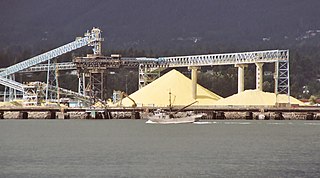

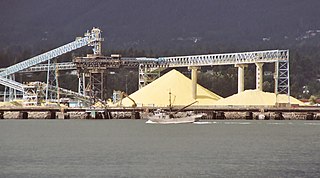

A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys, with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

A tractor is an engineering vehicle specifically designed to deliver a high tractive effort at slow speeds, for the purposes of hauling a trailer or machinery such as that used in agriculture, mining or construction. Most commonly, the term is used to describe a farm vehicle that provides the power and traction to mechanize agricultural tasks, especially tillage, and now many more. Agricultural implements may be towed behind or mounted on the tractor, and the tractor may also provide a source of power if the implement is mechanised.

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

A continuously variable transmission (CVT) is an automated transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds.

A baler or hay baler is a piece of farm machinery used to compress a cut and raked crop into compact bales that are easy to handle, transport, and store. Often, bales are configured to dry and preserve some intrinsic value of the plants bundled. Different types of balers are commonly used, each producing a different type of bale – rectangular or cylindrical, of various sizes, bound with twine, strapping, netting, or wire.

A sprocket, sprocket-wheel or chainwheel is a profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth except for timing pulleys used with toothed belts.

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles.

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery throughout a workshop or an industrial complex. The central power source could be a water wheel, turbine, windmill, animal power or a steam engine. Power was distributed from the shaft to the machinery by a system of belts, pulleys and gears known as millwork.

A chain is a serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression but linear, rigid, and load-bearing in tension. A chain may consist of two or more links. Chains can be classified by their design, which can be dictated by their use:

An idler-wheel is a wheel which serves only to transmit rotation from one shaft to another, in applications where it is undesirable to connect them directly. For example, connecting a motor to the platter of a phonograph, or the crankshaft-to-camshaft gear train of an automobile.

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. The different types of equipment can be classified into four major categories: transport equipment, positioning equipment, unit load formation equipment, and storage equipment.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

A lineshaft roller conveyor or line-shaft conveyor is, as its name suggests, powered by a shaft beneath rollers. These conveyors are suitable for light applications up to 50 kg such as cardboard boxes and tote boxes.

A checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

A drum motor is a geared motor drive enclosed within a steel shell providing a single component driving pulley for conveyor belts.

A conveyor chain is chain that has been designed specifically for chain conveyor systems. It consists of a series of journal bearings that are held together by constraining link plates. Each bearing consists of a pin and a bush on which the chain roller revolves.

The Forbo Siegling Group's headquarters are located in Hanover, Germany. The company is an international manufacturer of conveyor and power transmission belts made of synthetic materials. The group has eight production facilities in Europe, Asia and America, as well as warehouses and workshops in over 50 countries. There are Forbo Siegling service points in more than 300 places all over the world.

Packaging machinery is used throughout all packaging operations, involving primary packages to distribution packs. This includes many packaging processes: fabrication, cleaning, filling, sealing, combining, labeling, overwrapping, palletizing.