Sources of injection water

Most sources of bulk water can be used for injection. The following sources of water are used for recovery of oil:

Produced water is often used as an injection fluid. This reduces the potential of causing formation damage due to incompatible fluids, although the risk of scaling or corrosion in injection flowlines or tubing remains. Also, the produced water, being contaminated with hydrocarbons and solids, must be disposed of in some manner, and disposal to sea or river will require clean-up treatment of the water stream first. However, the processing required to render produced water fit for reinjection may be equally costly.

As the volumes of water being produced are never sufficient to replace all the production volumes (oil and gas, in addition to water), additional "make-up" water must be provided. Mixing waters from different sources exacerbates the risk of scaling.

Seawater may be the most convenient source for offshore production facilities, and it may be pumped inshore for use in land fields. Where possible, the water intake is placed at sufficient depth to reduce the concentration of algae; however, filtering, deoxygenation, treatment with a biocide is generally required.

Aquifer water from water-bearing formations other than the oil reservoir, but in the same structure, has the advantage of purity and chemical compatibility where available. However this will not be allowed if the aquifer is a source of potable water as, for instance, in Saudi Arabia.

River water will require filtration and treatment with a biocide before injection.

Filters

Filters clean the water and remove impurities, such as sediments, shells, sand, algae and other biological matter. Typical filtration is to 2 micrometres, but depends on reservoir requirements. After filtration the remaining matter in the filtrate is fine enough to avoid blockage of the pores of the reservoir. Sand filters are a commonly used filtration technology. The sand filter has beds with various sizes of sand granules. The water flows through the first, coarsest, layer of sand down to the finest. To clean the filter the process is inverted. After the water is filtered it continues to the de-oxygenation tower. Sand filters are bulky, heavy, have some spill over of sand particles and require chemicals to enhance water quality. A more sophisticated approach is to use automatic self-cleaning backflushable screen filters (suction scanning).

The importance of proper water treatment is crucial; especially with river-, and seawater, intake water quality can vary significantly (algae blooming in spring, storms and current stirring up sediments from the seafloor) which may have significant impact on the performance of the water treatment facilities. This may result in poor water quality, bioclogging of the reservoir and reduction of oil production. [2]

De-oxygenation

Oxygen must be removed from the water because it promotes corrosion and growth of certain bacteria. Bacterial growth in the reservoir can produce hydrogen sulfide, a source of production problems, and may block the pores in the rock.

A deoxygenation tower brings the injection water into contact with a gas stream (gas is readily available in the oilfield). The filtered water flows down the de-oxygenation tower, splashing onto a series of trays or packing causing dissolved air to be transferred to the gas stream.

An alternative or supplementary method, also used as a backup to deoxygenation towers, is to add an oxygen scavenging agent such as sodium bisulfite and ammonium bisulphite.

Another option is to use membrane contactors. Membrane contactors bring the water into contact with an inert gas stream, such as nitrogen, to strip out dissolved oxygen. Membrane contactors have the advantage of being lower weight and compact enabling smaller system designs.

Water injection plants

The configuration of the plant elements described above and their operating conditions are outlined in this section. These examples are the former Amoco North West Hutton installation and the Buzzard installation in the North Sea.

North West Hutton

The water injection system had two design cases [3]

- Case A – Injection of 100,000 barrels of water per day (BWPD) (662 m3/hr), injection pumps operating in parallel with a discharge pressure of 3,000 psi (207 bar)

- Case B – 60,000/65,000 BWPD (397/431 m3/hr), pumps in series /parallel, discharge pressure is 3,000 psi (207 bar) and 30,000/35,000 BWPD (198/232 m3/hr) with a discharge pressure of 5,000 psi (345 bar)

The two duty seawater lift pumps discharged water at 1,590 m3/hr and 30.5 psi (2.1 barg) to the seawater filters. These comprised six dual media (garnet and anthracite) filter beds. Normal flow was downwards. Backwash flow of water and air was upwards with flush water discharged overboard. [3] Backwashing was initiated by a high differential pressure across a filter bed.

