Related Research Articles

James Hargreaves was an English weaver, carpenter and inventor who lived and worked in Lancashire, England. He was one of three men responsible for the mechanisation of spinning: Hargreaves is credited with inventing the spinning jenny in 1764; Richard Arkwright patented the water frame in 1769; and Samuel Crompton combined the two, creating the spinning mule in 1779.

The spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England.

Samuel Crompton was an English inventor and pioneer of the spinning industry. Building on the work of James Hargreaves and Richard Arkwright he invented the spinning mule, a machine that revolutionised the industry worldwide.

John Kay was an English inventor whose most important creation was the flying shuttle, which was a key contribution to the Industrial Revolution. He is often confused with his namesake, who built the first "spinning frame".

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications..

Philippe Henri de Girard was a French engineer and inventor of the first flax spinning frame in 1810, and the person after whom the town of Żyrardów in Poland was named. He was also the uncredited inventor of food preservation using tin cans.

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

Matthew Murray was an English steam engine and machine tool manufacturer, who designed and built the first commercially viable steam locomotive, the twin cylinder Salamanca in 1812. He was an innovative designer in many fields, including steam engines, machine tools and machinery for the textile industry.

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute. It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in niche production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitware market.

John Kay was an English inventor best known for the development of the spinning frame in 1767, which marked an important stage in the development of textile manufacturing during the Industrial Revolution. Born in Warrington in Lancashire, England, Kay was at least the co-constructor of the first spinning frame, and was a claimant to having been its inventor. He is sometimes confused with the unrelated John Kay from Bury, Lancashire, who had invented the flying shuttle, a weaving machine, some thirty years earlier.

John Marshall was a British businessman and politician from Leeds, West Yorkshire, England.

Temple Works is a former flax mill in Holbeck, Leeds, West Yorkshire, England. It was designed by the engineer James Coombe a former pupil of John Rennie; the painter David Roberts; and the architect Joseph Bonomi the Younger. It was built in the Egyptian Revival style for the industrialist John Marshall between 1836 and 1840 to contain a 240 horsepower double-beam engine by Benjamin Hick. Temple Works is the only Grade I listed building in Holbeck.

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny, a carding machine and the throstle.

Flax mills are mills which process flax. The earliest mills were developed for spinning yarn for the linen industry.

Turton is a historical area in the North West of England. It is divided between the ceremonial counties of Lancashire and Greater Manchester. The Turton area is located north of Bolton and south of Blackburn. The area historically formed a township in the ancient parish of Bolton le Moors. The principal village in the township is now known as Chapeltown.

Philippe Henri de Girard patented in France spinning frames for both the dry and wet spinning of flax. His inventions were also patented in England in 1815, in the name of Horace Hall. Little is known about Horace Hall, it is a possible pseudonym. Undoubtedly if he had taken out his patent in England in 1815, the year of the Battle of Waterloo, in a French name there would not have been a lot of enthusiasm for it; possibly even suspicion.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

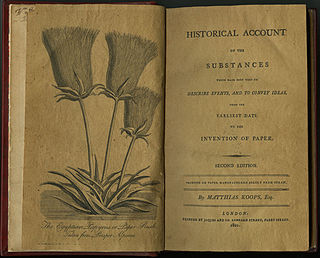

Matthias Koops was a British paper-maker who invented the first practical processes for manufacturing paper from wood pulp, straw, or recycled waste paper, without the necessity of including expensive linen or cotton rags.