Cavitation is a phenomenon in which rapid changes of pressure in a liquid lead to the formation of small vapor-filled cavities, in places where the pressure is relatively low.

A pump is a device that moves fluids, or sometimes slurries, by mechanical action. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps.

A vacuum pump is a device that removes gas molecules from a sealed volume in order to leave behind a partial vacuum. The first vacuum pump was invented in 1650 by Otto von Guericke, and was preceded by the suction pump, which dates to antiquity.

A valve is a device that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

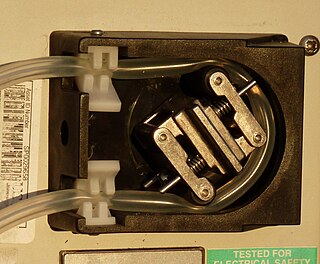

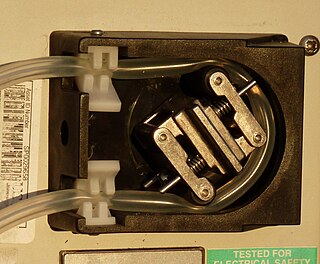

A peristaltic pump is a type of positive displacement pump used for pumping a variety of fluids, they are also commonly known as roller pumps. The fluid is contained within a flexible tube fitted inside a circular pump casing. A rotor with a number of "rollers", "shoes", "wipers", or "lobes" attached to the external circumference of the rotor compresses the flexible tube. As the rotor turns, the part of the tube under compression is pinched closed thus forcing the fluid to be pumped to move through the tube. Additionally, as the tube opens to its natural state after the passing of the cam fluid flow is induced to the pump. This process is called peristalsis and is used in many biological systems such as the gastrointestinal tract. Typically, there will be two or more rollers, or wipers, occluding the tube, trapping between them a body of fluid. The body of fluid is then transported, at ambient pressure, toward the pump outlet. Peristaltic pumps may run continuously, or they may be indexed through partial revolutions to deliver smaller amounts of fluid.

A submersible pump is a device which has a hermetically sealed motor close-coupled to the pump body. The whole assembly is submerged in the fluid to be pumped. The main advantage of this type of pump is that it prevents pump cavitation, a problem associated with a high elevation difference between pump and the fluid surface. Submersible pumps push fluid to the surface as opposed to jet pumps which create a vacuum and rely upon atmospheric pressure. Submersibles are more efficient than jet pumps. Hydraulic submersible pumps (HSP's) use pressurised fluid from the surface to drive a hydraulic motor downhole, rather than an electric motor, and are used in heavy oil applications with heated water as the motive fluid.

An end-face mechanical seal, or a mechanical end-face seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal utilised in rotating equipment, such as pumps, mixers, blowers, and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing to seal the shaft. Since World War II, mechanical seals have replaced packing in many applications.

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurised according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, and/or pipes.

An impeller is a rotor used to increase the pressure and flow of a fluid.

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

A liquid-ring pump is a rotating positive-displacement pump.

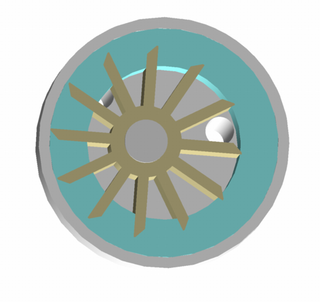

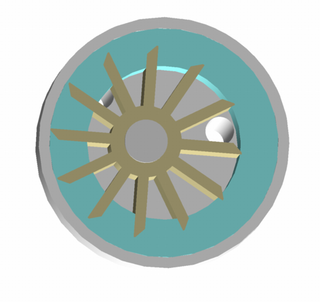

A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside a cavity. In some cases these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates. It was invented by Charles C. Barnes of Sackville, New Brunswick, who patented it on June 16, 1874. There have been various improvements, including a variable vane pump for gases (1909) They are considered less suitable than other vacuum pumps for high-viscosity and high-pressure fluids, and are complex to operate. They can endure short periods of dry operation, and are considered good for low-viscosity fluids.

Diaphragm valves consists of a valve body with two or more ports, an elastomeric diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal, wood or other materials depending on the intended use.

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable parts in high volume.

Artificial lift refers to the use of artificial means to increase the flow of liquids, such as crude oil or water, from a production well. Generally this is achieved by the use of a mechanical device inside the well or by decreasing the weight of the hydrostatic column by injecting gas into the liquid some distance down the well. A newer method called Continuous Belt Transportation (CBT) uses an oil absorbing belt to extract from marginal and idle wells. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface, but often used in naturally flowing wells to increase the flow rate above what would flow naturally. The produced fluid can be oil, water or a mix of oil and water, typically mixed with some amount of gas.

A rotodynamic pump is a kinetic machine in which energy is continuously imparted to the pumped fluid by means of a rotating impeller, propeller, or rotor, in contrast to a positive displacement pump in which a fluid is moved by trapping a fixed amount of fluid and forcing the trapped volume into the pump's discharge. Examples of rotodynamic pumps include adding kinetic energy to a fluid such as by using a centrifugal pump to increase fluid velocity or pressure.

Industrial agitators are machines used in industries that process products in the chemical, food, pharmaceutical and cosmetic industries, in a view of :

A slurry pump is a type of pump designed for pumping liquid containing solid particles. Slurry pumps changes in design and construction to adjust to multiple type of slurry which varies in concentration of solids, size of solid particles, shape of solid particles, and composition of solution. Slurry pump are more robust than liquid pumps; they have added sacrificial material and replaceable wear parts to withstand wear due to abrasion.

Hexoloy is a registered trademark for a pressureless sintered form of alpha silicon carbide. Hexoloy SA is made by sintering silicon carbide powder. This process bonds the powder together to create a self-bonded product which is extremely hard and lightweight. It has a high resistance to corrosion, erosion, high temperature and thermal shock.. It is ideal for applications involving liquid and hot gas exposure, mechanical seal faces, mineral and chemical processing kilns and furnaces. Even with use at high temperatures Hexoloy maintains high strength and stability. Hexoloy has high thermal conductivity, equal to that of stainless steel and 5 times that of alumina and excellent wear resistance – 50% harder than tungsten carbide.