Related Research Articles

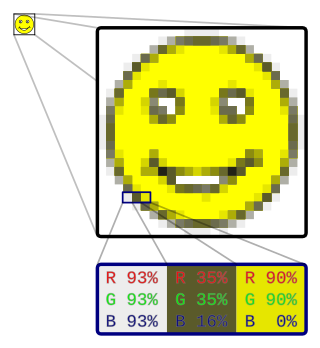

In computer graphics and digital photography, a raster graphic represents a two-dimensional picture as a rectangular matrix or grid of pixels, viewable via a computer display, paper, or other display medium. A raster image is technically characterized by the width and height of the image in pixels and by the number of bits per pixel. Raster images are stored in image files with varying dissemination, production, generation, and acquisition formats.

Vector graphics are a form of computer graphics in which visual images are created directly from geometric shapes defined on a Cartesian plane, such as points, lines, curves and polygons. The associated mechanisms may include vector display and printing hardware, vector data models and file formats, as well as the software based on these data models. Vector graphics are an alternative to raster or bitmap graphics, with each having advantages and disadvantages in specific situations.

A raster image processor (RIP) is a component used in a printing system which produces a raster image also known as a bitmap. Such a bitmap is used by a later stage of the printing system to produce the printed output. The input may be a page description in a high-level page description language such as PostScript, PDF, or XPS. The input can also be or include bitmaps of higher or lower resolution than the output device, which the RIP resizes using an image scaling algorithm.

Color management is the process of ensuring consistent and accurate colors across various devices, such as monitors, printers, and cameras. It involves the use of color profiles, which are standardized descriptions of how colors should be displayed or reproduced.

Digital printing is a method of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers.

Prepress is the term used in the printing and publishing industries for the processes and procedures that occur between the creation of a print layout and the final printing. The prepress process includes the preparation of artwork for press, media selection, proofing, quality control checks and the production of printing plates if required. The artwork is quite often provided by the customer as a print-ready PDF file created in desktop publishing.

An Iris printer is a large-format color inkjet printer designed for prepress proofing. It was introduced in 1985 by Iris Graphics, originally of Stoneham, Massachusetts, and is currently manufactured by the Graphic Communications Group of Eastman Kodak. It is also used in the fine art reproduction market as a final output digital printing press, as in Giclée.

In printing, Preflight is the process of confirming that the digital files required for the printing process are all present, valid, correctly formatted, and of the desired type. The basic idea is to prepare the files to make them feasible for the correct process such as offset printing and eliminate costly errors and facilitate a smooth production. It is a standard prepress procedure in the printing industry. The term originates from the preflight checklists used by pilots. The term was first used in a presentation at the Color Connections conference in 1990 by consultant Chuck Weger, and Professor Ron Bertolina was a pioneer for solutions to preflighting in the 1990s.

Web-to-print, also known as Web2Print, remote publishing or print e-commerce is commercial printing using web sites. Companies and software solutions that deal in web-to-print use standard e-commerce and online services like hosting, website design, and cross-media marketing.

Prinergy is a prepress workflow system created by Creo in 1999 and maintained and sold through Kodak. It is a client/server system that integrates PDF creation, job proofing, imposition, and a raster image processor (RIP) into one unified workflow.

In color management, an ICC profile is a set of data that characterizes a color input or output device, or a color space, according to standards promulgated by the International Color Consortium (ICC). Profiles describe the color attributes of a particular device or viewing requirement by defining a mapping between the device source or target color space and a profile connection space (PCS). This PCS is either CIELAB (L*a*b*) or CIEXYZ. Mappings may be specified using tables, to which interpolation is applied, or through a series of parameters for transformations.

PDF/X is a subset of the ISO standard for PDF. The purpose of PDF/X is to facilitate graphics exchange, and it therefore has a series of printing-related requirements which do not apply to standard PDF files. For example, in PDF/X-1a all fonts need to be embedded and all images need to be CMYK or spot colors. PDF/X-3 accepts calibrated RGB and CIELAB colors, while retaining most of the other restrictions of PDF/X-1a.

IT8 is a set of American National Standards Institute (ANSI) standards for color communications and control specifications. Formerly governed by the IT8 Committee, IT8 activities were merged with those of the Committee for Graphics Arts Technologies Standards in 1994.

PPML is an XML-based industry standard printer language for variable data printing defined by PODi. The industry-wide consortium of 13 companies was initially formed to create PPML, and now has more than 400 member companies.

A contract proof usually serves as an agreement between customer and printer and as a color reference guide for adjusting the press before the final press run. Most contract proofs are a prepress proof.

Within the printing industry, the Approval proofer, also known as the Approval Digital Imaging System or Kodak Approval System, was designed for use in Prepress proofing, especially for the highest quality contract proofs.

"Harlequin (software)" is a raster image processor first released in 1990 under the name ScriptWorks running as a command-line application to render PostScript language files under Unix. It was developed by Harlequin, a software company based in Cambridge, England.

The Academy Color Encoding System (ACES) is a color image encoding system created under the auspices of the Academy of Motion Picture Arts and Sciences. ACES is characterised by a color accurate workflow, with "seamless interchange of high quality motion picture images regardless of source".

Media Standard Print is a publication of the Bundesverband Druck und Medien (BVDM), available on its website. The publication contains instructions on how to produce data and proofs that are to be sent to a printer. It is based on ProcessStandard Offset and therefore on the ISO standards 12647 and 15930. As such, it serves as the foundation for smooth cooperation between customer, prepress service provider and printer during media production, covering data formats, colour spaces, printing conditions, workflows, means of proofing, standards, black composition and much more.

The European Color Initiative (ECI) is an expert group that is concerned with media-neutral reproduction of color data in digital publication systems. It was formed in June 1996 by German publishers Bauer, Burda, Gruner + Jahr and Springer in Hamburg.

References

- Wolfgang Kühn, Martin Grell: JDF: Process Integration, Technology, Product Description, Springer, ISBN 3-540-23560-4

- Doug Sahlin: How to do Everything with Adobe Acrobat X, McGraw-Hill/Osborne Media, ISBN 0-07-225788-1

- Kaj Johansson, Peter Lundberg, Robert Ryberg: A Guide to Graphic Print Production, John Wiley & Sons, ISBN 0-471-76138-9