A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of the preceding generation engine technology of the turbojet, and a reference to the additional fan stage added. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtight cavity which can be expanded and contracted by operating the handles, and fitted with a valve allowing air to fill the cavity when expanded, and with a tube through which the air is forced out in a stream when the cavity is compressed. It has many applications, in particular blowing on a fire to supply it with air.

Thrust vectoring, also known as thrust vector control (TVC), is the ability of an aircraft, rocket or other vehicle to manipulate the direction of the thrust from its engine(s) or motor(s) to control the attitude or angular velocity of the vehicle.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant, which is a kind of gas-fired power plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

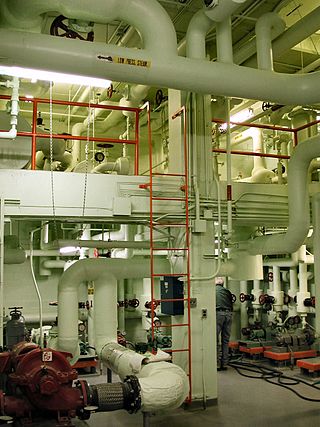

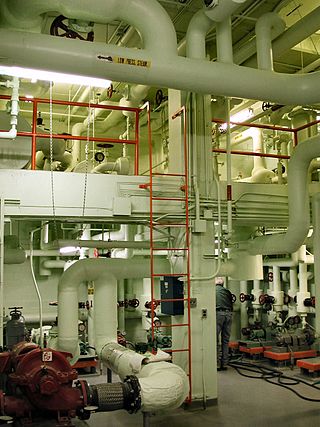

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

A jet engine performs by converting fuel into thrust. How well it performs is an indication of what proportion of its fuel goes to waste. It transfers heat from burning fuel to air passing through the engine. In doing so it produces thrust work when propelling a vehicle but a lot of the fuel is wasted and only appears as heat. Propulsion engineers aim to minimize the degradation of fuel energy into unusable thermal energy. Increased emphasis on performance improvements for commercial airliners came in the 1970s from the rising cost of fuel.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

A expansion joint, or movement joint, is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of building materials. They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

The Hunting H.126 was an experimental aircraft designed and built by British aviation company Hunting Aircraft.

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its yield strength. They are used both for their ability to deform under pressure and to provide a hermetic seal that allows movement.

Process duct work conveys large volumes of hot, dusty air from processing equipment to mills, baghouses to other process equipment. Process duct work may be round or rectangular. Although round duct work costs more to fabricate than rectangular duct work, it requires fewer stiffeners and is favored in many applications over rectangular ductwork.

The Expansion Joint Manufacturers Association is an organization of metal bellows expansion joint manufacturers. It was founded in 1955 to create and maintain a set of standards for quality expansion joint design and manufacturing. The EJMA standards are used worldwide as a reference for the proper selection and application of metallic bellows expansion joints. The standards are a combination of a variety of expansion joint manufacturers' knowledge and experience.

US Bellows is a manufacturer of metal bellows, fabric expansion joints, and metallic expansion joints including refractory lined, hinged, gimbal, slip-type, in-line pressure balanced, and elbow pressure balanced expansion joints. It was acquired by Piping Technology and Products in 1997 from Ketema-U.S. Bellows, Inc. and is now located in Houston, Texas. U.S. Bellows, Inc. provides a variety of expansion joints for piping and duct systems and has been a member of the Expansion Joint Manufacturers Association, Inc. since 2002. In December 2011, U.S. Bellows acquired all bellows assets of the former Lortz Manufacturing companies, doubling its manufacturing capabilities. It is a privately held company owned by Durga D. Agrawal. It is a subsidiary of Piping Technology and Products. These companies provide pipe supports and expansion joints to international companies including Dow Chemical Company, Chevron Corporation, ExxonMobil, and Bechtel.

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

Piping Technology and Products is a privately owned pipe support manufacturing and engineering company headquartered in Houston, Texas, United States. Its wholly owned subsidiaries are US Bellows, Sweco Fab, Fronek Anchor/Darling Enterprise, and Pipe Shields. These companies provide pipe supports, expansion joints, shock and vibration controls, and pre-insulated supports to a variety of industries including LNG, chemical, petrochemical, pulp & paper, and aerospace.

A Refractory lined expansion joint is an assembly used in a pipe line to allow it to expand and contract as climate conditions move from hot to cold and helps to ensure that the system remains functional. The refractory-lining can be vibra cast insulation with anchors, abrasion resistant refractory in hex mesh, gunned insulating refractory, or poured insulating refractory. Refractory lined expansion joints can be hinged, in-line pressure balanced, gimbal, tied-universal depending on the temperature, pressure, movement and flow media conditions.

A Toroidal expansion joint is a metallic assembly that consists of a series of toroidal convolutions which are circular tubes wrapped around pipe ends or weld ends and have a gap at the inside diameter to allow for axial stroke while absorbing changes in expansion or contraction of the pipe line. Convolutions are the portion of the bellows that allow it to be flexible. The convolutions are formed around reinforcing bands so that only the concave portion of the torus allows for flexibility. Toroidal expansion joints are typically used in high pressure applications, where little movement is required, and generally used for heat exchangers. Usually, they are hydraulically formed, but others are free formed. These expansion joints are also referred to as "Omega" bellows due to their shape resembling the Greek letter, Omega.

The Uniform Mechanical Code (UMC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation, inspection and maintenance of HVAC and refrigeration systems. It is designated as an American National Standard.

Metal expansion joints are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. Expansion joints have usage in various sectors, like energy production, paper industry, chemical industry, water treatment, oil and gas. Expansion joints can be used wherever thermal movements or vibration occurs in pipelines.