An electrician is a tradesperson specializing in electrical wiring of buildings, transmission lines, stationary machines, and related equipment. Electricians may be employed in the installation of new electrical components or the maintenance and repair of existing electrical infrastructure. Electricians may also specialize in wiring ships, airplanes, and other mobile platforms, as well as data and cable lines.

Electrical wiring in North America follows the regulations and standards applicable at the installation location. It is also designed to provide proper function, and is also influenced by history and traditions of the location installation.

A residual-current device (RCD), residual-current circuit breaker (RCCB) or ground fault circuit interrupter (GFCI) is an electrical safety device that interrupts an electrical circuit when the current passing through a conductor is not equal and opposite in both directions, therefore indicating an improper flow of current such as leakage current to ground or current flowing to another powered conductor. The device's purpose is to reduce the severity of injury caused by an electric shock. Injury from shock is limited to the time before the electrical circuit is interrupted, but the victim may also sustain further injury, e.g. by falling after receiving a shock. This type of circuit interrupter can not distinguish between current flowing though power carrying conductors that passes through a person from current that passes through electrical equipment and offer no protection when a person touches both conductors at the same time.

The National Electrical Code (NEC), or NFPA 70, is a regionally adoptable standard for the safe installation of electrical wiring and equipment in the United States. It is part of the National Fire Code series published by the National Fire Protection Association (NFPA), a private trade association. Despite the use of the term "national", it is not a Federal law. It is typically adopted by states and municipalities in an effort to standardize their enforcement of safe electrical practices. In some cases, the NEC is amended, altered and may even be rejected in lieu of regional regulations as voted on by local governing bodies.

Appliance classes specify measures to prevent dangerous contact voltages on unenergized parts, such as the metallic casing, of an electronic device. In the electrical appliance manufacturing industry, the following appliance classes are defined in IEC 61140 and used to differentiate between the protective-earth connection requirements of devices.

An arc-fault circuit interrupter (AFCI) or arc-fault detection device (AFDD) is a circuit breaker that breaks the circuit when it detects the electric arcs that are a signature of loose connections in home wiring. Loose connections, which can develop over time, can sometimes become hot enough to ignite house fires. An AFCI selectively distinguishes between a harmless arc, and a potentially dangerous arc.

In electrical engineering, ground and neutral are circuit conductors used in alternating current (AC) electrical systems. The neutral conductor returns current to the supply. To limit the effects of leakage current from higher-voltage systems, the neutral conductor is often connected to earth ground at the point of supply. A ground conductor is not intended to carry current for normal operation of the circuit, but instead connects exposed metallic components to earth ground. A ground conductor only carries significant current if there is a circuit fault that would otherwise energize exposed conductive parts and present a shock hazard. Circuit protection devices may detect a fault to a grounded metal enclosure and automatically de-energize the circuit, or may provide a warning of a ground fault.

Electrical wiring is an electrical installation of cabling and associated devices such as switches, distribution boards, sockets, and light fittings in a structure.

Electrical wiring in the United Kingdom is commonly understood to be an electrical installation for operation by end users within domestic, commercial, industrial, and other buildings, and also in special installations and locations, such as marinas or caravan parks. It does not normally cover the transmission or distribution of electricity to them.

An earthing system or grounding system (US) connects specific parts of an electric power system with the ground, typically the Earth's conductive surface, for safety and functional purposes. The choice of earthing system can affect the safety and electromagnetic compatibility of the installation. Regulations for earthing systems vary among countries, though most follow the recommendations of the International Electrotechnical Commission (IEC). Regulations may identify special cases for earthing in mines, in patient care areas, or in hazardous areas of industrial plants.

Lock out, tag out or lockout–tagout (LOTO) is a safety procedure used to ensure that dangerous equipment is properly shut off and not able to be started up again prior to the completion of maintenance or repair work. It requires that hazardous energy sources be "isolated and rendered inoperative" before work is started on the equipment in question. The isolated power sources are then locked and a tag is placed on the lock identifying the worker and reason the LOTO is placed on it. The worker then holds the key for the lock, ensuring that only they can remove the lock and start the equipment. This prevents accidental startup of equipment while it is in a hazardous state or while a worker is in direct contact with it.

