Sources

![]() This article incorporates text from a free content work.Licensed under CC BY-SA 3.0.Text taken from Evaporative cooling chamber . Energypedia.

This article incorporates text from a free content work.Licensed under CC BY-SA 3.0.Text taken from Evaporative cooling chamber . Energypedia.

Evaporative cooling chambers (ECCs), also known as "zero energy cool chambers" (ZECCs), are a type of evaporative cooler, which are simple and inexpensive ways to keep vegetables fresh without the use of electricity. Evaporation of water from a surface removes heat, creating a cooling effect, which can improve vegetable storage shelf life.

ECCs are relatively large compared to the more common household clay pot cooler, and are therefore most suitable for farmers with large production quantities, farming groups, or farming cooperatives.

The brick ECC was originally developed in India by Susanta K. Roy and D.S. Khuridiya in the early 1980s to address fruit and vegetable post-harvest losses, especially in rural areas where electricity is non-existent. [1] [2] Roy and Khuridiya’s ECC design is composed of a double brick wall structure, supported by a base layer of brick, and covered with a straw mat.

ECCs provide the most benefits when they are used in low humidity climates (less than 40% relative humidity), the temperature is hot (maximum daily temperature greater than 25 °C), water is available to add to the device between one and three times per day. The device should be in a shady and well-ventilated area.

Additionally, storage conditions must meet users’ needs for scale of storage needed and optimal conditions for different vegetables throughout the year. The cost of the ECC must be affordable and justified by the benefits be realized due to its improved storage. [3] [4]

The size of an ECC can be chosen to meet a range of user storage needs; however, the cost can vary significantly based on the desired size and local cost of materials. Because ECCs can be constructed over a range of sizes, it is important to select an appropriate size according to the need to avoid over-building and spending more money than is needed.

Evaporative cooling chambers (ECCs) can be made from locally available materials, including bricks, sand, wood, dry grass, gunny/burlap sacks, and twine. The space in between the two brick walls is filled with sand, which retains the water that is added. If the evaporative cooling chamber is not built in an area that is well shaded, a shed must be constructed to provide shade. Inside the ECC, food is placed in unsealed plastic containers, which keep the vegetables off the ECC’s floor and allows them to breathe and be exposed to the cool, humid air inside the device. [5] [6] [7]

It is important that ECCs are correctly used to ensure maximum cooling performance benefit for the user. Improper use decreases the potential benefits and results in a lower cost-benefit ratio. The vegetables that need storage should be carefully considered, since not all produce can be stored together because some release ethylene, which can accelerate ripening or reduce post-harvest quality.

Before starting to build an ECC, a location should be chosen that is close to water, exposed to wind/breeze, and if possible, where there is shade to avoid the need of a cover. ECCs should be reinstalled every 3 years with new bricks. The cover of the ECC should be opened as infrequently as possible to keep the cool air in. The sand between the bricks must be kept wet; installing an irrigation system can make this process simpler. Additionally, water should be sprinkled on the cover 1-3 times per day.

![]() This article incorporates text from a free content work.Licensed under CC BY-SA 3.0.Text taken from Evaporative cooling chamber . Energypedia.

This article incorporates text from a free content work.Licensed under CC BY-SA 3.0.Text taken from Evaporative cooling chamber . Energypedia.

Solar energy is the radiant energy from the Sun's light and heat, which can be harnessed using a range of technologies such as solar electricity, solar thermal energy and solar architecture. It is an essential source of renewable energy, and its technologies are broadly characterized as either passive solar or active solar depending on how they capture and distribute solar energy or convert it into solar power. Active solar techniques include the use of photovoltaic systems, concentrated solar power, and solar water heating to harness the energy. Passive solar techniques include designing a building for better daylighting, selecting materials with favorable thermal mass or light-dispersing properties, and organize spaces that naturally circulate air.

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

Liquid hydrogen (H2(l)) is the liquid state of the element hydrogen. Hydrogen is found naturally in the molecular H2 form.

In passive solar building design, windows, walls, and floors are made to collect, store, reflect, and distribute solar energy, in the form of heat in the winter and reject solar heat in the summer. This is called passive solar design because, unlike active solar heating systems, it does not involve the use of mechanical and electrical devices.

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

A dehumidifier is an air conditioning device which reduces and maintains the level of humidity in the air. This is done usually for health or thermal comfort reasons or to eliminate musty odor and to prevent the growth of mildew by extracting water from the air. It can be used for household, commercial, or industrial applications. Large dehumidifiers are used in commercial buildings such as indoor ice rinks and swimming pools, as well as manufacturing plants or storage warehouses. Typical air conditioning systems combine dehumidification with cooling, by operating cooling coils below the dewpoint and draining away the water that condenses.

