotzebue, which is operated by the Canadian mining company Teck Resources on land owned by the NANA Regional Corporation. It is located within the boundaries of the Red Dog Mine census-designated place in the Northwest Arctic Borough of the U.S. state of Alaska.

Natural resource economics deals with the supply, demand, and allocation of the Earth's natural resources. One main objective of natural resource economics is to better understand the role of natural resources in the economy in order to develop more sustainable methods of managing those resources to ensure their availability for future generations. Resource economists study interactions between economic and natural systems, with the goal of developing a sustainable and efficient economy.

The Climax mine, located in Climax, Colorado, United States, is a major molybdenum mine in Lake and Summit counties, Colorado. Shipments from the mine began in 1915. At its highest output, the Climax mine was the largest molybdenum mine in the world, and for many years it supplied three quarters of the world's supply of molybdenum.

Peak minerals marks the point in time when the largest production of a mineral will occur in an area, with production declining in subsequent years. While most mineral resources will not be exhausted in the near future, global extraction and production has become more challenging. Miners have found ways over time to extract deeper and lower grade ores with lower production costs. More than anything else, declining average ore grades are indicative of ongoing technological shifts that have enabled inclusion of more 'complex' processing – in social and environmental terms as well as economic – and structural changes in the minerals exploration industry and these have been accompanied by significant increases in identified Mineral Reserves.

Mobile phone recycling describes the waste management of mobile phones, to retrieve materials used in their manufacture. Rapid technology change, low initial cost, and planned obsolescence have resulted in a fast-growing surplus, which contributes to the increasing amount of electronic waste around the globe.

Sensor-based sorting, is an umbrella term for all applications in which particles are detected using a sensor technique and rejected by an amplified mechanical, hydraulic or pneumatic process.

Mining in North Korea is important to the country's economy. North Korea is naturally abundant in metals such as magnesite, zinc, tungsten, and iron; with magnesite resources of 6 billion tonnes, particularly in the North and South Hamgyong Province and Chagang Province. However, often these cannot be mined due to the acute shortage of electricity in the country, as well as the lack of proper tools to mine these materials and an antiquated industrial base. Coal, iron ore, limestone, and magnesite deposits are larger than other mineral commodities. Mining joint ventures with other countries include China, Canada, Egypt, and South Korea.

Mineral resource estimation is used to determine and define the ore tonnage and grade of a geological deposit, from the developed block model. There are different estimation methods used for different scenarios dependent upon the ore boundaries, geological deposit geometry, grade variability and the amount of time and money available. A typical resource estimation involves the construction of a geological and resource model with data from various sources. Depending on the nature of the information and whether the data is hard copy or computerized, the principal steps of computer resource estimation are:

- Creation, standardization and validation of the database.

- Section plotting and interactive geological modeling.

- Geostatistical analysis.

- Block modeling and block estimation.