A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps.

Signal processing is an electrical engineering subfield that focuses on analysing, modifying, and synthesizing signals such as sound, images, and scientific measurements. Signal processing techniques can be used to improve transmission, storage efficiency and subjective quality and to also emphasize or detect components of interest in a measured signal.

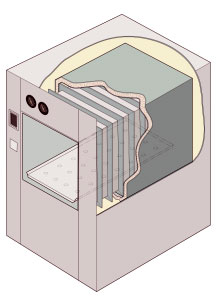

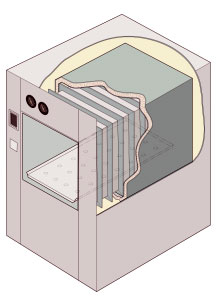

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in the manufacturing of composites.

Laboratory Virtual Instrument Engineering Workbench (LabVIEW) is a system-design platform and development environment for a visual programming language from National Instruments.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

In signal processing, a filter bank is an array of bandpass filters that separates the input signal into multiple components, each one carrying a single frequency sub-band of the original signal. One application of a filter bank is a graphic equalizer, which can attenuate the components differently and recombine them into a modified version of the original signal. The process of decomposition performed by the filter bank is called analysis ; the output of analysis is referred to as a subband signal with as many subbands as there are filters in the filter bank. The reconstruction process is called synthesis, meaning reconstitution of a complete signal resulting from the filtering process.

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

In chemical engineering, process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components.

Scheduling is the process of arranging, controlling and optimizing work and workloads in a production process or manufacturing process. Scheduling is used to allocate plant and machinery resources, plan human resources, plan production processes and purchase materials.

In geotechnical engineering, soil compaction is the process in which stress applied to a soil causes densification as air is displaced from the pores between the soil grains. When stress is applied that causes densification due to water being displaced from between the soil grains, then consolidation, not compaction, has occurred. Normally, compaction is the result of heavy machinery compressing the soil, but it can also occur due to the passage of, for example, animal feet.

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly used term for a PFD is flowsheet.

In metallurgical processes tank leaching is a hydrometallurgical method of extracting valuable material from ore.

A parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces. Parts washers are used in new manufacturing and remanufacturing processes; they are designed to clean, degrease and dry bulk loads of small or large parts in preparation for assembly, inspection, surface treatment, packaging and distribution. Parts washers may be as simple as the manual "sink-on-a-drum" common to many auto repair shops, or they may be very complex, multi-stage units with pass-through parts handling systems. Parts washers are essential in maintenance, repair and remanufacturing operations as well, from cleaning fasteners, nuts, bolts and screws to diesel engine blocks and related parts, rail bearings, wind turbine gears boxes and automotive assemblies.

Pumpable ice (PI) technology uses thin liquids, with the cooling capacity of ice. Pumpable ice is typically a slurry of ice crystals or particles ranging from 5 micrometers to 1 cm in diameter and transported in brine, seawater, food liquid, or gas bubbles of air, ozone, or carbon dioxide.

Hydraulic compressors are a type of compressor that is designed to convert hydraulic power to pneumatic power. It is used across various industries to improve the efficiency of certain types of machinery. Hydraulic compressors have a hydraulic pump to push air through a pipe, which forces a motor to spin. The motor powers the internal air compressor, releasing air in a chamber as a result. Compressors became more popularized in 1799 when Englishman George Medhurst invented a motorized air compressor as a means for propulsion. They have technologically advanced to the point where they can achieve greater force and precision than humans.

A conical plate centrifuge is a type of centrifuge that has a series of conical discs which provides a parallel configuration of centrifugation spaces.

The basic function of a pump is to do work on a liquid. It can be used to transport and compress a liquid. In industries heavy-duty pumps are used to move water, chemicals, slurry, food, oil and so on. Depending on their action, pumps are classified into two types — Centrifugal Pumps and Positive Displacement Pumps. While centrifugal pumps impart momentum to the fluid by motion of blades, positive displacement pumps transfer fluid by variation in the size of the pump’s chamber. Centrifugal pumps can be of rotor or propeller types, whereas positive displacement pumps may be gear-based, piston-based, diaphragm-based, etc. As a general rule, centrifugal pumps are used with low viscosity fluids and positive displacement pumps are used with high viscosity fluids.