Filtered water was routed to the top of the deaerator. This was a vertical vessel 12.6 m high and 4.0 m diameter, the internals comprise a packed bed. Air was stripped from the water by an upflow of fuel gas, gas/air was routed from the top of the vessel to the flare. Oxygen scavenger was injected into the deaerator vessel to remove any residual oxygen. Deaerated water was drawn from the base of the vessel by the deaerator pumps and was transferred to the cold water header operating at 90 psig (6.2 barg).

Process and utility coolers were supplied from the cold water header, warm water from the coolers was routed to the degassing drum where any air or gas was removed. From the degassing drum water passed to the injection filters. [3]

Water was filtered in the water injection filters, one duty and one on standby/backwash. From the filters water was routed to the water injection pumps.

The three water injection pumps each had a capacity of 221 m3/hr with a differential head of 2068.5 metres (209 bar). The pumps discharged to the 3,000 psi manifold and wellheads. The single water injection booster pump (221 m3/hr, 1,379 m (139 bar) differential head) took its suction from the discharge of the water injection pumps and discharged to the 5,000 psi (345 bar) manifold and wellheads.

There were eight water injection wells, each well had a capacity of 15,000 BWPD (99.4 m3/hr). [3]

Buzzard

An alternative configuration and technology is used on the Buzzard field in the North Sea. [4] Seawater lift pumps deliver 4,000m3/hr at 12 barg to the seawater coarse filtration package. After filtration the water is used to cool the cooling medium in the cooling medium plate exchangers. 2322.7 m3/hr of seawater now at 6 barg and 20°C is routed to the fine filters and then to the sulphate removal membrane where reverse osmosis is used to remove sulphate ions from the water. [4]

Desulphated water flows to the top of the deaerator column, this operates at a partial vacuum (0.3 bara) sustained by the deaerator vacuum unit. The deaerator internals comprise three packed beds. Deaerated water is taken from the base of the deaerator by transfer pumps which deliver 1632 m3/hr at 3.6 barg to the degasser surge drum. [4] From the surge drum water is transferred to the water injection pumps which deliver water at up to 250,000 BWPD to up to 11 water injection wells. [5]

Produced water is also injected into the reservoir at up to 350,000 BWPD. [6]

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve and if necessary equipped with extraction devices such as pumpjacks. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in difficult-to-access locations, e.g., offshore. The process of modern drilling for wells first started in the 19th century but was made more efficient with advances to oil drilling rigs and technology during the 20th century.

A diving air compressor is a breathing air compressor that can provide breathing air directly to a surface-supplied diver, or fill diving cylinders with high-pressure air pure enough to be used as a hyperbaric breathing gas. A low pressure diving air compressor usually has a delivery pressure of up to 30 bar, which is regulated to suit the depth of the dive. A high pressure diving compressor has a delivery pressure which is usually over 150 bar, and is commonly between 200 and 300 bar. The pressure is limited by an overpressure valve which may be adjustable.

A media filter is a type of filter that uses a bed of sand, peat, shredded tires, foam, crushed glass, geo-textile fabric, anthracite, crushed granite or other material to filter water for drinking, swimming pools, aquaculture, irrigation, stormwater management, oil and gas operations, and other applications.

Sand filters are used as a step in the water treatment process of water purification.

In terms of water treatment, including water purification and sewage treatment, backwashing refers to pumping water backwards through the filters media, sometimes including intermittent use of compressed air during the process. Backwashing is a form of preventive maintenance so that the filter media can be reused. In water treatment plants, backwashing can be an automated process that is run by local programmable logic controllers (PLCs). The backwash cycle is triggered after a set time interval, when the filter effluent turbidity is greater than a treatment guideline or when the differential pressure across the filter exceeds a set value.

A deaerator is a device that is used for the removal of dissolved gases like oxygen from a liquid.

The rapid sand filter or rapid gravity filter is a type of filter used in water purification and is commonly used in municipal drinking water facilities as part of a multiple-stage treatment system. These systems are complex and expensive to operate and maintain, and therefore less suitable for small communities and developing nations.

