Related Research Articles

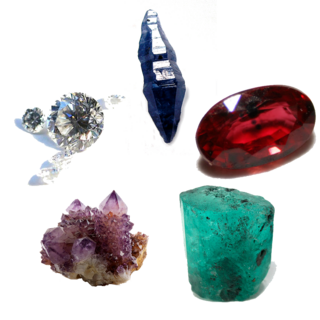

A gemstone is a piece of mineral crystal which, when cut or polished, is used to make jewelry or other adornments. Certain rocks and occasionally organic materials that are not minerals may also be used for jewelry and are therefore often considered to be gemstones as well. Most gemstones are hard, but some softer minerals such as brazilianite may be used in jewelry because of their color or luster or other physical properties that have aesthetic value. However, generally speaking, soft minerals are not typically used as gemstones by virtue of their brittleness and lack of durability.

Topaz is a silicate mineral made of aluminum and fluorine with the chemical formula Al2SiO4(F, OH)2. It is used as a gemstone in jewelry and other adornments. Common topaz in its natural state is colorless, though trace element impurities can make it pale blue or golden brown to yellow-orange. Topaz is often treated with heat or radiation to make it a deep blue, reddish-orange, pale green, pink, or purple.

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

Lapidary is the practice of shaping stone, minerals, or gemstones into decorative items such as cabochons, engraved gems, and faceted designs. A person who practices lapidary is known as a lapidarist. A lapidarist uses the lapidary techniques of cutting, grinding, and polishing. Hardstone carving requires specialized carving techniques.

Cubic zirconia (abbreviated CZ) is the cubic crystalline form of zirconium dioxide (ZrO2). The synthesized material is hard and usually colorless, but may be made in a variety of different colors. It should not be confused with zircon, which is a zirconium silicate (ZrSiO4). It is sometimes erroneously called cubic zirconium.

A cabochon is a gemstone that has been shaped and polished, as opposed to faceted. The resulting form is usually a convex (rounded) obverse with a flat reverse. Cabochon was the default method of preparing gemstones before gemstone cutting developed.

Facets are flat faces on geometric shapes. The organization of naturally occurring facets was key to early developments in crystallography, since they reflect the underlying symmetry of the crystal structure. Gemstones commonly have facets cut into them in order to improve their appearance by allowing them to reflect light.

Sealing wax is a wax material of a seal which, after melting, hardens quickly, forming a bond that is difficult to break without noticeable tampering. Wax is used to verify that something such as a document is unopened, to verify the sender's identity, and as decoration. Sealing wax can also be used to take impressions of other seals. Wax was used to seal letters close and later, from about the 16th century, envelopes. Long before sealing wax was employed, the Romans used bitumen for this purpose.

A diamond simulant, diamond imitation or imitation diamond is an object or material with gemological characteristics similar to those of a diamond. Simulants are distinct from synthetic diamonds, which are actual diamonds exhibiting the same material properties as natural diamonds. Enhanced diamonds are also excluded from this definition. A diamond simulant may be artificial, natural, or in some cases a combination thereof. While their material properties depart markedly from those of diamond, simulants have certain desired characteristics—such as dispersion and hardness—which lend themselves to imitation. Trained gemologists with appropriate equipment are able to distinguish natural and synthetic diamonds from all diamond simulants, primarily by visual inspection.

Ceramic forming techniques are ways of forming ceramics, which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts. Pottery techniques include the potter's wheel, slip casting and many others.

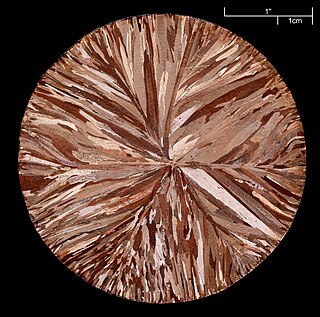

Microcrystalline waxes are a type of wax produced by de-oiling petrolatum, as part of the petroleum refining process. In contrast to the more familiar paraffin wax which contains mostly unbranched alkanes, microcrystalline wax contains a higher percentage of isoparaffinic (branched) hydrocarbons and naphthenic hydrocarbons. It is characterized by the fineness of its crystals in contrast to the larger crystal of paraffin wax. It consists of high molecular weight saturated aliphatic hydrocarbons. It is generally darker, more viscous, denser, tackier and more elastic than paraffin waxes, and has a higher molecular weight and melting point. The elastic and adhesive characteristics of microcrystalline waxes are related to the non-straight chain components which they contain. Typical microcrystalline wax crystal structure is small and thin, making them more flexible than paraffin wax. It is commonly used in cosmetic formulations.

