A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal, or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it.

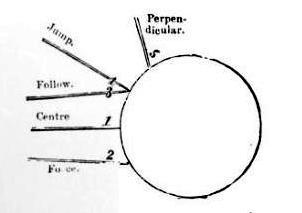

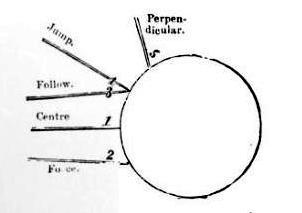

In archaeology, a lithic flake is a "portion of rock removed from an objective piece by percussion or pressure," and may also be referred to as simply a flake, or collectively as debitage. The objective piece, or the rock being reduced by the removal of flakes, is known as a core. Once the proper tool stone has been selected, a percussor or pressure flaker is used to direct a sharp blow, or apply sufficient force, respectively, to the surface of the stone, often on the edge of the piece. The energy of this blow propagates through the material, often producing a Hertzian cone of force which causes the rock to fracture in a controllable fashion. Since cores are often struck on an edge with a suitable angle (<90°) for flake propagation, the result is that only a portion of the Hertzian cone is created. The process continues as the flintknapper detaches the desired number of flakes from the core, which is marked with the negative scars of these removals. The surface area of the core which received the blows necessary for detaching the flakes is referred to as the striking platform.

In lithic analysis, a subdivision of archaeology, a bulb of applied force is a defining characteristic of a lithic flake. Bulb of applied force was first correctly described by Sir John Evans, the cofounder of prehistoric archeology. However, bulb of percussion was coined scientifically by W.J. Sollas. When a flake is detached from its parent core, a portion of the Hertzian cone of force caused by the detachment blow is detached with it, leaving a distinctive bulb on the flake and a corresponding flake scar on the core. In the case of a unidirectional core, the bulb of applied force is produced by an initiated crack formed at the point of contact, which begins producing the Hertzian cone. The outward pressure increases causing the crack to curve away from the core and the bulb formation. The bulb of applied force forms below the striking platform as a slight bulge. If the flake is completely crushed the bulb will not be visible. Bulbs of applied force may be distinctive, moderate, or diffuse, depending upon the force of the blow used to detach the flake, and upon the type of material used as a fabricator. The bulb of applied force can indicate the mass or density of the tool used in the application of the force. The bulb may also be an indication of the angle of the force. This information is helpful to archaeologists in understanding and recreating the process of flintknapping. Generally, the harder the material used as a fabricator, the more distinctive the bulb of applied force. Soft hammer percussion has a low diffuse bulb while hard hammer percussion usually leaves a more distinct and noticeable bulb of applied force. Pressure flake also allowed for diffuse bulbs. The bulb of percussion of a flake or blade is convex and the core has a corresponding concave bulb. The concave bulb on the core is known as the negative bulb of percussion. Bulbs of applied force are not usually present if the flake has been struck off naturally. This allows archaeologists to identify and distinguish natural breakage from human artistry. The three main bulb types are flat or nondescript, normal, and pronounced. A flat or nondescript bulb is poorly defined and does not rise up on the ventral surface. A normal bulb on the ventral side has average height and well-defined. A pronounced bulb rises up on ventral side and is very large.

Marble has been the preferred material for stone monumental sculpture since ancient times, with several advantages over its more common geological "parent" limestone, in particular the ability to absorb light a small distance into the surface before refracting it in subsurface scattering. This gives an attractive soft appearance that is especially good for representing human skin, which can also be polished.

An anvil is a metalworking tool consisting of a large block of metal, with a flattened top surface, upon which another object is struck.

A splitting maul also known as a block buster, block splitter, chop and maul, sledge axe, go-devil or hamaxe is a heavy, long-handled axe used for splitting a piece of wood along its grain. One side of its head is like a sledgehammer, and the other side is like an axe.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the tail. On installation, the rivet is placed in a punched or drilled hole, and the tail is upset, or bucked, so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the factory head and the deformed end is called the shop head or buck-tail.

A strike is a directed physical attack with either a part of the human body or with an inanimate object intended to cause blunt trauma or penetrating trauma upon an opponent.

A mallet is a tool used for imparting force on another object, often made of rubber or sometimes wood, that is smaller than a maul or beetle, and usually has a relatively large head. The term is descriptive of the overall size and proportions of the tool, and not the materials it may be made of, though most mallets have striking faces that are softer than steel.

A froe, shake axe or paling knife is a tool for cleaving wood by splitting it along the grain. It is an L-shaped tool, used by hammering one edge of its blade into the end of a piece of wood in the direction of the grain, then twisting the blade in the wood by rotating the haft (handle).

In metalworking, a drift pin, drift pin punch, simply drift, is the name for a tool used for localizing a hammer blow. A drift is smaller in diameter than the hammer face, thus concentrating the force into a smaller area. A drift is also used where the surrounding surfaces need to be protected from the hammer blow.

Metalworking hand tools are hand tools that are used in the metalworking field. Hand tools are powered solely by the operator.

Pneumatic cylinders are mechanical devices which use the power of compressed gas to produce a force in a reciprocating linear motion.

Cue sports techniques are a vital important aspect of game play in the various cue sports such as carom billiards, pool, snooker and other games. Such techniques are used on each shot in an attempt to achieve an immediate aim such as scoring or playing a safety, while at the same time exercising control over the positioning of the cue ball and often the object balls for the next shot or inning.

The earthquake bomb, or seismic bomb, was a concept that was invented by the British aeronautical engineer Barnes Wallis early in World War II and subsequently developed and used during the war against strategic targets in Europe. A seismic bomb differs somewhat in concept from traditional bombs, which usually explode at or near the surface, and destroy their target directly by explosive force. In contrast, a seismic bomb is dropped from high altitude to attain very high speed as it falls and upon impact, penetrates and explodes deep underground, causing massive caverns or craters known as camouflets, as well as intense shockwaves. In this way, the seismic bomb can affect targets that are too massive to be affected by a conventional bomb, as well as damage or destroy difficult targets such as bridges and viaducts.

A punch is a tool used to indent or create a hole through a hard surface. They usually consist of a hard metal rod with a narrow tip at one end and a broad flat "butt" at the other. When used, the narrower end is pointed against a target surface and the broad end is then struck with a hammer or mallet, causing the blunt force of the blow to be transmitted down the rod body and focused more sharply onto a small area. Typically, woodworkers use a ball-peen hammer to strike a punch.

A slide hammer is a tool that attaches to an object needing to be pulled and transmits an impact force to the object without striking the object itself.

A soft-faced hammer or mallet is a hammer designed to offer driving force without damaging surfaces. They also reduce the force transmitted back to the arm or hand of the user, by temporarily deforming more than a metal hammer would.