Reservoir engineering is a branch of petroleum engineering that applies scientific principles to the fluid flow through a porous medium during the development and production of oil and gas reservoirs so as to obtain a high economic recovery. The working tools of the reservoir engineer are subsurface geology, applied mathematics, and the basic laws of physics and chemistry governing the behavior of liquid and vapor phases of crude oil, natural gas, and water in reservoir rock. Of particular interest to reservoir engineers is generating accurate reserves estimates for use in financial reporting to the SEC and other regulatory bodies. Other job responsibilities include numerical reservoir modeling, production forecasting, well testing, well drilling and workover planning, economic modeling, and PVT analysis of reservoir fluids. Reservoir engineers also play a central role in field development planning, recommending appropriate and cost-effective reservoir depletion schemes such as waterflooding or gas injection to maximize hydrocarbon recovery. Due to legislative changes in many hydrocarbon-producing countries, they are also involved in the design and implementation of carbon sequestration projects in order to minimise the emission of greenhouse gases.

Artificial lift refers to the use of artificial means to increase the flow of liquids, such as crude oil or water, from a production well. Generally this is achieved by the use of a mechanical device inside the well or by decreasing the weight of the hydrostatic column by injecting gas into the liquid some distance down the well. A newer method called Continuous Belt Transportation (CBT) uses an oil absorbing belt to extract from marginal and idle wells. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface, but often used in naturally flowing wells to increase the flow rate above what would flow naturally. The produced fluid can be oil, water or a mix of oil and water, typically mixed with some amount of gas.

Petroleum is a fossil fuel that can be drawn from beneath the Earth's surface. Reservoirs of petroleum are formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil drilling. Seismic surveys and other methods are used to locate oil reservoirs. Oil rigs and oil platforms are used to drill long holes into the earth to create an oil well and extract petroleum. After extraction, oil is refined to make gasoline and other products such as tires and refrigerators. Extraction of petroleum can be dangerous and have led to oil spills.

An oil production plant is a facility which processes production fluids from oil wells in order to separate out key components and prepare them for export. Typical oil well production fluids are a mixture of oil, gas and produced water. An oil production plant is distinct from an oil depot, which does not have processing facilities.

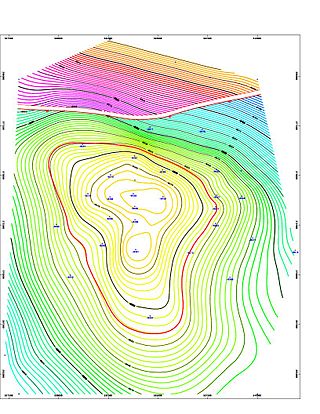

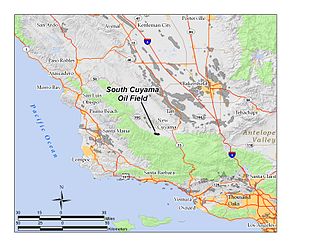

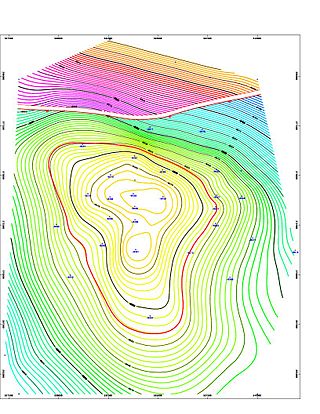

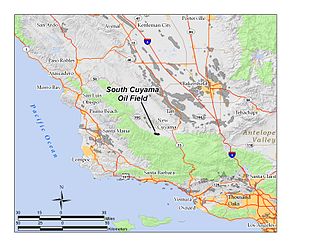

The South Cuyama Oil Field is a large oil and gas field in the Cuyama Valley and the adjacent northern foothills of the Sierra Madre Mountains in northeastern Santa Barbara County, California. Discovered in 1949, and with a cumulative production of around 225 million barrels (35,800,000 m3) of oil, it ranks 27th in size in the state, but is believed to retain only approximately two percent of its original oil, according to the official estimates of the California Department of Oil, Gas, and Geothermal Resources (DOGGR). Of the top forty onshore oil fields in California, it is the most recent to be discovered, but by the end of 2008 only 87 wells remained in production.

