In computing, a printer is a peripheral machine which makes a durable representation of graphics or text, usually on paper. While most output is human-readable, bar code printers are an example of an expanded use for printers. Different types of printers include 3D printers, inkjet printers, laser printers, and thermal printers.

Laser printing is an electrostatic digital printing process. It produces high-quality text and graphics by repeatedly passing a laser beam back and forth over a negatively charged cylinder called a "drum" to define a differentially charged image. The drum then selectively collects electrically charged powdered ink (toner), and transfers the image to paper, which is then heated to permanently fuse the text, imagery, or both, to the paper. As with digital photocopiers, laser printers employ a xerographic printing process. Laser printing differs from traditional xerography as implemented in analog photocopiers in that in the latter, the image is formed by reflecting light off an existing document onto the exposed drum.

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensive consumer models to expensive professional machines. By 2019, laser printers outsold inkjet printers by nearly a 2:1 ratio, 9.6% vs 5.1% of all computer peripherals.

Dye-sublimation printing is a term that covers several distinct digital computer printing techniques that involve using heat to transfer dye onto a substrate.

Dots per inch is a measure of spatial printing, video or image scanner dot density, in particular the number of individual dots that can be placed in a line within the span of 1 inch (2.54 cm). Similarly, dots per centimetre refers to the number of individual dots that can be placed within a line of 1 centimetre (0.394 in).

Digital printing is a method of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers.

A film recorder is a graphical output device for transferring images to photographic film from a digital source. In a typical film recorder, an image is passed from a host computer to a mechanism to expose film through a variety of methods, historically by direct photography of a high-resolution cathode ray tube (CRT) display. The exposed film can then be developed using conventional developing techniques, and displayed with a slide or motion picture projector. The use of film recorders predates the current use of digital projectors, which eliminate the time and cost involved in the intermediate step of transferring computer images to film stock, instead directly displaying the image signal from a computer. Motion picture film scanners are the opposite of film recorders, copying content from film stock to a computer system. Film recorders can be thought of as modern versions of Kinescopes.

The gelatin silver process is the most commonly used chemical process in black-and-white photography, and is the fundamental chemical process for modern analog color photography. As such, films and printing papers available for analog photography rarely rely on any other chemical process to record an image. A suspension of silver salts in gelatin is coated onto a support such as glass, flexible plastic or film, baryta paper, or resin-coated paper. These light-sensitive materials are stable under normal keeping conditions and are able to be exposed and processed even many years after their manufacture. The "dry plate" gelatin process was an improvement on the collodion wet-plate process dominant from the 1850s–1880s, which had to be exposed and developed immediately after coating.

Pixels per inch (ppi) and pixels per centimetre are measurements of the pixel density of an electronic image device, such as a computer monitor or television display, or image digitizing device such as a camera or image scanner. Horizontal and vertical density are usually the same, as most devices have square pixels, but differ on devices that have non-square pixels. Pixel density is not the same as resolution — where the former describes the amount of detail on a physical surface or device, the latter describes the amount of pixel information regardless of its scale. Considered in another way, a pixel has no inherent size or unit, but when it is printed, displayed, or scanned, then the pixel has both a physical size (dimension) and a pixel density (ppi).

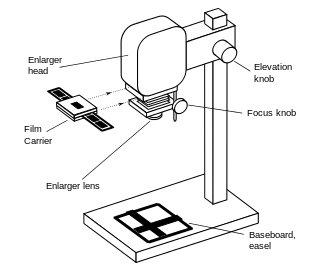

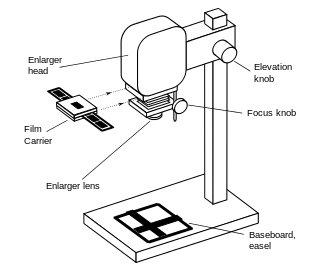

An enlarger is a specialized transparency projector used to produce photographic prints from film or glass negatives, or from transparencies.

