Related Research Articles

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. Electric motors can be powered by direct current (DC) sources, such as from batteries, motor vehicles or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy.

Glass fiber is a material consisting of numerous extremely fine fibers of glass.

Fiberglass, or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet, or woven into a fabric. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinylester—or a thermoplastic.

A commutator is a rotary electrical switch in certain types of electric motors and electrical generators that periodically reverses the current direction between the rotor and the external circuit. It consists of a cylinder composed of multiple metal contact segments on the rotating armature of the machine. Two or more electrical contacts called "brushes" made of a soft conductive material like carbon press against the commutator, making sliding contact with successive segments of the commutator as it rotates. The windings on the armature are connected to the commutator segments.

An alternator is an electrical generator that converts mechanical energy to electrical energy in the form of alternating current. For reasons of cost and simplicity, most alternators use a rotating magnetic field with a stationary armature. Occasionally, a linear alternator or a rotating armature with a stationary magnetic field is used. In principle, any AC electrical generator can be called an alternator, but usually the term refers to small rotating machines driven by automotive and other internal combustion engines.

Fibre-reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use.

A flyback transformer (FBT), also called a line output transformer (LOPT), is a special type of electrical transformer. It was initially designed to generate high voltage sawtooth signals at a relatively high frequency. In modern applications, it is used extensively in switched-mode power supplies for both low (3 V) and high voltage supplies.

A mandrel, mandril, or arbor is:

In electrical engineering, an armature is the component of an electric machine which carries alternating current. The armature windings conduct AC even on DC machines, due to the commutator action or due to electronic commutation, as in brushless DC motors. The armature can be on either the rotor or the stator, depending on the type of electric machine.

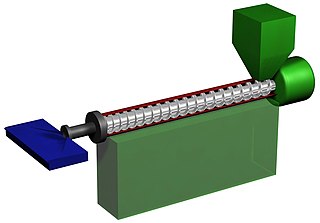

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures. This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle while a delivery eye on a carriage traverses horizontally in line with the axis of the rotating mandrel, laying down fibers in the desired pattern or angle. The most common filaments are glass or carbon and are impregnated in a bath with resin as they are wound onto the mandrel. Once the mandrel is completely covered to the desired thickness, the resin is cured. Depending on the resin system and its cure characteristics, often the rotating mandrel is placed in an oven or placed under radiant heaters until the part is cured. Once the resin has cured, the mandrel is removed or extracted, leaving the hollow final product. For some products such as gas bottles, the 'mandrel' is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored.

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

A dynamo is an electrical generator that creates direct current using a commutator. Dynamos were the first electrical generators capable of delivering power for industry, and the foundation upon which many other later electric-power conversion devices were based, including the electric motor, the alternating-current alternator, and the rotary converter.

A winding machine or winder is a machine for wrapping string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures.

FRP is a modern composite material of construction for chemical plant equipment like tanks and vessels. Chemical equipment that range in size from less than a metre to 20 metres are fabricated using FRP as material of construction.

Helical extrusion technology is applied in the plastic pipe industry. Basically the production process is a direct extrusion. During the pipe production several different materials - depending on the desired final pipe - are mixed in the extrusion unit according to a special formula depending. The production machine is fed with granule material. During the complex extrusion and mixing process a homogeneous profile is helically extruded on a preheated rotating mandrel. In the case that a gravity pipe is being produced the profile is a structured wall and in the case of pressure pipe the profile is a solid wall. The production is a discontinuous procedure.

Carbon fiber reinforced polymer, Carbon fibre reinforced polymer, or carbon fiber reinforced plastic, or carbon fiber reinforced thermoplastic, is an extremely strong and light fiber-reinforced plastic which contains carbon fibers. The spelling 'fibre' is usual outside the USA. CFRPs can be expensive to produce but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructure of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

A continuous filament winding machine is a machine for laying filament windings continuously over a cylindrical steel band. The steel band is carried on a forward moving mandrel which is able to collapse and return to the beginning of the travel. The steel band is released after the mandrel collapses and is continuously fed back to the start of the travel where it is again wound on to the mandrel.

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe.

Flowtite Technology AS is a Norwegian technology company, owned by Amiantit Group. It develops GRP pipe manufacturing technology and designs tailor-made manufacturing equipment under the brand name Flowtite. Its predecessor, Vera Fabrikker, was the first company in the world to utilize a continuous filament winding machine for production of glassfibre-reinforced plastic pipes and to invent the corresponding manufacturing process, commonly known as continuous filament winding process or Drostholm process.