Related Research Articles

Petroleum engineering is a field of engineering concerned with the activities related to the production of Hydrocarbons, which can be either crude oil or natural gas. Exploration and production are deemed to fall within the upstream sector of the oil and gas industry. Exploration, by earth scientists, and petroleum engineering are the oil and gas industry's two main subsurface disciplines, which focus on maximizing economic recovery of hydrocarbons from subsurface reservoirs. Petroleum geology and geophysics focus on provision of a static description of the hydrocarbon reservoir rock, while petroleum engineering focuses on estimation of the recoverable volume of this resource using a detailed understanding of the physical behavior of oil, water and gas within porous rock at very high pressure.

Well drilling is the process of drilling a hole in the ground for the extraction of a natural resource such as ground water, brine, natural gas, or petroleum, for the injection of a fluid from surface to a subsurface reservoir or for subsurface formations evaluation or monitoring. Drilling for the exploration of the nature of the material underground is best described as borehole drilling.

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve that is then mounted with an extraction device such as a pumpjack which allows extraction from the reserve. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in hard to reach areas, e.g., when creating offshore oil platforms. The process of modern drilling for wells first started in the 19th century, but was made more efficient with advances to oil drilling rigs during the 20th century.

In petroleum exploration and development, formation evaluation is used to determine the ability of a borehole to produce petroleum. Essentially, it is the process of "recognizing a commercial well when you drill one".

Baker Hughes Company, organized in Delaware and headquartered in Houston, is one of the world's largest oil field services companies. The company provides products and services for oil well drilling, formation evaluation, completion, production, and reservoir consulting. It operates in over 120 countries, with research and manufacturing facilities in Australia, Singapore, Malaysia, India, Dubai, Saudi Arabia, Italy, Germany, Norway, Oklahoma, Louisiana and Missouri. From 2017 to 2020, the company was majority owned by General Electric (GE); however, GE no longer owns a material stake in the company.

Well logging, also known as borehole logging is the practice of making a detailed record of the geologic formations penetrated by a borehole. The log may be based either on visual inspection of samples brought to the surface or on physical measurements made by instruments lowered into the hole. Some types of geophysical well logs can be done during any phase of a well's history: drilling, completing, producing, or abandoning. Well logging is performed in boreholes drilled for the oil and gas, groundwater, mineral and geothermal exploration, as well as part of environmental and geotechnical studies.

A mud engineer works on an oil well or gas well drilling rig, and is responsible for ensuring the properties of the drilling fluid, also known as drilling mud, are within designed specifications.

Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream. The lower portion is typically held in place with cement. Deeper strings usually are not cemented all the way to the surface, so the weight of the pipe must be partially supported by a casing hanger in the wellhead.

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water wells. One of the functions of drilling mud is to carry cuttings out of the hole.

Mud logging is the creation of a detailed record of a borehole by examining the cuttings of rock brought to the surface by the circulating drilling medium. Mud logging is usually performed by a third-party mud logging company. This provides well owners and producers with information about the lithology and fluid content of the borehole while drilling. Historically it is the earliest type of well log. Under some circumstances compressed air is employed as a circulating fluid, rather than mud. Although most commonly used in petroleum exploration, mud logging is also sometimes used when drilling water wells and in other mineral exploration, where drilling fluid is the circulating medium used to lift cuttings out of the hole. In hydrocarbon exploration, hydrocarbon surface gas detectors record the level of natural gas brought up in the mud. A mobile laboratory is situated by the mud logging company near the drilling rig or on deck of an offshore drilling rig, or on a drill ship.

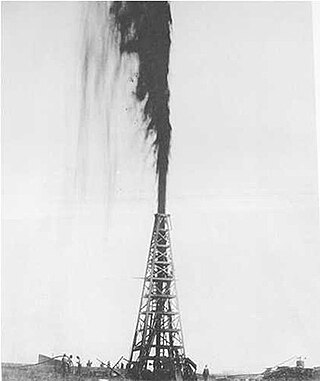

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed. Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil or gas fire.

