History

In 1919 Ernst Siegling founded a drive belt factory under his own name. Soon afterwards he started producing traditional, leather flat belts. Early in the 1920s chrome leather upright belts were being made and consisted of many riveted leather belts placed upright.

At the beginning of the 1940s, a patent was registered under the Extremultus brand for a multi-layer flat belt made of nylon and chrome leather. The over 98% energy efficiency offered was a vast increase compared with traditional belt and chain drives.

Automation and efficiency became key issues in the years of the German economic miracle. During this period, Hellmut Siegling, the son of the company's founder, developed a lightweight conveyor belt for inter-company material flow at the request of biscuit manufacturer Hermann Bahlsen. This new belt has since been marketed under the Transilon brand name. It was comparatively thin and light, but at the same time featured low-elongation, was dimensionally stable, very quiet to operate and robust and durable into the bargain. The light conveyor belt required much more compact machinery and therefore only a fraction of the space. Consequently, automation in many areas, such as parcel sorting centres or major bakeries, was possible.

Just as they did in the past, today's conveyor belts make high speeds and very small end radii possible. As a result, they enable efficient production and processing, guaranteeing efficient continual material flows and better working conditions.

Back in 1956, the company had already started to found numerous subsidiaries and affiliates abroad. Early companies to be founded were in the US, Switzerland, Mexico, Japan, Italy, France, Sweden, the Netherlands, Denmark, Australia, Austria and Spain. These were joined later by Canada, China, Malaysia, New Zealand, India, Korea, Belgium, the UK, Slovakia, Slovenia, the Czech Republic, Romania, Hungary, Ireland, Russia, Turkey, Indonesia, Brasil, Chile and Singapore.

In 1971, the world's first production machinery for three-metre wide conveyor belts was purchased. Since 1999, conveyor and processing belts, even up to a width of 4.5 metres, have been made using a calendering process.

Over time, several hundred different belt types with specific characteristics for various industries and applications have been developed. New product groups, such as plastic modular belts and plastic timing belts, gradually turned the company into a full-range supplier of belts. In 1994 the company was bought out by the Swiss corporation Forbo Holding. In 2007, Siegling Belting became Forbo Movement Systems

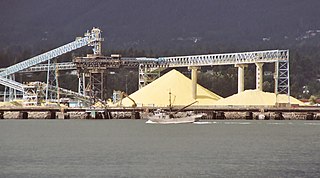

A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys, with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods.

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics manages the flow of goods between the point of origin and the point of consumption to meet the requirements of customers or corporations. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

Logistics automation is the application of computer software or automated machinery to improve the efficiency of logistics operations. Typically this refers to operations within a warehouse or distribution center, with broader tasks undertaken by supply chain engineering systems and enterprise resource planning systems.

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and personal use.

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

A distribution center for a set of products is a warehouse or other specialized building, often with refrigeration or air conditioning, which is stocked with products (goods) to be redistributed to retailers, to wholesalers, or directly to consumers. A distribution center is a principal part, the order processing element, of the entire order fulfillment process. Distribution centers are usually thought of as being demand driven. A distribution center can also be called a warehouse, a DC, a fulfillment center, a cross-dock facility, a bulk break center, and a package handling center. The name by which the distribution center is known is commonly based on the purpose of the operation. For example, a "retail distribution center" normally distributes goods to retail stores, an "order fulfillment center" commonly distributes goods directly to consumers, and a cross-dock facility stores little or no product but distributes goods to other destinations.

Tsubakimoto Chain Co. is a Japanese manufacturer of power transmission and roller chain products. It was founded in Osaka in 1917 as a bicycle chain manufacturer. Later it became the first roller chain manufacturer in Japan approved by Japanese Industrial Standards. Tsubakimoto Chain has the world's largest market share for steel chains for general industrial applications and enjoys the world's top market share for timing drive systems for automobiles. The company is headquartered in Osaka, with its main manufacturing base in Kyotanabe, Kyoto.

Automated Truck Loading Systems - ATLS has been commonly used in the material handling industry to refer to the automation of loading or unloading trucks and trailers with product either on or without pallets, slip sheets, racks, containers, using several different types of automated guided vehicle systems (AGV) or engineered conveyor belt systems that are integrated into vehicles, automating the shipping / receiving and logistics operations.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

The Interroll Worldwide Group is a manufacturer of products for unit-load handling systems, internal logistics and automation.

A vibratory feeder is an instrument that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, and then vibration is used to move the material. They are mainly used to transport a large number of smaller objects.

Dematic is an American supplier of materials handling systems, software and services. With a growth rate of 21.2% in 2020 Dematic was listed as the world's second-largest materials handling systems supplier with a revenue of 3.2 billion USD. The company employs over 6,000 people and has engineering centres and manufacturing facilities in the United States, Germany, United Kingdom, Mexico, Australia, Belgium, China, Italy, Spain, France, Lithuania and Czech Republic. Its customer base includes small, medium and large companies in several other countries across six continents.

A vertical conveyor is a machine which can be used to move products automatically from one level to another. These machines are typically referred to as VRC's. However, the industry does not have universal standard terminology. These lifts can also be referred to as: material lift, parts lift, pallet lift, vertical lift, freight lift, utility lift, box lift, cargo lift, platform lift, baggage lift, vertical conveyor, and dumbwaiter. None of these terms use the word "elevator". This is because that term usually is used when referring to machines that transport people from one level to another and these lifts are not designed or legally allowed to transport people.

Intralox, headquartered in the New Orleans, Louisiana, suburb of Harahan is a manufacturer of conveyor belts. Intralox specializes in modular plastic conveyor belts and related services and equipment.

Steel belts are a type of conveyor belt used in many industries such as food, chemical, wood processing, and transportation.

Honeywell Intelligrated [sic] is a material handling automation and software engineering company based in Mason, Ohio. In 2017, Honeywell Intelligrated reported revenue of $1 billion. Honeywell Intelligrated has production and service locations in the United States, Canada, Mexico, Brazil, and China.

Forbo Holding AG based in Baar ZG is a globally operating Swiss manufacturer of floor coverings and building and construction adhesives as well as power transmission and light conveyor belts.

Packaging machinery is used throughout all packaging operations, involving primary packages to distribution packs. This includes many packaging processes: fabrication, cleaning, filling, sealing, combining, labeling, overwrapping, palletizing.

Warehouse execution systems (WES) are computerized systems used in warehouses and distribution centers to manage and orchestrate the physical flow of products from receiving through shipping. Warehouses are storage facilities for raw materials and parts used in manufacturing operations; distribution centers (DCs) are facilities that store and distribute finished goods to retail locations, consumers, and other end customers.