Polyurethane is a polymer composed of organic units joined by carbamate (urethane) links. While most polyurethanes are thermosetting polymers that do not melt when heated, thermoplastic polyurethanes are also available.

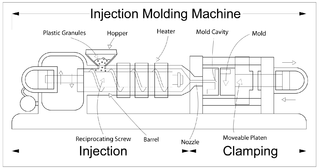

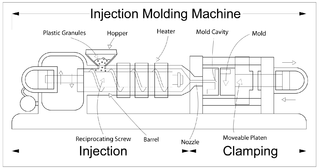

Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould. Injection moulding can be performed with a host of materials mainly including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and injected (Forced) into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers which do not melt during the injection moulding of some lower temperature thermoplastics, can be used for some simple injection moulds.

A vacuum chamber is a rigid enclosure from which air and other gases are removed by a vacuum pump. This results in a low-pressure environment within the chamber, commonly referred to as a vacuum. A vacuum environment allows researchers to conduct physical experiments or to test mechanical devices which must operate in outer space or for processes such as vacuum drying or vacuum coating. Chambers are typically made of metals which may or may not shield applied external magnetic fields depending on wall thickness, frequency, resistivity, and permeability of the material used. Only some materials are suitable for vacuum use.

Pre-preg is "pre-impregnated" composite fibers where a thermoset polymer matrix material, such as epoxy, or a thermoplastic resin is already present. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling; this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure.

Polyamide-imides are either thermosetting or thermoplastic, amorphous polymers that have exceptional mechanical, thermal and chemical resistant properties. Polyamide-imides are used extensively as wire coatings in making magnet wire. They are prepared from isocyanates and TMA in N-methyl-2-pyrrolidone (NMP). A prominent distributor of polyamide-imides is Solvay Specialty Polymers, which uses the trademark Torlon.

Compression Moulding is a method of moulding in which the moulding material, generally preheated, is first placed in an open, heated mould cavity. The mould is closed with a top force or plug member, pressure is applied to force the material into contact with all mould areas, while heat and pressure are maintained until the moulding material has cured. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms.

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable parts in high volume.

A blowing agent is a substance which is capable of producing a cellular structure via a foaming process in a variety of materials that undergo hardening or phase transition, such as polymers, plastics, and metals. They are typically applied when the blown material is in a liquid stage. The cellular structure in a matrix reduces density, increasing thermal and acoustic insulation, while increasing relative stiffness of the original polymer.

Flow injection analysis (FIA) is an approach to chemical analysis. It is accomplished by injecting a plug of sample into a flowing carrier stream. The principle is similar to that of Segmented Flow Analysis (SFA) but no air is injected into the sample or reagent streams.

A thermoset polymer matrix is a synthetic polymer reinforcement first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the space shuttle. In polymer matrix composites, polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements.

Resin casting is a method of plastic casting where a mold is filled with a liquid synthetic resin, which then hardens. It is primarily used for small-scale production like industrial prototypes and dentistry. It can be done by amateur hobbyists with little initial investment, and is used in the production of collectible toys, models and figures, as well as small-scale jewellery production.

RTV Silicone is a type of silicone rubber made from a two-component system available in a hardness range of very soft to medium--usually from 15 to 40 Shore A. RTV silicones can be cured with a catalyst consisting of either platinum or a tin compound such as dibutyltin dilaurate. Applications include low-temperature over-molding, making molds for reproducing, and lens applications for some optically clear grades.

Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material. Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. OOA curing achieves the desired fiber content and elimination of voids by placing the layup within a closed mold and applying vacuum, pressure, and heat by means other than an autoclave. An RTM press is the typical method of applying heat and pressure to the closed mold. There are several out of autoclave technologies in current use including resin transfer molding (RTM), Same Qualified Resin Transfer Molding (SQRTM), vacuum-assisted resin transfer molding (VARTM), and balanced pressure fluid molding. The most advanced of these processes can produce high-tech net shape aircraft components.

Low Pressure Molding (LPM) with polyamide and polyolefin (hot-melt) materials is a process typically used to encapsulate and environmentally protect electronic components. The purpose is to protect electronics against moisture, dust dirt and vibration. Low Pressure Molding is also used for sealing connectors and molding grommets and strain reliefs.

Fluidisation is a phenomenon whereby solid particulate is placed under certain conditions to cause it to behave like a fluid. A fluidized bed is a system conceived to facilitate the fluidisation. Fluidized beds have a wide range of applications including but not limited to: assisting with chemical reactions, heat transfer, mixing and drying. A recent concept devised and patented by Outotec, "An annular fluidized bed consists of a large central nozzle surrounded be a stationary fluidized".

A void is a pore that remains unfilled with polymer and fibers in a composite material. Voids are typically the result of poor manufacturing of the material and are generally deemed undesirable. Voids can affect the mechanical properties and lifespan of the composite. They degrade mainly the matrix-dominated properties such as interlaminar shear strength, longitudinal compressive strength, and transverse tensile strength. Voids can act as crack initiation sites as well as allow moisture to penetrate the composite and contribute to the anisotropy of the composite. For aerospace applications, a void content of approximately 1% is still acceptable, while for less sensitive applications, the allowance limit is 3-5%. Although a small increase in void content may not seem to cause significant issues, a 1-3% increase in void content of carbon fiber reinforced composite can reduce the mechanical properties by up to 20% Void content in composites is represented as a ratio, also called void ratio, where the volume of voids, solid material, and bulk volume are taken into account. Void ratio can be calculated by the formula below where e is the void ratio of the composite, Vv is the volume of the voids, and Vt is the volume of the bulk material.

Multi-material injection molding (MMM) is the process of molding two or more different materials into one plastic part at one time. As is the case in traditional injection molding, multi material injection molding uses materials that are at or near their melting point so that the semi-liquidous (viscous) material can fill voids and cavities within a pre-machined mold, thus taking on the desired shape of designed tooling. In general, advantages of MMM over other production techniques include, but are not limited to, creating parts that have an elastic modulus that varies with location on the part, creating a single-structure part with different regional materials, and also creating a single part with multiple independent polymer colors. Applications range from simple household items like a toothbrush to more heavy duty construction of items like power tools.

Transfer molding is a manufacturing process where casting material is forced into a mold. Transfer molding is different from compression molding in that the mold is enclosed [Hayward] rather than open to the fill plunger resulting in higher dimensional tolerances and less environmental impact. Compared to injection molding, transfer molding uses higher pressures to uniformly fill the mold cavity. This allows thicker reinforcing fiber matrices to be more completely saturated by resin. Furthermore, unlike injection molding the transfer mold casting material may start the process as a solid. This can reduce equipment costs and time dependency. The transfer process may have a slower fill rate than an equivalent injection molding processes.