Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of crude oil from an oil field that cannot be extracted after primary and secondary recovery methods have been completely exhausted. Whereas primary and secondary recovery techniques rely on the pressure differential between the surface and the underground well, enhanced oil recovery functions by altering the physical or chemical properties of the oil itself in order to make it easier to extract. When EOR is used, 30% to 60% or more of a reservoir's oil can be extracted, [1] compared to 20% to 40% using only primary and secondary recovery. [2] [3]

Contents

- Purpose

- Methods

- Injection of CO2 or other gases

- Thermal injection

- Chemical injection

- Other EOR methods

- Economic costs and benefits

- Environmental impacts

- Greenhouse gas emissions

- Government programs and regulations

- United States

- See also

- References

- External links

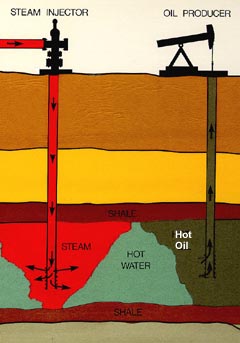

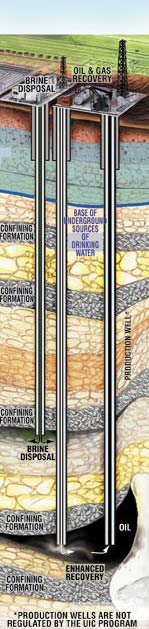

There are four main EOR techniques: carbon dioxide (CO2) injection, gas injection, thermal EOR, and chemical EOR. More advanced, speculative EOR techniques are sometimes called quaternary recovery. [4] [5] [6] [7] Carbon dioxide injection, known as CO2-EOR, is the most common method. In this method, CO2 is injected into a depleted oil field and is mostly left underground.

CO2-EOR is usually performed using CO2 from naturally occurring underground deposits. It is also sometimes performed using CO2 captured from the flue gas of industrial facilities. When EOR is done using CO2 captured from flue gas, the process can prevent some emissions from escaping. However, there is controversy over whether the overall process is beneficial for the climate. EOR operations are energy-intensive, which leads to more emissions, and further emissions are produced when the recovered oil is burned.

EOR adds to the cost of producing oil but can be economically attractive if the price of oil is high. The U.S. Department of Energy estimates that 20 billion tons of captured CO2 could produce 67 billion barrels of economically recoverable oil. As a means of boosting domestic oil production, the US federal tax code began to include incentives for EOR in 1979.