A heat pump is a device that transfers heat energy from a source of heat to what is called a heat sink. Heat pumps move thermal energy in the opposite direction of spontaneous heat transfer, by absorbing heat from a cold space and releasing it to a warmer one. A heat pump uses a small amount of external power to accomplish the work of transferring energy from the heat source to the heat sink. The most common design of a heat pump involves four main components – a condenser, an expansion valve, an evaporator and a compressor. The heat transfer medium circulated through these components is called refrigerant.

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species, either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system.

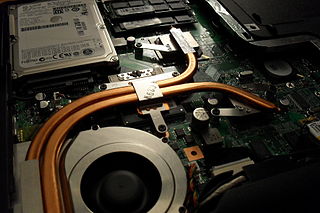

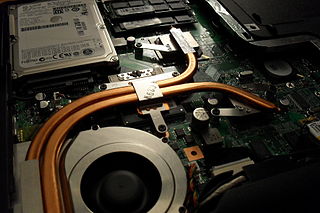

A heat pipe is a heat-transfer device that combines the principles of both thermal conductivity and phase transition to effectively transfer heat between two solid interfaces.

Joule heating, also known as Ohmic heating and resistive heating, is the process by which the passage of an electric current through a conductor produces heat.

The Rankine cycle is a model used to predict the performance of steam turbine systems. It was also used to study the performance of reciprocating steam engines. The Rankine cycle is an idealized thermodynamic cycle of a heat engine that converts heat into mechanical work while undergoing phase change. It is an idealized cycle in which friction losses in each of the four components are neglected. The heat is supplied externally to a closed loop, which usually uses water as the working fluid. It is named after William John Macquorn Rankine, a Scottish polymath and Glasgow University professor.

Thermosiphon is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those utilized in a wood fire chimney or solar chimney.

A binary cycle power plant is a type of geothermal power plant that allows cooler geothermal reservoirs to be used than is necessary for dry steam and flash steam plants. As of 2010, flash steam plants are the most common type of geothermal power generation plants in operation today, which use water at temperatures greater than 182 °C that is pumped under high pressure to the generation equipment at the surface. With binary cycle geothermal power plants, pumps are used to pump hot water from a geothermal well, through a heat exchanger, and the cooled water is returned to the underground reservoir. A second "working" or "binary" fluid with a low boiling point, typically a butane or pentane hydrocarbon, is pumped at fairly high pressure through the heat exchanger, where it is vaporized and then directed through a turbine. The vapor exiting the turbine is then condensed by cold air radiators or cold water and cycled back through the heat exchanger.

Thermal desorption is an environmental remediation technology that utilizes heat to increase the volatility of contaminants such that they can be removed (separated) from the solid matrix. The volatilized contaminants are then either collected or thermally destroyed. A thermal desorption system therefore has two major components; the desorber itself and the offgas treatment system. Thermal desorption is not incineration.

GeoMelt is a process by which dangerous, contaminated material is mixed with clean soil, a blend of industrial minerals, and/or glass frit and melted to create an extremely hard and leach-resistant glass product. Vitrification immobilizes nearly all of the inorganic contaminants present in the initial mixture by incorporation into the glass matrix. Organic wastes in the melt are destroyed by pyrolysis and gaseous contaminants released during the melting process are treated separately.

Low-temperature thermal desorption (LTTD), also known as low-temperature thermal volatilization, thermal stripping, and soil roasting, is an ex-situ remedial technology that uses heat to physically separate petroleum hydrocarbons from excavated soils. Thermal desorbers are designed to heat soils to temperatures sufficient to cause constituents to volatilize and desorb from the soil. Although they are not designed to decompose organic constituents, thermal desorbers can, depending upon the specific organics present and the temperature of the desorber system, cause some organic constituents to completely or partially decompose. The vaporized hydrocarbons are generally treated in a secondary treatment unit prior to discharge to the atmosphere. Afterburners and oxidizers destroy the organic constituents. Condensers and carbon adsorption units trap organic compounds for subsequent treatment or disposal.

Soil vapor extraction (SVE) is a physical treatment process for in situ remediation of volatile contaminants in vadose zone (unsaturated) soils. SVE is based on mass transfer of contaminant from the solid (sorbed) and liquid phases into the gas phase, with subsequent collection of the gas phase contamination at extraction wells. Extracted contaminant mass in the gas phase is treated in aboveground systems. In essence, SVE is the vadose zone equivalent of the pump-and-treat technology for groundwater remediation. SVE is particularly amenable to contaminants with higher Henry’s Law constants, including various chlorinated solvents and hydrocarbons. SVE is a well-demonstrated, mature remediation technology and has been identified by the U.S. Environmental Protection Agency (EPA) as presumptive remedy.