Hot-melt adhesive (HMA), also known as hot glue, is a form of thermoplastic adhesive that is commonly sold as solid cylindrical sticks of various diameters designed to be applied using a hot glue gun. The gun uses a continuous-duty heating element to melt the plastic glue, which the user pushes through the gun either with a mechanical trigger mechanism on the gun, or with direct finger pressure. The glue squeezed out of the heated nozzle is initially hot enough to burn and even blister skin. The glue is sticky when hot, and solidifies in a few seconds to one minute. Hot-melt adhesives can also be applied by dipping or spraying, and are popular with hobbyists and crafters both for affixing and as an inexpensive alternative to resin casting.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel. Aluminium and copper are also continuously cast.

Sealant is a substance used to block the passage of fluids through openings in materials, a type of mechanical seal. In building construction sealant is sometimes synonymous with caulk and also serve the purposes of blocking dust, sound and heat transmission. Sealants may be weak or strong, flexible or rigid, permanent or temporary. Sealants are not adhesives but some have adhesive qualities and are called adhesive-sealants or structural sealants.

Stonesetting is the art of securely setting or attaching gemstones into jewelry.

A faceting machine is broadly defined as any device that allows the user to place and polish facets onto a mineral specimen. Machines can range in sophistication from primitive jamb-peg machines to highly refined, and highly expensive, commercially available machines. A major division among machines is found between those that facet diamonds and those that do not. Specialized equipment is required for diamond faceting, and faceting as an occupation rarely bridges the gap between diamond and non-diamond workmanship. A second division can be made between industrial faceting and custom/hobby faceting. The vast majority of jewelry-store gemstones are faceted either abroad in factories or entirely by machines. Custom jewelry is still commonly made of custom metalwork and mass-produced gemstones, but unusual cuts or particularly valuable gemstone material will likely be faceted on a personal faceting machine.

A bezel is a wider and usually thicker section of the hoop of a ring, which may contain a gem or a flat surface. Rings are normally worn to display bezels on the upper or outer side of the finger. In gem-cutting the term bezel is used for those sloping facets of a cut stone that surround the flat table face, which is the large, horizontal facet on the top.

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC.

Chaser's pitch is a thermal adhesive used by goldsmiths, silversmiths, coppersmiths, and other metal cold-working artisans to hold a metal plate for repoussage and "chasing" (embossing) while it is being hammered out.

References

- 1 2 3 4 5 6 H. Dake (2013): The Art of Gem Cutting - Including Cabochons, Faceting, Spheres, Tumbling and Special Techniques . Read Books; 98 pages. ISBN 9781447484806

- ↑ John Sinkankas (2014): Gem Cutting: A Lapidary's Manual , 2nd Edition. Echo Point; 322 pages. ISBN 9781626540248

- ↑ Bill James (1965): Collecting Australian Gemstones. Murray; 191 pages. ISBN 978-0855660154

- 1 2 (2019): "Adhesives"; featuring brown, green, and black dop wax sticks. Graves Company online catalog page. Accessed on 2019-04-19.

- 1 2 3 (2019): "Diamond Setters Cement"; reddish brown, as a 1/4 pound square slab. Romanoff company online catalog page. Accessed on 2019-04-19.

- ↑ Mohsen Manutchehr-Danai (2013): Dictionary of Gems and Gemology. Springer; 565 pages. ISBN 9783662042885

- ↑ J. Sean Keane (2019): "Choosing The Best Faceting Wax For Your Task". Online advice page, International Gem Society. Accessed on 2019-04-19.