A contact print is a photographic image produced from film; sometimes from a film negative, and sometimes from a film positive or paper negative. In a darkroom an exposed and developed piece of film or photographic paper is placed emulsion side down, in contact with a piece of photographic paper, light is briefly shone through the negative or paper and then the paper is developed to reveal the final print.

Photographic printing is the process of producing a final image on paper for viewing, using chemically sensitized paper. The paper is exposed to a photographic negative, a positive transparency , or a digital image file projected using an enlarger or digital exposure unit such as a LightJet or Minilab printer. Alternatively, the negative or transparency may be placed atop the paper and directly exposed, creating a contact print. Digital photographs are commonly printed on plain paper, for example by a color printer, but this is not considered "photographic printing".

A minilab is a small photographic developing and printing system or machine, as opposed to large centralized photo developing labs. Many retail stores use film or digital minilabs to provide on-site photo finishing services.

An Iris printer is a large-format color inkjet printer designed for prepress proofing. It was introduced in 1985 by Iris Graphics, originally of Stoneham, Massachusetts, and is currently manufactured by the Graphic Communications Group of Eastman Kodak. It is also used in the fine art reproduction market as a final output digital printing press, as in Giclée.

Wide format printers are generally accepted to be any computer-controlled printing machines (printers) that support a maximum print roll width of between 18 and 100 inches. Printers with capacities over 100 in wide are considered super-wide or grand format. Wide-format printers are used to print banners, posters, trade show graphics, wallpaper, murals, backlit film (duratrans), vehicle image wraps, electronic circuit schematics, architectural drawings, construction plans, backdrops for theatrical and media sets, and any other large format artwork or signage. Wide-format printers usually employ some variant of inkjet or toner-based technology to produce the printed image; and are more economical than other print methods such as screen printing for most short-run print projects, depending on print size, run length, and the type of substrate or print medium. Wide-format printers are usually designed for printing onto a roll of print media that feeds incrementally during the print process, rather than onto individual sheets.

LightJet is a brand of hardware used for photographic printing of digital images to photographic paper and film. LightJet printers are no longer manufactured but are however remanufactured and resold; and their lasers are still manufactured.

A chromogenic print, also known as a C-print or C-type print, a silver halide print, or a dye coupler print, is a photographic print made from a color negative, transparency or digital image, and developed using a chromogenic process. They are composed of three layers of gelatin, each containing an emulsion of silver halide, which is used as a light-sensitive material, and a different dye coupler of subtractive color which together, when developed, form a full-color image.

Flatbed digital printers, also known as flatbed printers or flatbed UV printers, are printers characterized by a flat surface upon which a material is placed to be printed on. Flatbed printers are capable of printing on a wide variety of materials such as photographic paper, film, cloth, plastic, pvc, acrylic, glass, ceramic, metal, wood, leather, etc.). Flatbed digital printers usually use UV curable inks made of acrylic monomers that are then exposed to strong UV-light to cure, or polymerize them. This process allows for printing on a wide variety of surfaces such as wood or canvas, carpet, tile, and even glass. The adjustable printing bed makes it possible to print on surfaces ranging in thickness from a sheet of paper often up to as much as several inches. Typically used for commercial applications, flatbed printing is often a substitute for screen-printing. Since no printing plates or silkscreens must be produced, digital printing technology allows shorter runs of signs to be produced economically. Many of the high-end flatbed printers allow for roll-feed, allowing for unattended printing.

The digital negative is the collective name for methods used by photographers to create negatives on transparency film for the contact printing of alternative photographic techniques. The negatives can also be enlarged using traditional gelatin silver processes, though this is usually reserved for negatives of 4x5" or larger due to quality limitations imposed by printer technology. This set of techniques is separate from the Digital negative (DNG) file format, although this format may be used to create digital negative transparencies.

Art photography print types refers to the process and paper of how the photograph is printed and developed.