Reverse osmosis (RO) is a water purification process that uses a semi-permeable membrane to separate water molecules from other substances. RO applies pressure to overcome osmotic pressure that favors even distributions. RO can remove dissolved or suspended chemical species as well as biological substances, and is used in industrial processes and the production of potable water. RO retains the solute on the pressurized side of the membrane and the purified solvent passes to the other side. It relies on the relative sizes of the various molecules to decide what passes through. "Selective" membranes reject large molecules, while accepting smaller molecules.

The Hutton oil field, located on the UK continental shelf, was the location for the first ever production Tension Leg Platform (TLP).

The West Montalvo Oil Field is a large and productive oil field on the coast of Ventura County, California, in the United States, in and adjacent to the city of Oxnard, California. Discovered in 1947, it has produced approximately 50 million barrels (7,900,000 m3) of oil, retains about 12.2 million barrels recoverable with current technology, and originally contained up to 350 million barrels of oil in both the onshore and offshore areas. The offshore portion of the field is exploited from wells directionally drilled from onshore near McGrath Lake, from within an enclosure above the high-tide line at McGrath State Beach.

The Minjur Desalination Plant is a reverse osmosis, water desalination plant at Kattupalli village, a northern suburb of Chennai, India, on the coast of the Bay of Bengal that supplies water to the city of Chennai. Built on a 60-acre site, it is the largest desalination plant in India. Construction works were carried out by the Indian company IVRCL and the Spanish company Abengoa, under the direction of the Project Manager Fernando Portillo Vallés and the Construction Manager Juan Ignacio Jiménez-Velasco, who returned to Europe after the inauguration of the plant to work on renewable energy projects. Originally scheduled to be operational by January 2009, the work on the plant was delayed due to Cyclone Nisha in October 2008, which damaged a portion of the completed marine works and destroyed the cofferdam meant for the installation of transition pipes. The trial runs were completed in June 2010 and the plant was opened in July 2010. Water from the plant will be utilised chiefly for industrial purposes such as the Ennore Port and North Chennai Thermal Power Station. However, during droughts, water from the plant will be supplied to the public, serving an estimated population of 1,000,000.

Gravity filtration is a method of filtering impurities from solutions by using gravity to pull liquid through a filter. The two main kinds of filtration used in laboratories are gravity and vacuum/suction. Gravity filtration is often used in chemical laboratories to filter precipitates from precipitation reactions as well as drying agents, inadmissible side items, or remaining reactants. While it can also be used to separate out strong products, vacuum filtration is more commonly used for this purpose.

Alwyn North is a major oil and gas field in the United Kingdom sector of the northern North Sea, 160 km east of the Shetland Islands. The field was developed through two bridge-linked offshore platforms and a number of subsea satellite wellheads. Alwyn North has been producing oil and gas since 1987 and is still (2023) in operation.

The Coppermills Water Treatment Works is a large water treatment works in the Lea Valley in east London. Completed in 1969 by the Metropolitan Water Board, it is now owned and operated by Thames Water. In 2009, Coppermills was connected to the Thames Water Ring Main via the Northern Extension Tunnel, enabling the facility to be a major supplier of water to the whole London area. It is capable of supplying a maximum of 680 million litres of water per day.

Pile Cloth Media Filtration is a mechanical process for the separation of organic and inorganic solids from liquids. It belongs to the processes of surface filtration and cake filtration where, in addition to the sieve effect, real filtration effects occur over the depth of the pile layer. Pile Cloth Media Filtration represents a branch of cloth filtration processes and is used for water and wastewater treatment in medium and large scale. In Pile Cloth Media Filtration, three-dimensional textile fabrics are used as filter media. During the filter cleaning of the pile layer the filtration process continues and is not interrupted.