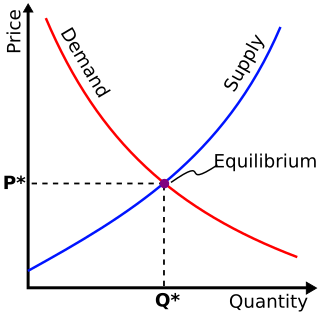

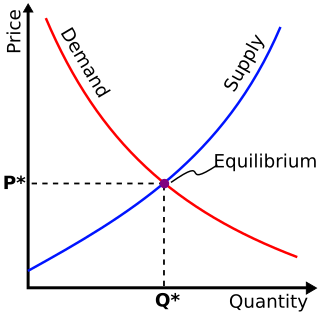

Microeconomics is a branch of economics that studies the behavior of individuals and firms in making decisions regarding the allocation of scarce resources and the interactions among these individuals and firms. Microeconomics focuses on the study of individual markets, sectors, or industries as opposed to the economy as a whole, which is studied in macroeconomics.

Unobtainium is a term used in fiction, engineering, and common situations for a material ideal for a particular application but impractically difficult or impossible to obtain. Unobtainium originally referred to materials that do not exist at all, but can also be used to describe real materials that are unavailable due to extreme rarity or cost. Less commonly, it can mean a device with desirable engineering properties for an application that are exceedingly difficult or impossible to achieve.

Cost accounting is defined by the Institute of Management Accountants as "a systematic set of procedures for recording and reporting measurements of the cost of manufacturing goods and performing services in the aggregate and in detail. It includes methods for recognizing, allocating, aggregating and reporting such costs and comparing them with standard costs". Often considered a subset of managerial accounting, its end goal is to advise the management on how to optimize business practices and processes based on cost efficiency and capability. Cost accounting provides the detailed cost information that management needs to control current operations and plan for the future.

In management accounting or managerial accounting, managers use accounting information in decision-making and to assist in the management and performance of their control functions.

In economics, profit maximization is the short run or long run process by which a firm may determine the price, input and output levels that will lead to the highest possible total profit. In neoclassical economics, which is currently the mainstream approach to microeconomics, the firm is assumed to be a "rational agent" which wants to maximize its total profit, which is the difference between its total revenue and its total cost.

Cost of goods sold (COGS) is the carrying value of goods sold during a particular period.

The break-even point (BEP) in economics, business—and specifically cost accounting—is the point at which total cost and total revenue are equal, i.e. "even". In layman's terms, after all costs are paid for there is neither profit nor loss. In economics specifically, the term has a broader definition; even if there is no net loss or gain, and one has "broken even", opportunity costs have been covered and capital has received the risk-adjusted, expected return. The break-even analysis was developed by Karl Bücher and Johann Friedrich Schär.

In economics, the marginal cost is the change in the total cost that arises when the quantity produced is increased, i.e. the cost of producing additional quantity. In some contexts, it refers to an increment of one unit of output, and in others it refers to the rate of change of total cost as output is increased by an infinitesimal amount. As Figure 1 shows, the marginal cost is measured in dollars per unit, whereas total cost is in dollars, and the marginal cost is the slope of the total cost, the rate at which it increases with output. Marginal cost is different from average cost, which is the total cost divided by the number of units produced.

In budgeting, and management accounting in general, a variance is the difference between a budgeted, planned, or standard cost and the actual amount incurred/sold. Variances can be computed for both costs and revenues.

In variance analysis (accounting) direct material total variance is the difference between the actual cost of actual number of units produced and its budgeted cost in terms of material. Direct material total variance can be divided into two components:

In variance analysis (accounting) direct material price variance is the difference between the standard cost and the actual cost for the actual quantity of material purchased. It is one of the two components of direct material total variance.

In economics, a cost curve is a graph of the costs of production as a function of total quantity produced. In a free market economy, productively efficient firms optimize their production process by minimizing cost consistent with each possible level of production, and the result is a cost curve. Profit-maximizing firms use cost curves to decide output quantities. There are various types of cost curves, all related to each other, including total and average cost curves; marginal cost curves, which are equal to the differential of the total cost curves; and variable cost curves. Some are applicable to the short run, others to the long run.

In economics, total cost (TC) is the minimum financial cost of producing some quantity of output. This is the total economic cost of production and is made up of variable cost, which varies according to the quantity of a good produced and includes inputs such as labor and raw materials, plus fixed cost, which is independent of the quantity of a good produced and includes inputs that cannot be varied in the short term such as buildings and machinery, including possibly sunk costs.

Backflush accounting is a subset of management accounting focused on types of "postproduction issuing;" It is a product costing approach, used in a Just-In-Time (JIT) operating environment, in which costing is delayed until goods are finished. Backflush accounting delays the recording of costs until after the events have taken place, then standard costs are used to work backwards to 'flush' out the manufacturing costs. The result is that detailed tracking of costs is eliminated. Journal entries to inventory accounts may be delayed until the time of product completion or even the time of sale, and standard costs are used to assign costs to units when journal entries are made. The backflushing transaction has two steps: one step of the transaction reports the produced part which serves to increase the quantity on-hand of the produced part and a second step which relieves the inventory of all the component parts. Component part numbers and quantities-per are taken from the standard bill of material (BOM). This represents a huge saving over the traditional method of a) issuing component parts one at a time, usually to a discrete work order, b) receiving the finished parts into inventory, and c) returning any unused components, one at a time, back into inventory.

Price variance (Vmp) is a term used in cost accounting which denotes the difference between the expected cost of an item and the actual cost at the time of purchase. The price of an item is often affected by the quantity of items ordered, and this is taken into consideration. A price variance means that actual costs may exceed the budgeted cost, which is generally not desirable. This is important when companies are deciding what quantities of an item to purchase.

A product's average price is the result of dividing the product's total sales revenue by the total units sold. When one product is sold in variants, such as bottle sizes, managers must define "comparable" units. Average prices can be calculated by weighting different unit selling prices by the percentage of unit sales (mix) for each product variant. If we use a standard, rather than an actual mix of sizes and product varieties, the result is price per statistical unit. Statistical units are also called equivalent units.

Cost–volume–profit (CVP), in managerial economics, is a form of cost accounting. It is a simplified model, useful for elementary instruction and for short-run decisions.

In any technical subject, words commonly used in everyday life acquire very specific technical meanings, and confusion can arise when someone is uncertain of the intended meaning of a word. This article explains the differences in meaning between some technical terms used in economics and the corresponding terms in everyday usage.

Direct materials cost the cost of direct materials which can be easily identified with the unit of production. For example, the cost of glass is a direct materials cost in light bulb manufacturing.

The profit model is the linear, deterministic algebraic model used implicitly by most cost accountants. Starting with, profit equals sales minus costs, it provides a structure for modeling cost elements such as materials, losses, multi-products, learning, depreciation etc. It provides a mutable conceptual base for spreadsheet modelers. This enables them to run deterministic simulations or 'what if' modelling to see the impact of price, cost or quantity changes on profitability.