Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics.

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

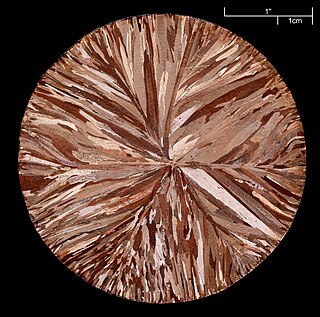

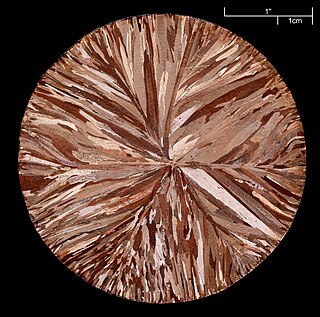

Wrought iron is an iron alloy with a very low carbon content in contrast to that of cast iron. It is a semi-fused mass of iron with fibrous slag inclusions, which gives it a "grain" resembling wood that is visible when it is etched, rusted, or bent to the point of failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

An ingot is a piece of relatively pure material, usually metal, that is cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedure of shaping, such as cold/hot working, cutting, or milling to produce a useful final product. Non-metallic and semiconductor materials prepared in bulk form may also be referred to as ingots, particularly when cast by mold based methods. Precious metal ingots can be used as currency, or as a currency reserve, as with gold bars.

In metallurgy, a flux is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining.

Forge welding (FOW), also called fire welding, is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together with presses or other means, creating enough pressure to cause plastic deformation at the weld surfaces. The process is one of the simplest methods of joining metals and has been used since ancient times, being a staple of traditional blacksmithing. Forge welding is versatile, being able to join a host of similar and dissimilar metals. With the invention of electrical welding and gas welding methods during the Industrial Revolution, manual forge-welding has been largely replaced, although automated forge-welding is a common manufacturing process.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process.

Ceramic forming techniques are ways of forming ceramics, which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts. Pottery techniques include the potter's wheel, slip casting and many others.

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel. Aluminium and copper are also continuously cast.

Thermal spraying techniques are coating processes in which melted materials are sprayed onto a surface. The "feedstock" is heated by electrical or chemical means.

In casting, a pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process.

Glass-to-metal seals are a very important element of the construction of vacuum tubes, electric discharge tubes, incandescent light bulbs, glass encapsulated semiconductor diodes, reed switches, pressure tight glass windows in metal cases, and metal or ceramic packages of electronic components.

A casting defect is an undesired irregularity in a metal casting process. Some defects can be tolerated while others can be repaired, otherwise they must be eliminated. They are broken down into five main categories: gas porosity, shrinkage defects, mould material defects, pouring metal defects, and metallurgical defects.

An inclusion is a solid particle in liquid aluminium alloy. It is usually non-metallic and can be of different nature depending on its source.

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together.

Ultra-high-purity steam, also called the clean steam, UHP steam or high purity water vapor, is used in a variety of industrial manufacturing processes that require oxidation or annealing. These processes include the growth of oxide layers on silicon wafers for the semiconductor industry, originally described by the Deal-Grove model, and for the formation of passivation layers used to improve the light capture ability of crystalline photovoltaic cells. Several methods and technologies can be employed to generate ultra high purity steam, including pyrolysis, bubbling, direct liquid injection and purified steam generation. The level of purity, or the relative lack of contamination, affects the quality of the oxide layer or annealed surface. The method of delivery affects growth rate, uniformity and electrical performance. Oxidation and annealing are common steps in the manufacture of such devices as microelectronics and solar cells.

The strength of metal oxide adhesion effectively determines the wetting of the metal-oxide interface. The strength of this adhesion is important, for instance, in production of light bulbs and fiber-matrix composites that depend on the optimization of wetting to create metal-ceramic interfaces. The strength of adhesion also determines the extent of dispersion on catalytically active metal. Metal oxide adhesion is important for applications such as complementary metal oxide semiconductor devices. These devices make possible the high packing densities of modern integrated circuits.