A heat pipe is a heat-transfer device that employs phase transition to transfer heat between two solid interfaces.

An evaporative cooler is a device that cools air through the evaporation of water. Evaporative cooling differs from other air conditioning systems, which use vapor-compression or absorption refrigeration cycles. Evaporative cooling exploits the fact that water will absorb a relatively large amount of heat in order to evaporate. The temperature of dry air can be dropped significantly through the phase transition of liquid water to water vapor (evaporation). This can cool air using much less energy than refrigeration. In extremely dry climates, evaporative cooling of air has the added benefit of conditioning the air with more moisture for the comfort of building occupants.

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream. As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function.

A yakhchāl is an ancient type of ice house, which also made ice. They are primarily found in the Dasht-e Lut and Dasht-e-Kavir deserts, whose climates range from cold (BWk) to hot (BWh) desert regions.

An icemaker, ice generator, or ice machine may refer to either a consumer device for making ice, found inside a home freezer; a stand-alone appliance for making ice, or an industrial machine for making ice on a large scale. The term "ice machine" usually refers to the stand-alone appliance.

A pot-in-pot refrigerator, clay pot cooler or zeer is an evaporative cooling refrigeration device which does not use electricity. It uses a porous outer clay pot containing an inner pot within which the food is placed. The evaporation of the outer liquid draws heat from the inner pot. The device can cool any substance, and requires only a flow of relatively dry air and a source of water.

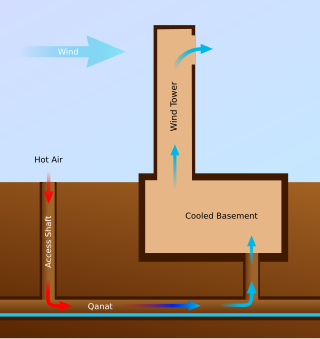

A ground-coupled heat exchanger is an underground heat exchanger that can capture heat from and/or dissipate heat to the ground. They use the Earth's near constant subterranean temperature to warm or cool air or other fluids for residential, agricultural or industrial uses. If building air is blown through the heat exchanger for heat recovery ventilation, they are called earth tubes.

A ground source heat pump is a heating/cooling system for buildings that use a type of heat pump to transfer heat to or from the ground, taking advantage of the relative constancy of temperatures of the earth through the seasons. Ground-source heat pumps (GSHPs) – or geothermal heat pumps (GHP), as they are commonly termed in North America – are among the most energy-efficient technologies for providing HVAC and water heating, using far less energy than can be achieved by burning a fuel in a boiler/furnace or by use of resistive electric heaters.

An evaporator is a type of heat exchanger device that facilitates evaporation by utilizing conductive and convective heat transfer, which provides the necessary thermal energy for phase transition from liquid to vapour. Within evaporators, a circulating liquid is exposed to an atmospheric or reduced pressure environment causing it to boil at a lower temperature compared to normal atmospheric boiling.

Solar energy is clean and renewable.

Pumpable icetechnology (PIT) uses thin liquids, with the cooling capacity of ice. Pumpable ice is typically a slurry of ice crystals or particles ranging from 5 micrometers to 1 cm in diameter and transported in brine, seawater, food liquid, or gas bubbles of air, ozone, or carbon dioxide.

Zero-carbon housing is housing that does not emit greenhouse gasses (GHGs) into the atmosphere, either directly, or indirectly due to consumption electricity produced using fossil fuels. Most commonly zero-carbon housing is taken to mean zero emissions of carbon dioxide, which is the main climate pollutant from homes, although fugitive methane may also be emitted from natural gas pipes and appliances.

Turbine inlet air cooling is a group of technologies and techniques consisting of cooling down the intake air of the gas turbine. The direct consequence of cooling the turbine inlet air is power output augmentation. It may also improve the energy efficiency of the system. This technology is widely used in hot climates with high ambient temperatures that usually coincides with on-peak demand period.

Vacuum cooling is a rapid cooling technique for any porous product that has free water and uses the principle of evaporative cooling. Vacuum cooling is generally used for cooling food products that have a high water content and large porosities, due to its efficacy in losing water from both within and outside the products. This is the most widely used technique for rapid cooling of food products which has been proven to be one of the most efficient and economical methods of cooling and storage of vegetables, fruits, flowers, and more.