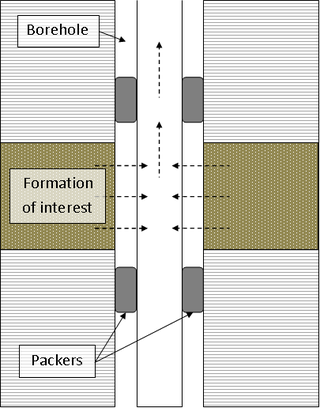

A drill stem test (DST) is a procedure for isolating and testing the pressure, permeability and productive capacity of a geological formation during the drilling of a well. The test is an important measurement of pressure behaviour at the drill stem and is a valuable way of obtaining information on the formation fluid and establishing whether a well has found a commercial hydrocarbon reservoir.

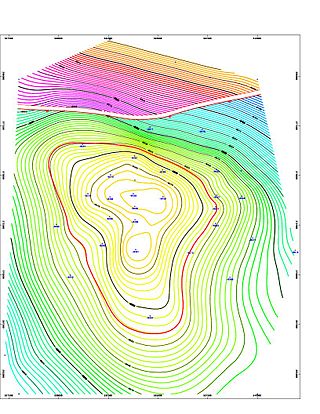

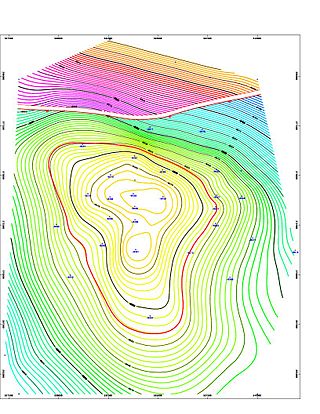

Reservoir engineering is a branch of petroleum engineering that applies scientific principles to the fluid flow through porous medium during the development and production of oil and gas reservoirs so as to obtain a high economic recovery. The working tools of the reservoir engineer are subsurface geology, applied mathematics, and the basic laws of physics and chemistry governing the behavior of liquid and vapor phases of crude oil, natural gas, and water in reservoir rock. Of particular interest to reservoir engineers is generating accurate reserves estimates for use in financial reporting to the SEC and other regulatory bodies. Other job responsibilities include numerical reservoir modeling, production forecasting, well testing, well drilling and workover planning, economic modeling, and PVT analysis of reservoir fluids. Reservoir engineers also play a central role in field development planning, recommending appropriate and cost effective reservoir depletion schemes such as waterflooding or gas injection to maximize hydrocarbon recovery. Due to legislative changes in many hydrocarbon producing countries, they are also involved in the design and implementation of carbon sequestration projects in order to minimise the emission of greenhouse gases.

The Gubkin Russian State University of Oil and Gas is a public university in Moscow, Russia. The university was founded in 1930 and is named after the geologist Ivan Gubkin. The university is colloquially known as Kerosinka, meaning 'kerosene stove'.

Jowfe Oil Technology (JOT) is a state-owned Libyan petroleum services company providing oilfield chemicals and drilling equipment. JOT was founded in 1983 and registered under no. 7102 as a service company owned by the National Oil Corporation (NOC).

Oilfield terminology refers to the jargon used by those working in fields within and related to the upstream segment of the petroleum industry. It includes words and phrases describing professions, equipment, and procedures specific to the industry. It may also include slang terms used by oilfield workers to describe the same.

Offshore oil spill prevention and response is the study and practice of reducing the number of offshore incidents that release oil or hazardous substances into the environment and limiting the amount released during those incidents.

Petroleum production engineering is a subset of petroleum engineering.

Oil well control is the management of the dangerous effects caused by the unexpected release of formation fluid, such as natural gas and/or crude oil, upon surface equipment of oil or gas drilling rigs and escaping into the atmosphere. Technically, oil well control involves preventing the formation gas or fluid (hydrocarbons), usually referred to as kick, from entering into the wellbore during drilling or well interventions.

References

- 1 2 "Petroleum Engineers : Occupational Outlook Handbook: : U.S. Bureau of Labor Statistics". www.bls.gov. Retrieved 2018-02-07.

- ↑ "" Society of Petroleum Engineers . Retrieved on March 25, 2008.