Related Research Articles

Mining is the extraction of valuable geological materials and minerals from the Earth and other astronomical objects. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. The ore must be a rock or mineral that contains valuable constituent, can be extracted or mined and sold for profit. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water.

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials science, covering all aspects of the types of ore, washing, concentration, separation, chemical processes and extraction of pure metal and their alloying to suit various applications, sometimes for direct use as a finished product, but more often in a form that requires further working to achieve the given properties to suit the applications.

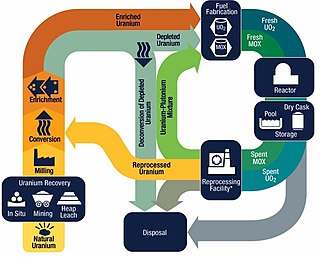

The nuclear fuel cycle, also called nuclear fuel chain, is the progression of nuclear fuel through a series of differing stages. It consists of steps in the front end, which are the preparation of the fuel, steps in the service period in which the fuel is used during reactor operation, and steps in the back end, which are necessary to safely manage, contain, and either reprocess or dispose of spent nuclear fuel. If spent fuel is not reprocessed, the fuel cycle is referred to as an open fuel cycle ; if the spent fuel is reprocessed, it is referred to as a closed fuel cycle.

Mining in the engineering discipline is the extraction of minerals from underneath, open pit, above, or on the ground. Mining engineering is associated with many other disciplines, such as mineral processing, exploration, excavation, geology, and metallurgy, geotechnical engineering and surveying. A mining engineer may manage any phase of mining operations, from exploration and discovery of the mineral resources, through feasibility study, mine design, development of plans, production and operations to mine closure.

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. Depending on the processes used in each instance, it is often also known as ore dressing or ore milling.

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and re-separate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ore, whereas in situ mining lacks these liners and pulls pregnant solution up to obtain the minerals. Heap leaching is widely used in modern large-scale mining operations as it produces the desired concentrates at a lower cost compared to conventional processing methods such as flotation, agitation, and vat leaching.

Uranium mining is the process of extraction of uranium ore from the ground. Over 50 thousand tons of uranium were produced in 2019. Kazakhstan, Canada, and Australia were the top three uranium producers, respectively, and together account for 68% of world production. Other countries producing more than 1,000 tons per year included Namibia, Niger, Russia, Uzbekistan, the United States, and China. Nearly all of the world's mined uranium is used to power nuclear power plants. Historically uranium was also used in applications such as uranium glass or ferrouranium but those applications have declined due to the radioactivity of uranium and are nowadays mostly supplied with a plentiful cheap supply of depleted uranium which is also used in uranium ammunition. In addition to being cheaper, depleted uranium is also less radioactive due to a lower content of short-lived 234

U and 235

U than natural uranium.

Nuclear power construction costs have varied significantly across the world and in time. Large and rapid increases in cost occurred during the 1970s, especially in the United States. Recent cost trends in countries such as Japan and Korea have been very different, including periods of stability and decline in costs.

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has pioneered several significant mining industry innovations, including the Isa Process copper refining technology, the Isasmelt smelting technology, and the IsaMill fine grinding technology, and it also commercialized the Jameson Cell column flotation technology.

In-situ leaching (ISL), also called in-situ recovery (ISR) or solution mining, is a mining process used to recover minerals such as copper and uranium through boreholes drilled into a deposit, in situ. In situ leach works by artificially dissolving minerals occurring naturally in a solid state. For recovery of material occurring naturally in solution, see: Brine mining.

In metallurgical processes tank leaching is a hydrometallurgical method of extracting valuable material from ore.

Geometallurgy relates to the practice of combining geology or geostatistics with metallurgy, or, more specifically, extractive metallurgy, to create a spatially or geologically based predictive model for mineral processing plants. It is used in the hard rock mining industry for risk management and mitigation during mineral processing plant design. It is also used, to a lesser extent, for production planning in more variable ore deposits.

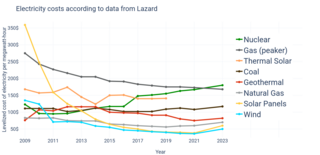

The levelized cost of electricity (LCOE) is a measure of the average net present cost of electricity generation for a generator over its lifetime. It is used for investment planning and to compare different methods of electricity generation on a consistent basis.

Natural resource economics deals with the supply, demand, and allocation of the Earth's natural resources. One main objective of natural resource economics is to better understand the role of natural resources in the economy in order to develop more sustainable methods of managing those resources to ensure their availability for future generations. Resource economists study interactions between economic and natural systems, with the goal of developing a sustainable and efficient economy.

Sensor-based sorting, is an umbrella term for all applications in which particles are detected using a sensor technique and rejected by an amplified mechanical, hydraulic or pneumatic process.

Montana silver mining was a major industry in the 1800s following discovery of numerous silver deposits. Between 1883 and 1891 Montana was second every year to Colorado in silver production, except for 1887 when Montana was number one, producing approximately $15.5 million worth of silver. Major mining districts in Montana included Butte, which was home to many important mines such as the Lexington, Alice, and Moulton mines, and Philipsburg, which housed the Granite Mountain and Bimetallic mines. Other influential, but significantly smaller mines, operated at Helena and the Castle Mountains. The rapid raise and fall of these mines were due to largely geological and economic factors that created favorable conditions for a silver mining boom and subsequent bust. Montana continued to produce considerable silver through most of the 1900s, as a byproduct of copper production at Butte.

Mineral resource estimation is used to determine and define the ore tonnage and grade of a geological deposit, from the developed block model. There are different estimation methods used for different scenarios dependent upon the ore boundaries, geological deposit geometry, grade variability and the amount of time and money available. A typical resource estimation involves the construction of a geological and resource model with data from various sources. Depending on the nature of the information and whether the data is hard copy or computerized, the principal steps of computer resource estimation are:

- Creation, standardization and validation of the database.

- Section plotting and interactive geological modeling.

- Geostatistical analysis.

- Block modeling and block estimation.

Regolith-hosted rare earth element deposits are rare-earth element (REE) ores in decomposed rocks that are formed by intense weathering of REE-rich parental rocks in subtropical areas. In these areas, rocks are intensely broken and decomposed. Then, REEs infiltrate downward with rain water and they are concentrated along a deeper weathered layer beneath the ground surface.

Oil and gas reserves denote discovered quantities of crude oil and natural gas that can be profitably produced/recovered from an approved development. Oil and gas reserves tied to approved operational plans filed on the day of reserves reporting are also sensitive to fluctuating global market pricing. The remaining resource estimates are likely sub-commercial and may still be under appraisal with the potential to be technically recoverable once commercially established. Natural gas is frequently associated with oil directly and gas reserves are commonly quoted in barrels of oil equivalent (BoE). Consequently, both oil and gas reserves, as well as resource estimates, follow the same reporting guidelines, and are referred to collectively hereinafter as oil & gas.

References

- ↑ K. Loska, D. Wiechula, J. Pelczar, Application of Enrichment Factor to Assessment of Zinc Enrichment/Depletion in Farming Soils, Communications in Soil Science and Plant Analysis, Volume 36, Issue 9 & 10 May 2005, pages 1117 - 1128