Hydropower, also known as water power, is the use of falling or fast-running water to produce electricity or to power machines. This is achieved by converting the gravitational potential or kinetic energy of a water source to produce power. Hydropower is a method of sustainable energy production.

A hydraulic ram, or hydram, is a cyclic water pump powered by hydropower. It takes in water at one "hydraulic head" (pressure) and flow rate, and outputs water at a higher hydraulic head and lower flow rate. The device uses the water hammer effect to develop pressure that allows a portion of the input water that powers the pump to be lifted to a point higher than where the water originally started. The hydraulic ram is sometimes used in remote areas, where there is both a source of low-head hydropower and a need for pumping water to a destination higher in elevation than the source. In this situation, the ram is often useful, since it requires no outside source of power other than the kinetic energy of flowing water.

A pump is a device that moves fluids. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps.

A Pelton wheel is an impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead weight like the traditional overshot water wheel. Many earlier variations of impulse turbines existed, but they were less efficient than Pelton's design. Water leaving those wheels typically still had high speed, carrying away much of the dynamic energy brought to the wheels. Pelton's paddle geometry was designed so that when the rim ran at half the speed of the water jet, the water left the wheel with very little speed; thus his design extracted almost all of the water's impulse energy—which made for a very efficient turbine.

A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Pumped-storage hydroelectricity (PSH), or pumped hydroelectric energy storage (PHES), is a type of hydroelectric energy storage used by electric power systems for load balancing. The method stores energy in the form of gravitational potential energy of water, pumped from a lower elevation reservoir to a higher elevation. Low-cost surplus off-peak electric power is typically used to run the pumps. During periods of high electrical demand, the stored water is released through turbines to produce electric power. Although the losses of the pumping process make the plant a net consumer of energy overall, the system increases revenue by selling more electricity during periods of peak demand, when electricity prices are highest. If the upper lake collects significant rainfall or is fed by a river then the plant may be a net energy producer in the manner of a traditional hydroelectric plant.

Hydroelectricity, or hydroelectric power, is electricity produced from hydropower. In 2015, hydropower generated 16.6% of the world's total electricity and 70% of all renewable electricity, and was expected to increase by about 3.1% each year for the next 25 years.

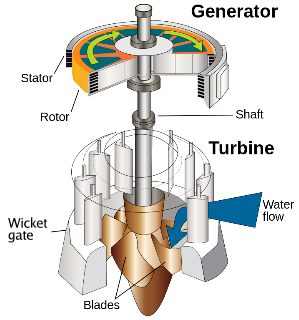

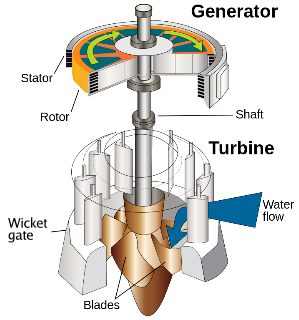

The Kaplan turbine is a propeller-type water turbine which has adjustable blades. It was developed in 1913 by Austrian professor Viktor Kaplan, who combined automatically adjusted propeller blades with automatically adjusted wicket gates to achieve efficiency over a wide range of flow and water level.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

Hydraulic head or piezometric head is a specific measurement of liquid pressure above a vertical datum.

Waterproofing is the process of making an object or structure waterproof or water-resistant so that it remains relatively unaffected by water or resisting the ingress of water under specified conditions. Such items may be used in wet environments or underwater to specified depths.

Micro hydro is a type of hydroelectric power that typically produces from 5 kW to 100 kW of electricity using the natural flow of water. Installations below 5 kW are called pico hydro. These installations can provide power to an isolated home or small community, or are sometimes connected to electric power networks, particularly where net metering is offered. There are many of these installations around the world, particularly in developing nations as they can provide an economical source of energy without the purchase of fuel. Micro hydro systems complement solar PV power systems because in many areas water flow, and thus available hydro power, is highest in the winter when solar energy is at a minimum. Micro hydro is frequently accomplished with a pelton wheel for high head, low flow water supply. The installation is often just a small dammed pool, at the top of a waterfall, with several hundred feet of pipe leading to a small generator housing. In low head sites, generally water wheels and Archimedes screws are used.

A trompe is a water-powered air compressor, commonly used before the advent of the electric-powered compressor. A trompe is somewhat like an airlift pump working in reverse.

Run-of-river hydroelectricity (ROR) or run-of-the-river hydroelectricity is a type of hydroelectric generation plant whereby little or no water storage is provided. Run-of-the-river power plants may have no water storage at all or a limited amount of storage, in which case the storage reservoir is referred to as pondage. A plant without pondage is subject to seasonal river flows, thus the plant will operate as an intermittent energy source. Conventional hydro uses reservoirs, which regulate water for flood control, dispatchable electrical power, and the provision of fresh water for agriculture.

Low-head hydropower refers to the development of hydroelectric power where the head is typically less than 20 metres, although precise definitions vary. Head is the vertical height measured between the hydro intake water level and the water level at the point of discharge. Using only a low head drop in a river or tidal flows to create electricity may provide a renewable energy source that will have a minimal impact on the environment. Since the generated power is a function of the head these systems are typically classed as small-scale hydropower, which have an installed capacity of less than 5MW.

Hydroelectric power in the United States is, as of 2019, the second-largest renewable source of energy in both generation and nominal capacity. In 2019, hydroelectric power produced 38% of the total renewable electricity, and 6.6% of the total U.S. electricity.

Hydraulics is a topic in engineering dealing with the mechanical properties of liquids.

The standard step method (STM) is a computational technique utilized to estimate one-dimensional surface water profiles in open channels with gradually varied flow under steady state conditions. It uses a combination of the energy, momentum, and continuity equations to determine water depth with a given a friction slope , channel slope , channel geometry, and also a given flow rate. In practice, this technique is widely used through the computer program HEC-RAS, developed by the US Army Corps of Engineers Hydrologic Engineering Center (HEC).

The water wall turbine is a water turbine designed to utilize hydrostatic pressure differences for low head hydropower generation. It supports bidirectional inflow operation using radial blades that rotate around a horizontal axis. The water wall turbine is suitable for energy extraction from tidal and freshwater currents. For tidal power installations, the turbine operates in both directions as the tide ebbs and flows.