A test light, test lamp, voltage tester, or mains tester is a piece of electronic test equipment used to determine the presence of electricity in a piece of equipment under test. A test light is simpler and less costly than a measuring instrument such as a multimeter, and often suffices for checking for the presence of voltage on a conductor. Properly designed test lights include features to protect the user from accidental electric shock. Non-contact test lights can detect voltage on insulated conductors.

A solenoid voltmeter is a specific type of voltmeter electricians use to test electrical power circuits. It uses a solenoid coil to attract a spring-loaded plunger; the movement of the plunger is calibrated in terms of approximate voltage. It is more rugged than a D'arsonval movement, but neither as sensitive nor as precise.

NEMA connectors are power plugs and sockets used for AC mains electricity in North America and other countries that use the standards set by the US National Electrical Manufacturers Association. NEMA wiring devices are made in current ratings from 15 to 60 amperes (A), with voltage ratings from 125 to 600 volts (V). Different combinations of contact blade widths, shapes, orientations, and dimensions create non-interchangeable connectors that are unique for each combination of voltage, electric current carrying capacity, and grounding system.

In electrical engineering, earth potential rise (EPR), also called ground potential rise (GPR), occurs when a large current flows to earth through an earth grid impedance. The potential relative to a distant point on the Earth is highest at the point where current enters the ground, and declines with distance from the source. Ground potential rise is a concern in the design of electrical substations because the high potential may be a hazard to people or equipment.

In electrical safety testing, portable appliance testing is a process in the United Kingdom, Ireland, New Zealand and Australia by which electrical appliances are routinely checked for safety. The formal term for the process is "in-service inspection & testing of electrical equipment". Testing involves a visual inspection of the equipment and that any flexible power cables are in good condition, and also where required, verification of earthing (grounding) continuity, and a test of the soundness of insulation between the current carrying parts, and any exposed metal that may be touched. The formal limits for pass/fail of these electrical tests vary somewhat depending on the category of equipment being tested.

In electrical engineering, electrical safety testing is essential to make sure electrical products and installations are safe. To meet this goal, governments and various technical bodies have developed electrical safety standards. All countries have their own electrical safety standards that must be complied with. To meet to these standards, electrical products and installations must pass electrical safety tests.

An electrical outlet tester, receptacle tester, or socket tester is a small device containing a 3-prong power plug and three indicator lights, used for quickly detecting some types of incorrectly-wired electrical wall outlets or campsite supplies.

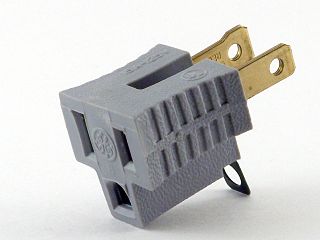

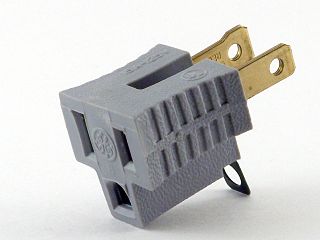

A cheater plug, AC ground lifter or three-prong/two-prong adapter is an adapter that allows a NEMA 5-15P grounding-type plug to connect to a NEMA 1-15R non-grounding receptacle. They are needed to allow appliances with 3-wire power cords to plug into legacy ungrounded receptacles found in older buildings. The use of such an adapter avoids the need to replace receptacles, but is potentially hazardous if the grounding tab is not connected to electrical ground. These adapters are illegal in some jurisdictions, in particular throughout Canada. A safer and more reliable alternative identified in the US and Canadian electrical codes is to replace the outlet with a Ground Fault Circuit Interrupter (GFCI) breaker outlet.

In building wiring installed with separate neutral and protective ground bonding conductors, a bootleg ground is a connection between the neutral side of a receptacle or light fixture and the ground lug or enclosure of the wiring device.