An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength.

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different colours and mechanical, electrical, and chemical properties, but copper typically has the larger proportion. In use since prehistoric times, it is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure.

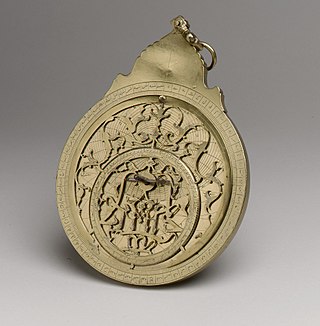

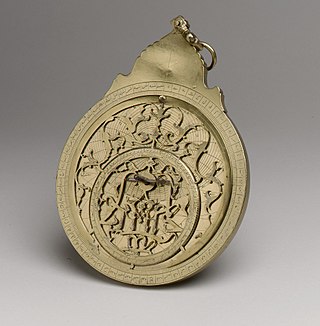

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals and sometimes non-metals, such as phosphorus, or metalloids such as arsenic or silicon. These additions produce a range of alloys that may be harder than copper alone, or have other useful properties, such as strength, ductility, or machinability.

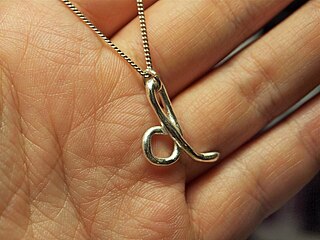

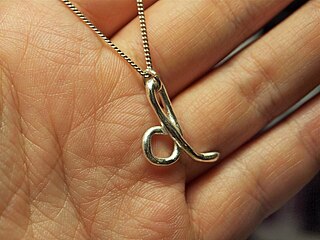

Copper is a chemical element with the symbol Cu and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement.

Duralumin is a trade name for one of the earliest types of age-hardenable aluminium–copper alloys. The term is a combination of Dürener and aluminium. Its use as a trade name is obsolete. Today the term mainly refers to aluminium-copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 and 2024 alloys used in airframe fabrication.

Cupronickel or copper-nickel (CuNi) is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. The copper content typically varies from 60 to 90 percent.

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

Patina is a thin layer that variously forms on the surface of copper, brass, bronze and similar metals and metal alloys or certain stones and wooden furniture, or any similar acquired change of a surface through age and exposure.

Shakudō (赤銅) is a Japanese billon of gold and copper, one of the irogane class of colored metals, which can be treated to develop a black, or sometimes indigo, patina, resembling lacquer. Unpatinated shakudō visually resembles bronze; the dark color is induced by the niiro artificial patination process, involving boiling in a solution, generally including rokushō.

Aluminium bronze is a type of bronze in which aluminium is the main alloying metal added to copper, in contrast to standard bronze or brass. A variety of aluminium bronzes of differing compositions have found industrial use, with most ranging from 5% to 11% aluminium by weight, the remaining mass being copper; other alloying agents such as iron, nickel, manganese, and silicon are also sometimes added to aluminium bronzes.

Metal clay is a crafting medium consisting of very small particles of metal such as silver, gold, bronze, or copper mixed with an organic binder and water for use in making jewelry, beads and small sculptures. Originating in Japan in 1990, metal clay can be shaped just like any soft clay, by hand or using molds. After drying, the clay can be fired in a variety of ways such as in a kiln, with a handheld gas torch, or on a gas stove, depending on the type of clay and the metal in it. The binder burns away, leaving the pure sintered metal. Shrinkage of between 8% and 30% occurs. Alloys such as bronze, sterling silver, and steel also are available.

In metallurgy, non-ferrous metals are metals or alloys that do not contain iron in appreciable amounts.

Spelter is a zinc–lead alloy that ages to resemble bronze, but is softer and has a lower melting point. The name can also refer to a copper–zinc alloy used for brazing, or to pure zinc.

Arsenical bronze is an alloy in which arsenic, as opposed to or in addition to tin or other constituent metals, is combined with copper to make bronze. The use of arsenic with copper, either as the secondary constituent or with another component such as tin, results in a stronger final product and better casting behavior.

Metallurgy in China has a long history, with the earliest metal objects in China dating back to around 3,000 BCE. The majority of early metal items found in China come from the North-Western Region. China was the earliest civilization to use the blast furnace and produce cast iron.

AMPCO METAL is a diversified speciality alloy engineering company working primarily in copper based alloys, non-sparking safety tools and speciality welding products. The Switzerland based company is a manufacturer of engineered alloys of different compositions and properties, intended for specific uses in the aerospace, automotive, energy conservation, manufacturing and other industries. It also produces non-sparking safety tools for the oil industry, as well as the firefighting and fire prevention sectors. Additionally, AMPCO METAL provides engineering, machining and welding advice to the industry, in matters involving its speciality copper, aluminium-bronze and other alloys. AMPCO METAL currently employs approximately 250 people worldwide, and operates a number of divisions and sales offices on three continents.

Diehl Metall is a corporate division of the Diehl Stiftung & Co. KG, a worldwide operating industrial group with its head office in Röthenbach an der Pegnitz near Nuremberg, Germany. The production units of Diehl Metall are situated at 13 locations in Europe, Asia, South America and the US. With 3,420 employees the company generated a turnover of €917 million in 2017. Diehl Metall produces semi-finished products, forgings and rolled products, high-precision stamped parts with plating technologies as well as Schempp+Decker press-fit zones and metal-plastic compound systems. The company provides material development and production, sheet metal forming and forging technology as well as plating, press-fit, overmolding and assembling technology completely in-house.

Irogane is the term for a set of Japanese metals – forms of copper, and copper alloys – treated in niiro patination processes, traditionally used in sword-making, catches for sliding doors, and luxury highlights on larger objects, and in modern times, in jewellery. The alloys contain two to five metals. Some scholars believe that methods similar to those involved in irogane production may also have been used in ancient Egypt and the Roman world, as well as China and Tibet (dzne-ksim).