James Hall Nasmyth was a Scottish engineer, philosopher, artist and inventor famous for his development of the steam hammer. He was the co-founder of Nasmyth, Gaskell and Company manufacturers of machine tools. He retired at the age of 48, and moved to Penshurst, Kent where he developed his hobbies of astronomy and photography.

The Kelham Island Museum is an industrial museum on Alma Street, alongside the River Don, in the centre of Sheffield, England. It was opened in 1982.

Abinger Hammer is a village in the Vale of Holmesdale, located on the A25 in Surrey, England. The village is located within the Surrey Hills AONB, approximately midway between the market towns of Dorking and Guildford. The village is named after its water-powered iron forge.

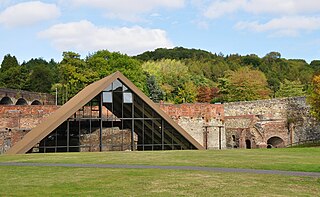

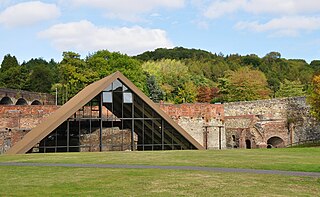

Coalbrookdale is a village in the Ironbridge Gorge and the Telford and Wrekin borough of Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

The River Eden is a tributary of the River Medway in south east England. It rises at the foot of the North Downs escarpment near Titsey in Surrey and runs initially southwards through Oxted before turning eastwards to enter Kent. After flowing through Edenbridge and passing Hever Castle, the Eden meets the Medway at Penshurst.

Abbeydale Industrial Hamlet is an industrial museum in the south of the City of Sheffield, England. The museum forms part of a former steel-working site on the River Sheaf, with a history going back to at least the 13th century. It consists of a number of dwellings and workshops that were formerly the Abbeydale Works—a scythe-making plant that was in operation until the 1930s—and is a remarkably complete example of a 19th-century works. The works are atypical in that much of the production process was completed on the same site. A more typical example of water-powered works in the area can be found at Shepherd Wheel.

Sticklepath is a village and civil parish on Dartmoor, in the county of Devon, England. It gives its name to one of the most important geological faults in south-west England, thought to have originated during the Tertiary period and known variously as the Sticklepath fault, Sticklepath fault zone, Lustleigh-Sticklepath fault or Sticklepath-Lustleigh fault.

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, decorticating and polishing of grain in agriculture. In mining, trip hammers were used for crushing metal ores into small pieces, although a stamp mill was more usual for this. In finery forges they were used for drawing out blooms made from wrought iron into more workable bar iron. They were also used for fabricating various articles of wrought iron, latten, steel and other metals.

Haigh is a village and civil parish in the Metropolitan Borough of Wigan, Greater Manchester, England. Historically part of Lancashire, it is located next to the village of Aspull. The western boundary is the River Douglas, which separates the township from Wigan. To the north, a small brook running into the Douglas divides it from Blackrod. At the 2001 census it had a population of 594.

Halton-with-Aughton is a civil parish and electoral ward located 3 miles (5 km) east of Lancaster, England, on the north bank of the River Lune. The main settlement is the village of Halton, or Halton-on-Lune, in the west, and the parish stretches to the hamlet of Aughton in the east. It lies in the City of Lancaster district of Lancashire, and has a population of 2,227, down from 2,360 in 2001.

Saugus Iron Works National Historic Site is a National Historic Site about 10 miles northeast of Downtown Boston in Saugus, Massachusetts. It is the site of the first integrated ironworks in North America, founded by John Winthrop the Younger and in operation between 1646 and approximately 1670. It includes the reconstructed blast furnace, forge, rolling mill, shear, slitter and a quarter-ton trip hammer.

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery throughout a workshop or an industrial complex. The central power source could be a water wheel, turbine, windmill, animal power or a steam engine. Power was distributed from the shaft to the machinery by a system of belts, pulleys and gears known as millwork.

Blakenhall is a small village and former civil parish, now in the parish of Doddington and District, in the unitary authority area of Cheshire East and the ceremonial county of Cheshire, England, about 7 miles (11 km) south-east of Nantwich. It lies on the county boundary with Staffordshire. The parish has an area of 654 hectares and also includes the small settlements of The Den and Gonsley Green, with a total population of 125 in 2001. Nearby villages include Wybunbury in Cheshire and Betley and Wrinehill in Staffordshire. Blakenhall was first recorded in the Domesday survey as Blachenhale, and the parish had one of Cheshire's early ironworks in the 17th and 18th centuries. The area is rural and predominantly agricultural, with small areas of ancient woodland and the nature reserve of Blakenhall Moss, a rejuvenating lowland raised bog. The Crewe-to-Stafford railway line runs through the parish and it is on the proposed route of HS2.

A hammer mill, hammer forge or hammer works was a workshop in the pre-industrial era that was typically used to manufacture semi-finished, wrought iron products or, sometimes, finished agricultural or mining tools, or military weapons. The feature that gave its name to these workshops was the water-driven trip hammer, or set of hammers, used in the process. The shaft, or 'helve', of the hammer was pivoted in the middle and the hammer head was lifted by the action of cams set on a rotating camshaft that periodically depressed the end of the shaft. As it rose and fell, the head of the hammer described an arc. The face of the hammer was made of iron for durability.

Churchill Forge Mill, situated in the Worcestershire village of Churchill, is one of the last water-powered forge mills remaining in an intact state in the UK and as such is an important example of the industrial heritage of the West Midlands. Part of the site has been restored to working condition and is now maintained and operated by the Churchill Forge Trust.

John Kenneth Major ARIBA, FSA, popularly known as Ken Major was an architect, author and world authority on industrial archaeology, particularly windmills, watermills and animal powered machines. As an author, he was known as J Kenneth Major.

The Frohnauer Hammer is an historic hammer mill in Frohnau, a village in the municipality of Annaberg-Buchholz in the Ore Mountains of southeast Germany. The mill is an important witness to proto-industrial development in the Ore Mountains. Of the once-numerous hammer mills only three others remain working in Saxony: the Dorfchemnitz Iron Hammer Mill, the Grünthal Copper Hammer Mill and the Freibergsdorf Hammer Mill.

Richard Streatfeild of Chiddingstone, Kent was an ironmaster who established the financial base for this significant Kentish family.

Patterson's Spade Mill is a water-powered spade mill in Templepatrick, County Antrim, Northern Ireland. Initially a flax and corn mill, it was later converted to a paper mill. Ownership passed to the Patterson family, who had been involved in the spade industry for several generations, converting the mill once again.