Spinning is the twisting together of drawn-out strands of fibers to form yarn, and is a major part of the textile industry. The yarn is then used to create textiles, which are then used to make clothing and many other products. There are several industrial processes available to spin yarn, as well as hand-spinning techniques where the fiber is drawn out, twisted, and wound onto a bobbin.

In computer science, a thread of execution is the smallest sequence of programmed instructions that can be managed independently by a scheduler, which is typically a part of the operating system. The implementation of threads and processes differs between operating systems, but in most cases a thread is a component of a process. Multiple threads can exist within one process, executing concurrently and sharing resources such as memory, while different processes do not share these resources. In particular, the threads of a process share its executable code and the values of its dynamically allocated variables and non-thread-local global variables at any given time.

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, or ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework.

A spinning wheel is a device for spinning thread or yarn from natural or synthetic fibres. Spinning wheels were first used in India, between 500 and 1000 A.D. Spinning machinery, such as the spinning jenny and spinning frame, displaced the spinning wheel during the Industrial Revolution.

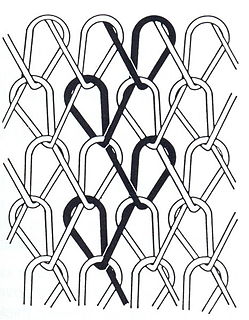

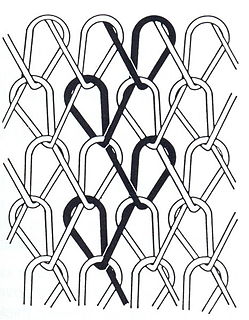

A shackle, also known as a gyve, is a U-shaped piece of metal secured with a clevis pin or bolt across the opening, or a hinged metal loop secured with a quick-release locking pin mechanism. The term also applies to handcuffs and other similarly conceived restraint devices that function in a similar manner. Shackles are the primary connecting link in all manner of rigging systems, from boats and ships to industrial crane rigging, as they allow different rigging subsets to be connected or disconnected quickly. A shackle is also the similarly shaped piece of metal used with a locking mechanism in padlocks.

Woolen or woollen is a type of yarn made from carded wool. Woolen yarn is soft, light, stretchy, and full of air. It is thus a good insulator, and makes a good knitting yarn. Woolen yarn is in contrast to worsted yarn, in which the fibers are combed to lie parallel rather than carded, producing a hard, strong yarn.

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

Textile manufacturing is a major industry. It is based on the conversion of fiber into yarn, yarn into fabric. These are then dyed or printed, fabricated into clothes. Different types of fibers are used to produce yarn. Cotton remains the most important natural fiber, so is treated in depth. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide ranges of products. There remains a large industry that uses hand techniques to achieve the same results.

Brazilian embroidery is a type of surface embroidery that uses rayon thread instead of cotton or wool. It is called "Brazilian" embroidery because the use of high-sheen rayon thread in embroidery was first popularized in Brazil, where rayon was widely manufactured. Brazilian embroidery patterns usually include flowers formed using both knotted and cast on stitches. Rayon thread, which is smooth and shiny, makes it easier to pull the needle through the wrapped stitches, such as bullion stitches. Milliners needles, which have a straight shaft and an eye area no wider than the shaft, are usually used for the wrapped stitches that are frequently used in Brazilian embroidery.

The eye splice is a method of creating a permanent loop in the end of a rope by means of rope splicing.

Warp knitting is a family of knitting methods in which the yarn zigzags along the length of the fabric; i.e., following adjacent columns, or wales, of knitting, rather than a single row, or course. For comparison, knitting across the width of the fabric is called weft knitting.

In computer science, a fiber is a particularly lightweight thread of execution.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

A bowstring joins the two ends of the bow stave and launches the arrow. Desirable properties include light weight, strength, resistance to abrasion, and resistance to water. Mass has most effect at the center of the string; one gram (0.035 oz) of extra mass in the middle of the string slows the arrow about as much as 3.5 grams (0.12 oz) at the ends.

Heat setting is a term used in the textile industry to describe a thermal process usually taking place in either a steam atmosphere or a dry heat environment. The effect of the process gives fibers, yarns or fabric dimensional stability and, very often, other desirable attributes like higher volume, wrinkle resistance or temperature resistance. Very often, heat setting is also used to improve attributes for subsequent processes.

Novelty yarns include a wide variety of yarns made with unusual features, structure or fiber composition such as slubs, inclusions, metallic or synthetic fibers, laddering and varying thickness introduced during production. Some linens, wools to be woven into tweed, and the uneven filaments of some types of silk are allowed to retain their normal irregularities, producing the characteristic uneven surface of the finished fabric. Man-made fibres, which can be modified during production, are especially adaptable for special effects such as crimping and texturizing.

Short draw is the spinning technique used to create worsted yarns. It is spun from combed roving, sliver or wool top – anything with the fibers all lined up parallel to the yarn. It is generally spun from long stapled fibers. Short draw spun yarns are smooth, strong, sturdy yarns, and dense. Short draw spun yarns also tend to not be very elastic. These characteristics make them good for use in weaving.

Long draw is the spinning technique used to create woolen yarns. It is spun from carded rolags. It is generally spun from shorter stapled fibers. Long draw spun yarns are light, lofty, stretchy, soft, and full of air, thus they are good insulators, and make good knitting yarns.

String is a long flexible structure made from fibers twisted together into a single strand, or from multiple such strands which are in turn twisted together. String is used to tie, bind, or hang other objects. It is also used as a material to make things, such as textiles, and in arts and crafts. String is a simple tool, and its use by humans is known to have been developed tens of thousands of years ago. In Mesoamerica, for example, string was invented some 20,000 to 30,000 years ago, and was made by twisting plant fibers together. String may also be a component in other tools, and in devices as diverse as weapons, musical instruments, and toys.