A thermal blanket is a device used in thermal desorption to clean soil contamination. The primary function of a thermal blanket is to heat the soil to the boiling point of the contaminants so that they break down. A vacuum pulls the resulting gas into a separate air cleaner that may use various methods, such as carbon filters and high-heat ovens, to completely destroy the contaminants. Aside from evaporation and volatilization, the contaminants may also be removed from the soil through other mechanisms such as steam distillation, pyrolysis, oxidation, and other chemical reactions.

Groundwater remediation is the process that is used to treat polluted groundwater by removing the pollutants or converting them into harmless products. Groundwater is water present below the ground surface that saturates the pore space in the subsurface. Globally, between 25 per cent and 40 per cent of the world's drinking water is drawn from boreholes and dug wells. Groundwater is also used by farmers to irrigate crops and by industries to produce everyday goods. Most groundwater is clean, but groundwater can become polluted, or contaminated as a result of human activities or as a result of natural conditions.

Electrical resistance heating (ERH) is an intensive in situ environmental remediation method that uses the flow of alternating current electricity to heat soil and groundwater and evaporate contaminants. Electric current is passed through a targeted soil volume between subsurface electrode elements. The resistance to electrical flow that exists in the soil causes the formation of heat; resulting in an increase in temperature until the boiling point of water at depth is reached. After reaching this temperature, further energy input causes a phase change, forming steam and removing volatile contaminants. ERH is typically more cost effective when used for treating contaminant source areas.

Electrokinetics remediation, also termed electrokinetics, is a technique of using direct electric current to remove organic, inorganic and heavy metal particles from the soil by electric potential. The use of this technique provides an approach with minimum disturbance to the surface while treating subsurface contaminants.

Electro Thermal Dynamic Stripping Process (ET-DSP) is a patented in situ thermal environmental remediation technology, created by McMillan-McGee Corporation, for cleaning contaminated sites. ET-DSP uses readily available three phase electric power to heat the subsurface with electrodes. Electrodes are placed at various depths and locations in the formation. Electric current to each electrode is controlled continuously by computer to uniformly heat the target contamination zone.

In situ chemical oxidation (ISCO), a form of advanced oxidation processes and advanced oxidation technology, is an environmental remediation technique used for soil and/or groundwater remediation to reduce the concentrations of targeted environmental contaminants to acceptable levels. ISCO is accomplished by injecting or otherwise introducing strong chemical oxidizers directly into the contaminated medium to destroy chemical contaminants in place. It can be used to remediate a variety of organic compounds, including some that are resistant to natural degradation.

Air sparging, also known as in situ air stripping and in situ volatilization is an in situ remediation technique, used for the treatment of saturated soils and groundwater contaminated by volatile organic compounds (VOCs) like petroleum hydrocarbons which is a widespread problem for the ground water and soil health. The vapor extraction has manifested itself into becoming very successful and practical when it comes to disposing of VOCs. It was used as a new development when it came to saturated zone remediation when using air sparging. Being that the act of it was to inject a hydrocarbon-free gaseous medium into the ground where contamination was found. When it comes to situ air sparging it became an intricate phase process that was proven to be successful in Europe since the 1980s. Currently, there have been further development into bettering the engineering design and process of air sparging.

Aquifer thermal energy storage (ATES) is the storage and recovery of thermal energy in the subsurface. ATES is applied to provide heating and cooling to buildings. Storage and recovery of thermal energy is achieved by extraction and injection of groundwater from aquifers using groundwater wells. Systems commonly operate in a seasonal mode. The groundwater that is extracted in summer, is used for cooling by transferring heat from the building to the groundwater by means of a heat exchanger. Subsequently, the heated groundwater is injected back into the aquifer, which creates a storage of heated groundwater. In wintertime, the flow direction is reversed such that the heated groundwater is extracted and can be used for heating. Therefore, operating an ATES system uses the subsurface as a temporal storage to buffer seasonal variations in heating and cooling demand. When replacing traditional fossil fuel dependent heating and cooling systems, ATES can serve as a cost-effective technology to reduce the primary energy consumption of a building and the associated CO2 emissions.